VTOL vehicles are poised to revolutionize transportation, offering a unique blend of vertical takeoff and landing capabilities that traditional aircraft lack. This in-depth look explores the intricacies of these innovative machines, from their historical roots to the future of urban air mobility.

These vehicles, encompassing a range of designs from helicopters to electric vertical takeoff and landing (eVTOL) craft, present a compelling solution for urban air travel, promising faster and more efficient movement within congested areas. The technology behind VTOL vehicles is rapidly evolving, with significant advancements in propulsion systems and aerodynamic designs shaping their future.

Introduction to VTOL Vehicles

VTOL, or Vertical Take-off and Landing, vehicles represent a unique class of aircraft capable of taking off and landing vertically, unlike traditional fixed-wing aircraft. This distinctive characteristic opens up new possibilities for transportation, particularly in urban environments and remote areas. This approach to flight significantly alters the operational requirements and design considerations compared to conventional aircraft.The key differentiator between VTOL and traditional aircraft lies in their propulsion systems and flight control mechanisms.

Traditional aircraft rely on forward thrust generated by wings to achieve lift, necessitating a runway for takeoff and landing. VTOL vehicles, conversely, generate lift primarily from rotors or other mechanisms, enabling vertical ascent and descent, thereby eliminating the need for runways in certain applications.

Key Differences Between VTOL and Traditional Aircraft

Traditional aircraft, like airliners and private jets, require long runways for takeoff and landing. This constraint significantly impacts their location and operational flexibility. VTOL vehicles, on the other hand, can take off and land vertically, offering advantages in congested urban areas or locations with limited space. This crucial difference fundamentally alters the design and operational requirements for each type of aircraft.

Historical Context of VTOL Vehicle Development

The quest for vertical take-off and landing capabilities has spanned several decades, driven by the need for greater flexibility and accessibility in aviation. Early experiments with rotorcraft and other unconventional designs laid the groundwork for modern VTOL vehicles. The development of more powerful and efficient propulsion systems has been instrumental in the advancement of this technology.

Examples of VTOL Vehicle Types

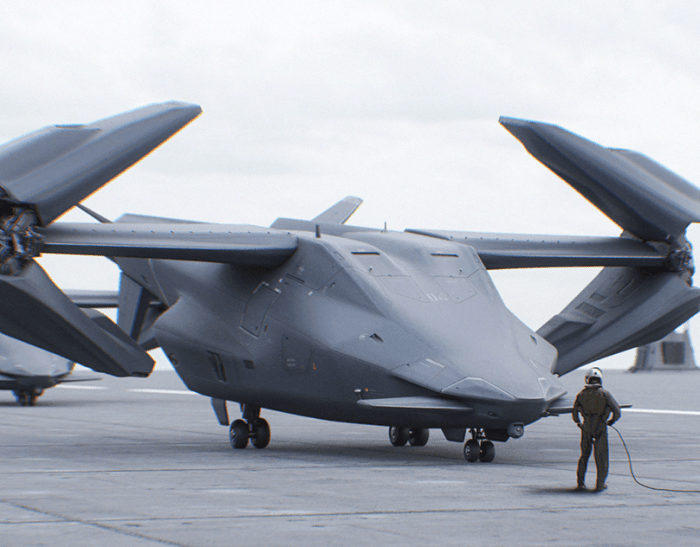

Several types of VTOL vehicles exist, each with its own characteristics and applications. Helicopters, with their rotating blades, are a prime example of a VTOL aircraft. Tilt-rotor aircraft, which can transition between helicopter and fixed-wing configurations, offer a balance of vertical take-off and landing capabilities and the efficiency of fixed-wing flight. More recently, electric vertical take-off and landing (eVTOL) vehicles have emerged as a promising alternative, leveraging advancements in electric propulsion and battery technology.

Comparison of VTOL Vehicle Types

| Vehicle Type | Propulsion | Advantages | Disadvantages | Operational Limitations |

|---|---|---|---|---|

| Helicopters | Rotating blades (rotors) | Excellent vertical maneuverability, ability to hover | Lower speed compared to fixed-wing aircraft, relatively noisy, lower range | Limited speed and range, susceptible to wind conditions |

| Tilt-rotor Aircraft | Combination of rotors and fixed wings | High speed in forward flight, vertical take-off and landing | Complex design, potentially higher cost | Transition between modes can be challenging in certain conditions |

| eVTOL | Electric motors and propellers/rotors | Quiet operation, lower emissions, potential for urban deployment | Limited range compared to other types, battery technology challenges | Battery life and charging infrastructure are critical considerations |

This table provides a concise comparison of various VTOL vehicle types, highlighting their distinct characteristics, potential advantages, and associated drawbacks. Further research into specific models and technologies is recommended for a deeper understanding of each category.

Propulsion Systems for VTOL

Vertical Take-Off and Landing (VTOL) vehicles require unique propulsion systems to enable both vertical lift and horizontal flight. These systems must balance the demands of rapid acceleration for vertical take-off and sustained, efficient horizontal flight. Different approaches offer varying advantages and disadvantages in terms of performance, cost, and environmental impact.Various propulsion technologies are employed in VTOL aircraft, each with its own set of characteristics.

Understanding these technologies is crucial for evaluating the suitability of different VTOL designs for specific applications. The efficiency and cost-effectiveness of these systems directly influence the overall viability of VTOL vehicles.

Types of Propulsion Systems

Different VTOL designs utilize various propulsion methods. A diverse range of systems, including electric, hybrid, and jet-based propulsion, is employed in current and emerging VTOL vehicles. Each system has distinct attributes that influence its suitability for different VTOL applications.

Electric Propulsion

Electric propulsion systems, utilizing electric motors and batteries, are increasingly popular for VTOL vehicles. These systems offer high efficiency in both vertical and horizontal flight modes. Electric motors are capable of generating high thrust-to-weight ratios and are generally quieter than other systems. Furthermore, advancements in battery technology are continuously improving energy density and reducing charging times, increasing the range and practical application of VTOL vehicles.

Hybrid Propulsion

Hybrid propulsion systems combine electric and other forms of propulsion, such as jet engines or gas turbines. This approach leverages the strengths of both technologies. For example, a hybrid system might utilize electric motors for vertical take-off and landing and a gas turbine for extended horizontal flight. This combination aims to maximize efficiency across the flight spectrum, mitigating the limitations of either technology alone.

Jet Propulsion

Jet propulsion, often utilizing turbojet or turbofan engines, is a well-established technology for fixed-wing aircraft. In VTOL applications, jet engines may be employed for the horizontal flight phase. However, the challenges associated with generating sufficient vertical thrust often necessitate specialized designs or the integration of additional systems to achieve VTOL capabilities.

Comparison of Propulsion Systems

| Propulsion System | Advantages | Disadvantages | Efficiency (Relative) |

|---|---|---|---|

| Electric | High efficiency, quiet operation, low maintenance, and potentially lower cost | Limited range due to battery capacity, and slower acceleration | High |

| Hybrid | Combines strengths of electric and other propulsion systems, potentially extending range | Complexity in design and control, potentially higher cost | Medium to High |

| Jet | High speed and range, established technology | Lower efficiency in vertical flight, high noise levels, and higher maintenance requirements | Low to Medium |

Design Considerations for VTOL Propulsion Systems

Design considerations for VTOL propulsion systems include achieving a balance between vertical lift capability and horizontal flight efficiency. This includes optimizing the number and arrangement of propellers or engines, considering the weight and size limitations of the vehicle, and balancing the need for high thrust in vertical flight with the need for efficiency in horizontal flight. Sophisticated control systems are essential to manage the complex interactions between multiple propulsion units and the vehicle’s aerodynamics during both vertical and horizontal phases of flight.

Aerodynamics and Flight Mechanics

VTOL (Vertical Take-off and Landing) aircraft present unique aerodynamic challenges compared to conventional fixed-wing aircraft. The need for both vertical lift and forward thrust, coupled with the complex interactions between these forces, necessitates specialized design considerations. Understanding these intricacies is crucial for efficient VTOL flight and safe operation.The flight mechanics of VTOL vehicles involve a delicate interplay between lift and thrust generation, as well as complex control systems to manage the transition between vertical and horizontal flight.

The unique configuration of these vehicles requires tailored control strategies to ensure stable and predictable performance throughout all flight phases.

Aerodynamic Challenges of VTOL Flight

VTOL aircraft face the challenge of generating lift in a vertical orientation, often requiring significantly larger wing surfaces or rotors compared to conventional aircraft. This larger surface area can increase drag, particularly during transitions between vertical and horizontal flight. Additionally, the interaction between lift and thrust can produce complex aerodynamic forces, making precise control crucial. Careful design is necessary to minimize drag and maximize efficiency during all flight phases.

Flight Mechanics Principles Specific to VTOL Aircraft

VTOL aircraft rely on a combination of lift and thrust to achieve flight. The vertical lift is often generated by rotors, tilting propellers, or vectored thrust. Horizontal thrust is usually provided by the same propellers, but in a horizontal configuration. The precise control of these forces, particularly during transitions, is vital for stable and controlled flight. Understanding and managing the interplay of these forces is key to VTOL flight mechanics.

Control Systems Required for VTOL Vehicles

Sophisticated control systems are essential for VTOL aircraft. These systems must precisely manage the transition between vertical and horizontal flight, and control the interplay between lift and thrust forces. Advanced sensors, actuators, and control algorithms are vital for precise maneuvers and stability during takeoff, landing, and transitioning between vertical and horizontal phases of flight. The control systems must account for variations in wind conditions and other environmental factors.

Lift and Thrust Generation in VTOL Vehicles

Lift and thrust are generated in VTOL aircraft through various mechanisms. Rotorcraft use rotating blades to generate lift, while tilt-rotor aircraft employ tilting propellers to achieve both vertical and horizontal flight. Vectored thrust aircraft utilize thrust vectoring technology to control the direction of thrust, allowing for vertical lift. The specific method employed influences the design and performance characteristics of the VTOL vehicle.

Mechanisms for Vertical Takeoff and Landing

Vertical takeoff and landing (VTOL) is achieved through a combination of lift and thrust generation, often with specific configurations tailored to achieve the required forces. Rotorcraft use rotating blades for vertical lift, whereas tilt-rotor aircraft tilt their propellers to achieve vertical lift. Vectored thrust aircraft employ thrust vectoring systems for precise vertical control. The mechanisms are designed to provide controlled and stable vertical takeoff and landing, enabling the vehicle to operate from confined spaces.

Design and Construction

Vertical takeoff and landing (VTOL) vehicles present unique design challenges compared to conventional aircraft. Their ability to both take off and land vertically necessitates innovative solutions for propulsion, control, and structure. This necessitates a careful consideration of the trade-offs between performance, safety, and cost.

Unique Design Considerations

VTOL vehicles require a highly integrated design. The systems for vertical lift, horizontal flight, and landing must be carefully coordinated to ensure safe and efficient operation. This necessitates meticulous attention to weight distribution, center of gravity, and overall structural integrity. Moreover, the integration of multiple propulsion systems, flight control systems, and other onboard equipment requires precise engineering and careful management of space constraints.

The design must accommodate the complexities of both vertical and horizontal flight, accounting for the substantial differences in aerodynamic forces and control requirements in each mode.

Materials and Construction Techniques

A variety of materials and construction techniques are employed in VTOL aircraft. Lightweight yet strong materials like carbon fiber composites and advanced alloys are commonly used to reduce weight and enhance structural rigidity. Advanced manufacturing techniques, including 3D printing and other additive manufacturing methods, are also increasingly employed to create complex geometries and optimize material usage. This approach not only minimizes weight but also enables intricate designs that might be difficult or impossible to achieve with traditional manufacturing processes.

The choice of material and construction technique is highly dependent on the specific requirements of the vehicle, including payload capacity, operating conditions, and cost constraints.

Challenges Associated with Integrating Multiple Systems

Integrating multiple systems within a VTOL vehicle presents considerable challenges. The complex interactions between propulsion systems, flight control systems, and other onboard equipment require careful coordination and integration to ensure smooth and reliable operation. Potential conflicts between the different systems must be anticipated and mitigated to prevent safety hazards. Issues like weight distribution, thermal management, and electrical power distribution must also be meticulously addressed to ensure optimal performance and safety.

Airframe Design and Components

The airframe of a VTOL vehicle is designed to accommodate both vertical and horizontal flight modes. It must provide a stable platform for the propulsion systems and maintain structural integrity during rapid transitions between modes. The design often incorporates retractable landing gear for horizontal flight and potentially specialized components for vertical lift. Critical components, such as the vertical lift units and the horizontal flight wings, require sophisticated design to maximize efficiency and performance.

Careful consideration must be given to the aerodynamic characteristics of each component in both vertical and horizontal flight configurations.

Comparison of VTOL Designs

| Vehicle Type | Size (m) | Weight (kg) | Structure |

|---|---|---|---|

| eVTOL (Electric Vertical Take-Off and Landing) | ~6-10 | ~500-1500 | Composite materials, potentially with 3D-printed components |

| Hybrid VTOL | ~8-12 | ~800-2000 | Combination of composite and metallic materials, possibly with rotor-wing configuration |

| Rotorcraft-based VTOL | ~7-15 | ~1000-3000 | Traditional rotorcraft structure with modifications for vertical flight |

The table above provides a basic comparison of different VTOL vehicle designs. The specific dimensions and weight will vary based on the intended use case, such as passenger capacity, cargo weight, or range requirements. The table highlights the potential differences in size, weight, and construction materials based on the chosen design approach.

Operational Considerations: VTOL Vehicles

Vertical takeoff and landing (VTOL) vehicles present unique operational challenges compared to conventional aircraft. Careful consideration of various factors, including safety protocols, environmental impact, and maintenance procedures, is crucial for their effective and responsible deployment. Different VTOL designs will have varying operational profiles, necessitating tailored approaches for each.

Operational Requirements

VTOL vehicles demand specific operational requirements to ensure safe and efficient flight. These include precise control systems for vertical takeoff and landing, advanced sensor suites for situational awareness, and robust communication protocols for real-time data exchange. Furthermore, the specific operational environments and mission parameters will determine the required vehicle characteristics. For instance, a VTOL vehicle designed for urban air mobility will need different specifications compared to one intended for cargo transport.

Safety and Regulatory Aspects

Safety is paramount in VTOL operations. Comprehensive safety regulations, encompassing pilot training, maintenance standards, and emergency procedures, are essential. Rigorous testing and certification processes are vital to guarantee the safety of both the operators and the public. The integration of advanced safety features, like redundant control systems and automatic fail-safe mechanisms, further enhances operational safety. Regulatory frameworks are evolving to address the unique challenges posed by VTOL vehicles.

This involves defining airspace usage, noise restrictions, and emergency response protocols.

Environmental Impact

The environmental impact of VTOL vehicles is a significant concern. Different propulsion systems have varying environmental footprints. Electric VTOL vehicles generally have a lower environmental impact than those relying on traditional jet fuels. However, factors like battery production, charging infrastructure, and operational efficiency contribute to the overall environmental profile. Assessing the life cycle of different VTOL propulsion systems and optimizing operational procedures will be critical to minimizing the environmental footprint.

Maintenance Procedures

Efficient maintenance procedures are crucial for the reliable operation of VTOL vehicles. These procedures should address the specific components and systems of the VTOL, accounting for the complex interplay of mechanical, electrical, and software systems. Regular inspections, preventative maintenance, and timely repairs are necessary to ensure optimal performance and extend the lifespan of the vehicle. This includes standardized procedures for component replacement and maintenance scheduling.

VTOL Use Scenarios

VTOL vehicles offer diverse application scenarios. Personal transportation is a potential application, providing a faster and more convenient mode of transport, especially in congested urban areas. Cargo delivery is another use case, enabling rapid and reliable delivery of goods. In emergency situations, VTOL vehicles can provide rapid access to affected areas, potentially saving lives and reducing response times.

These diverse applications necessitate tailored designs and operational strategies.

Applications and Future Trends

VTOL (Vertical Take-Off and Landing) vehicles are poised to revolutionize transportation, particularly in urban environments. Their unique ability to take off and land vertically, unlike traditional aircraft, opens up a wide array of applications beyond the current scope of air travel. This section explores the potential applications, future evolution, and societal impacts of this emerging technology.The future of VTOL technology is marked by a convergence of advancements in propulsion, aerodynamics, and autonomous systems.

This integration promises increased efficiency, safety, and accessibility for a wider range of users. Furthermore, the development of autonomous systems is paving the way for a future where VTOL vehicles can operate with minimal or no human intervention.

Potential Applications

VTOL vehicles hold the potential to transform various sectors. Their ability to navigate congested urban areas and access remote locations offers numerous practical applications.

- Urban Air Mobility (UAM): VTOL vehicles can facilitate efficient and convenient transportation within cities, reducing traffic congestion and travel times. Examples include personal transportation for commuting, delivery services, and emergency medical services. Imagine a future where urgent medical supplies are delivered in minutes instead of hours.

- Cargo Delivery: The ability to take off and land vertically enables VTOL vehicles to access remote or congested areas for faster and more efficient cargo delivery. This is especially beneficial for last-mile delivery services and remote areas requiring rapid resupply.

- Tourism and Recreation: VTOL vehicles can offer unique and exciting tourism opportunities, allowing for quick access to scenic locations or facilitating aerial tours of urban landscapes. Consider breathtaking aerial views of a city or a tour over a national park.

- Agriculture and Surveying: VTOL vehicles can be equipped for precision agriculture and aerial surveying tasks, providing farmers with real-time data and enabling more efficient and targeted agricultural practices. This can involve surveying vast tracts of land for crop health assessment.

Future of VTOL Technology

The future of VTOL technology hinges on several key advancements. The integration of more efficient propulsion systems, improved aerodynamic designs, and sophisticated autonomous navigation capabilities are critical for widespread adoption.

- Increased Efficiency: Continued research and development are focused on optimizing propulsion systems, aerodynamic designs, and overall vehicle efficiency to reduce operating costs and environmental impact. This will involve a focus on reducing fuel consumption and noise pollution.

- Enhanced Safety: Safety is paramount in the development of VTOL vehicles. Advanced sensor systems, robust control algorithms, and improved flight control systems are crucial for ensuring safe operation in various atmospheric conditions and traffic scenarios.

- Autonomous Operation: Autonomous VTOL systems hold immense potential for streamlining operations and increasing efficiency. The development of sophisticated algorithms and sensor fusion techniques will allow for greater automation and reduced human intervention.

Urban Air Mobility Challenges and Opportunities

Urban air mobility presents both challenges and opportunities. Addressing issues related to airspace management, safety regulations, and infrastructure development is essential for realizing the full potential of VTOL vehicles.

- Airspace Management: Developing efficient airspace management systems that integrate VTOL traffic with traditional aircraft traffic is a significant challenge. This will involve the implementation of advanced air traffic control systems to regulate the flow of VTOL vehicles in urban airspace.

- Infrastructure Development: The development of dedicated VTOL landing and take-off (VTOL) infrastructure is necessary to support the expansion of UAM. This includes constructing suitable landing pads and charging stations for VTOL vehicles.

- Regulatory Framework: Establishing clear and comprehensive regulations for VTOL operations is crucial for ensuring safety and preventing accidents. This involves collaboration between aviation authorities and technology developers.

Societal Impacts of VTOL Vehicles

VTOL vehicles have the potential to significantly impact various aspects of society. These vehicles can alter urban landscapes, create new job opportunities, and reshape transportation patterns.

- Transportation Revolution: VTOL vehicles can revolutionize transportation, reducing traffic congestion, improving accessibility, and providing more efficient travel options.

- Economic Growth: The development and implementation of VTOL technology can generate significant economic growth through job creation in manufacturing, operations, and maintenance.

- Environmental Impact: The environmental impact of VTOL vehicles depends on the specific propulsion systems used. Sustainable propulsion technologies will be crucial for minimizing environmental impact.

Development of Autonomous VTOL Systems

The development of autonomous VTOL systems is rapidly advancing. The integration of advanced sensors, robust algorithms, and reliable communication systems are key factors in this progress.

- Advanced Sensors: Advanced sensors, including LiDAR, radar, and cameras, provide crucial data for autonomous navigation and obstacle avoidance in complex urban environments. The combination of these sensors provides a comprehensive understanding of the vehicle’s surroundings.

- Robust Algorithms: Robust algorithms play a vital role in enabling autonomous flight. These algorithms allow the VTOL vehicle to make real-time decisions based on sensor data and navigate safely through dynamic environments.

- Reliable Communication Systems: Reliable communication systems are essential for maintaining communication between the VTOL vehicle and ground control, allowing for efficient monitoring and control of the vehicle’s operations.

VTOL Vehicle Safety

VTOL (Vertical Take-off and Landing) vehicles present unique safety challenges compared to traditional aircraft. These challenges stem from the complex interplay of vertical lift, propulsion systems, and potentially unpredictable flight dynamics. Thorough safety measures and stringent operational protocols are paramount to mitigating these risks and ensuring the safe operation of VTOL aircraft.

Safety Measures Employed in VTOL Vehicles

Safety in VTOL vehicles is a multifaceted endeavor. It involves rigorous design considerations, extensive testing protocols, and proactive maintenance procedures. Redundant safety systems are crucial to mitigate potential failures, and the systems are often designed with fail-safe mechanisms. Pilot training programs are also critical to prepare operators for the specific demands of VTOL operations, including emergency procedures.

Safety Protocols for VTOL Operations

Strict adherence to safety protocols is essential for VTOL operations. These protocols encompass pre-flight inspections, weather checks, and detailed flight plans. Ground crew procedures for VTOL vehicles must be rigorously standardized, and emergency response protocols must be readily available and practiced. Communication protocols between ground control and the pilot are critical to ensure seamless and safe operations.

Safety Considerations for Different Types of VTOL Vehicles

Safety considerations differ based on the specific VTOL vehicle type. Electric VTOL aircraft, for example, often prioritize battery safety and thermal management to prevent overheating and fires. Hybrid or ducted-fan VTOL designs might have different safety requirements related to the interaction of the rotors and the propellers or fans. The varying weights, flight profiles, and propulsion methods of different VTOL vehicles necessitate tailored safety procedures.

VTOL vehicles are getting a lot of attention, and rightly so. Optimizing their flight characteristics, like many other complex systems, involves careful performance tuning. This process, crucial for maximizing efficiency and handling, is a key factor in the continued development of VTOL vehicles. Performance tuning principles are being applied to improve aspects like vertical take-off and landing, speed, and range.

Ultimately, better performance tuning translates to better VTOL vehicle capabilities.

Risk Factors and Mitigation Strategies for VTOL Vehicles

Several risk factors contribute to potential safety concerns in VTOL vehicles. These include, but are not limited to, component failure, adverse weather conditions, and pilot error. Mitigation strategies encompass robust design practices, advanced sensor systems for real-time monitoring, and comprehensive training programs for pilots and ground crews. For example, redundant control systems can mitigate the risk of a single point of failure.

Safety Regulations and Standards

| Regulation/Standard | Description | Impact on VTOL Safety |

|---|---|---|

| FAA (Federal Aviation Administration) regulations | Comprehensive set of rules and guidelines for the certification and operation of aircraft in the US. | Establishes safety standards for VTOL design, testing, and operation. |

| EASA (European Union Aviation Safety Agency) regulations | European counterpart to FAA regulations. | Provides comparable safety standards for VTOL vehicles operating in the European Union. |

| ISO (International Organization for Standardization) standards | International standards for various aspects of engineering, including design and manufacturing. | Provides guidelines for consistent and quality standards in VTOL production and maintenance. |

| Specific VTOL manufacturer standards | Additional standards or guidelines implemented by manufacturers to enhance the safety of their particular VTOL models. | Ensures specific design, maintenance, and operational standards unique to the vehicle model. |

Safety in VTOL vehicles is a continual process of improvement, adapting to new technologies and evolving operational needs.

VTOL Manufacturing and Supply Chain

The production of Vertical Take-Off and Landing (VTOL) aircraft presents unique challenges compared to traditional fixed-wing aircraft. The intricate interplay of multiple components, specialized materials, and advanced technologies necessitates a robust and adaptable manufacturing and supply chain. This intricate network must accommodate the rapid pace of technological advancement in the field, and ensure the timely delivery of high-quality components.The complexities of VTOL vehicle manufacturing extend beyond the assembly process, encompassing the entire supply chain.

From the raw materials to the final delivery of the aircraft, every step demands careful coordination and robust logistics. This includes not only the acquisition of components but also their integration into the final product, which must be rigorously tested to meet stringent safety and performance standards.

Manufacturing Processes for VTOL Vehicles

VTOL vehicle manufacturing often involves a combination of traditional and advanced manufacturing techniques. This includes machining, 3D printing, and composite material fabrication. Precision machining is critical for ensuring the accuracy and functionality of critical components like propellers and landing gear. 3D printing, with its ability to create complex geometries, can be employed for producing lightweight yet strong parts.

Composite materials, known for their strength-to-weight ratio, are extensively used in the construction of airframes and other components. These techniques, often employed in tandem, contribute to the creation of lightweight, high-performance vehicles.

Complexities of the VTOL Supply Chain

The supply chain for VTOL production is inherently intricate. The need for specialized components, such as advanced electric motors, high-capacity batteries, and sophisticated flight control systems, necessitates a global network of suppliers. This network must ensure timely delivery, quality control, and responsiveness to evolving technological demands. The interdependence of numerous suppliers and their ability to adapt to rapid technological changes are significant factors.

Need for Specialized Manufacturing Facilities

The production of VTOL vehicles demands specialized facilities equipped to handle the intricate manufacturing processes and rigorous quality control measures. These facilities should possess advanced equipment and skilled personnel capable of handling the unique challenges presented by these complex systems. Facilities must be equipped to handle the sensitive nature of components and the complex assembly processes.

Roles of Stakeholders in the VTOL Supply Chain

The VTOL supply chain involves a diverse array of stakeholders. These include original equipment manufacturers (OEMs), component suppliers, logistics providers, research and development organizations, and regulatory bodies. Each stakeholder plays a crucial role in the success of the VTOL production process. OEMs are responsible for the overall design and integration of components. Component suppliers must meet exacting standards of quality and delivery.

Logistics providers ensure the timely and secure movement of parts. Regulatory bodies ensure compliance with safety and environmental standards.

Potential Disruptions to the VTOL Supply Chain, VTOL vehicles

Several potential disruptions could affect the VTOL supply chain. These include geopolitical instability, natural disasters, supply shortages of critical materials, and unexpected technological hurdles. Geopolitical instability can disrupt the flow of materials or components from certain regions. Natural disasters can lead to factory closures and delays. Supply shortages of materials, such as rare earth minerals used in certain components, could create bottlenecks.

Vertical take-off and landing (VTOL) vehicles are intriguing, promising faster and more efficient transportation. Their potential for integration with car-to-home power systems, like car-to-home power systems , could revolutionize energy storage and distribution, ultimately paving the way for a more sustainable future for VTOL vehicle technology.

Unforeseen technological hurdles in the development of key components could significantly impact production schedules. The diversification of the supply chain and the establishment of backup suppliers are crucial in mitigating these risks.

VTOL Vehicle Economics

The economic viability of Vertical Take-Off and Landing (VTOL) vehicles is a critical factor in their future adoption. Understanding the development, production, and operational costs, alongside potential market size and applications, is crucial for assessing the long-term financial feasibility of this emerging technology. This section examines these factors in detail, providing insights into the cost-effectiveness of different VTOL propulsion systems and applications.The economic landscape of VTOL vehicles is complex, involving significant upfront investment in research, development, and manufacturing infrastructure.

Factors like material costs, manufacturing processes, and regulatory approvals all contribute to the overall expense. The economic feasibility of different VTOL designs hinges on balancing these costs with the potential revenue streams from various applications.

Cost Factors in VTOL Vehicle Development and Production

Development and production costs of VTOL vehicles are substantial and span numerous areas. Raw material costs, particularly for advanced materials like composites and lightweight metals, are a significant factor. Manufacturing processes, often complex and requiring specialized equipment, further inflate production costs. The complexity of integrating multiple systems, including propulsion, flight control, and power management, also increases the overall cost.

Finally, regulatory approvals and certifications add significant bureaucratic and financial burdens.

Cost-Effectiveness of Different VTOL Propulsion Systems

Different VTOL propulsion systems have varying economic implications. Electric vertical take-off and landing (eVTOL) systems, for instance, may exhibit lower operational costs due to reduced fuel consumption and maintenance requirements. However, the high initial cost of batteries and charging infrastructure can offset these advantages. Conversely, hybrid systems might offer a balance between the cost of electric and traditional fuel-based systems, but the added complexity in design and maintenance may impact cost-effectiveness.

The optimal choice depends on the specific application and operational conditions.

Potential Market Size for VTOL Vehicles

The potential market for VTOL vehicles is vast and diverse. Early market adoption will likely focus on urban air mobility (UAM) applications, with potential for high-frequency, short-distance travel within congested urban centers. This market is projected to grow significantly, driven by increasing urban population density, traffic congestion, and a desire for faster, more convenient transportation solutions. Other potential markets include cargo delivery, emergency services, and even tourism.

Economic Viability of Different VTOL Applications

The economic viability of VTOL applications varies considerably. The high initial cost of VTOL vehicles may make early adoption challenging for personal use, though commercial and cargo applications may prove more economically viable in the near term. UAM applications, particularly in high-density urban areas, are likely to see more rapid development and market penetration due to the significant time and cost savings compared to traditional ground transportation.

The potential for increased efficiency and reduced congestion could make UAM applications highly attractive for investors and consumers alike.

Conclusion

In conclusion, VTOL vehicles represent a significant leap forward in aviation technology, offering a potential paradigm shift in how we navigate our cities and beyond. Their multifaceted nature, encompassing various propulsion systems and design considerations, presents both challenges and opportunities for future development. As the technology matures, we can expect to see a growing number of applications, from personal transportation to cargo delivery, shaping the urban landscape and the global transportation network.

Question & Answer Hub

What are the primary challenges in VTOL vehicle manufacturing?

Integrating multiple complex systems, such as propulsion, control, and safety mechanisms, into a compact and lightweight airframe presents significant manufacturing challenges. Specialized facilities and skilled labor are essential for efficient production.

What are some potential safety concerns with VTOL vehicles?

Safety is paramount. Issues include maintaining stability during takeoff and landing, managing unexpected mechanical failures, and ensuring passenger safety during operation. Strict regulations and rigorous testing are crucial.

How does the cost of VTOL vehicles compare to traditional aircraft?

The cost of VTOL vehicle development and production is currently high due to the complex engineering and specialized components involved. However, economies of scale and technological advancements are expected to drive down costs over time, making them more accessible.

What are the environmental impacts of different VTOL propulsion systems?

Electric VTOL vehicles generally have a smaller environmental footprint than those with jet or hybrid propulsion systems. However, the environmental impact also depends on the source of energy used to power the electric motors.