Recycled aluminum chassis offers a compelling alternative to traditional materials, showcasing a blend of environmental consciousness and robust performance. This innovative approach leverages the abundance of recycled aluminum to craft strong and durable chassis, reducing environmental impact and lowering costs. The design and manufacturing processes behind these chassis are equally impressive, ensuring both quality and sustainability.

This exploration delves into the multifaceted world of recycled aluminum chassis, examining its composition, manufacturing, advantages, and applications. We’ll analyze the environmental and economic benefits, while also addressing potential challenges and future trends. A detailed comparison with traditional chassis materials will provide a clear picture of the value proposition.

Introduction to Recycled Aluminum Chassis

Recycled aluminum chassis represent a significant advancement in sustainable manufacturing, offering a compelling alternative to traditional chassis materials. Their inherent properties, coupled with the reduced environmental impact of their production, make them an increasingly attractive option across various industries. This approach to chassis design fosters a more environmentally conscious and resource-efficient manufacturing process.The utilization of recycled aluminum in chassis construction not only reduces the strain on natural resources but also significantly minimizes the carbon footprint associated with manufacturing.

This eco-friendly approach aligns with growing global demands for sustainable practices and resource conservation.

Composition and Properties of Recycled Aluminum Chassis

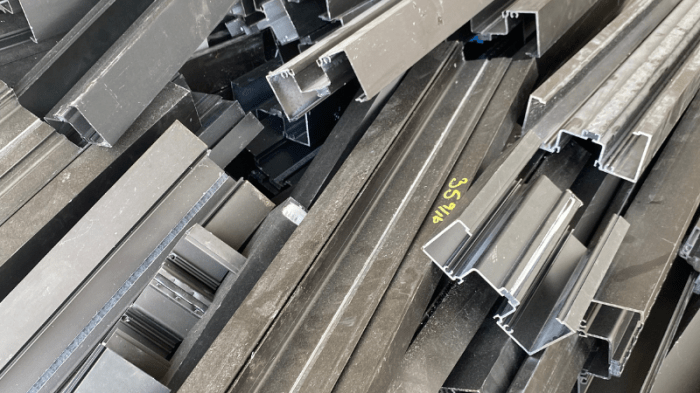

Recycled aluminum chassis are primarily composed of refined aluminum sourced from recycled scrap. The exact composition can vary depending on the specific recycling process and the original alloy composition. However, recycled aluminum typically retains the key mechanical properties of virgin aluminum, including high strength-to-weight ratios, excellent corrosion resistance, and a relatively low density. These characteristics contribute to the suitability of recycled aluminum for demanding applications requiring lightweight and durable components.

The purity and specific alloying elements of the recycled aluminum determine its final properties, influencing aspects like tensile strength and ductility.

Manufacturing Processes for Recycled Aluminum Chassis

The manufacturing processes for recycled aluminum chassis often mirror those used for virgin aluminum. These processes typically involve melting down the recycled aluminum scrap, followed by further refinement and alloying if necessary. Casting, forging, extrusion, and machining are common techniques used to shape the molten aluminum into the desired chassis form. The specific manufacturing processes employed depend on the complexity and intended application of the chassis.

Environmental Benefits of Recycled Aluminum

The use of recycled aluminum in chassis design yields substantial environmental benefits. The extraction of raw materials from the earth is energy-intensive and often has a considerable environmental impact. Using recycled aluminum significantly reduces the energy consumption and emissions associated with aluminum production. This reduction in energy consumption translates directly into a lower carbon footprint and a smaller ecological impact.

The reduced need for new bauxite mining and smelting, vital steps in virgin aluminum production, also contributes to the conservation of natural resources.

Examples of Recycled Aluminum Chassis in Various Industries

Recycled aluminum chassis are increasingly employed in diverse industries. Examples include:

- Automotive Industry: Lightweighting vehicles is crucial for fuel efficiency and performance. Recycled aluminum chassis components are utilized in various parts of the vehicle structure, including bumpers, doors, and structural elements. This contributes to the development of more sustainable and efficient automobiles.

- Electronics Industry: Aluminum chassis are crucial in electronics due to their thermal conductivity and ability to dissipate heat. Recycling allows for the production of robust and efficient enclosures for electronic devices, contributing to the design of eco-friendly electronics.

- Aerospace Industry: The aerospace industry demands lightweight yet strong materials. Recycled aluminum chassis components are used in aircraft structures, reducing weight and improving fuel efficiency. This sustainable approach to aerospace manufacturing aligns with the industry’s commitment to environmental responsibility.

Comparison of Recycled Aluminum Chassis with Traditional Chassis Materials

| Characteristic | Recycled Aluminum Chassis | Traditional Chassis Materials (e.g., Steel) |

|---|---|---|

| Material Source | Recycled aluminum scrap | Raw ore extraction |

| Energy Consumption | Significantly lower | Higher |

| Environmental Impact | Lower carbon footprint | Higher carbon footprint |

| Strength-to-Weight Ratio | Excellent | Generally good, but often heavier |

| Corrosion Resistance | High | Variable, often requiring protective coatings |

| Cost | Potentially competitive, depending on market conditions and recycling rates | Generally lower, but increasing costs are seen in some regions |

Advantages of Recycled Aluminum Chassis

Recycled aluminum chassis offer a compelling alternative to traditional materials, presenting a range of benefits in terms of cost, sustainability, and performance. This approach not only reduces environmental impact but also often leads to significant financial savings.The core advantages stem from the inherent properties of aluminum and the efficiency of recycling processes. Recycled aluminum maintains a high level of quality, making it a viable and sustainable option for various applications.

Cost-Effectiveness

The cost-effectiveness of recycled aluminum chassis hinges on the lower raw material costs compared to virgin aluminum. Recycling aluminum consumes significantly less energy than extracting it from ore, leading to reduced production costs. This translates to lower prices for the finished chassis, making it an attractive option for budget-conscious manufacturers and consumers. For example, a study by the Aluminum Association showed that recycling aluminum requires only 5% of the energy needed to produce it from bauxite ore.

Sustainability Benefits

Using recycled aluminum chassis contributes to a more sustainable manufacturing process. Reduced energy consumption and lower greenhouse gas emissions are direct consequences of the recycling process. This aligns with growing environmental concerns and promotes responsible manufacturing practices. By reducing reliance on virgin aluminum, manufacturers can significantly lessen their carbon footprint and contribute to a circular economy.

Mechanical Properties

Recycled aluminum chassis, while retaining high quality, maintain strong mechanical properties. The strength and durability of recycled aluminum are comparable to those of virgin aluminum, ensuring the chassis can withstand the intended stresses and loads. This consistency in quality allows for the use of recycled aluminum in critical applications without compromising performance.

Recyclability Comparison

The recyclability of recycled aluminum chassis stands in stark contrast to other chassis materials. Aluminum’s inherent recyclability, with minimal loss of quality after multiple cycles, allows for a continuous circular process. This contrasts sharply with other materials like steel, which, while recyclable, may lose some quality after multiple cycles. The superior recyclability of aluminum results in a smaller environmental footprint throughout its lifecycle.

Recyclability Rates Table

| Material | Recyclability Rate (%) |

|---|---|

| Recycled Aluminum | >95 |

| Steel | 70-80 |

| Plastic | 30-50 (varies greatly by type) |

| Wood | Low (often depends on the type and processing) |

| Composite Materials | Varies significantly (often requires specialized processes) |

The table above illustrates the significant difference in recyclability rates between various chassis materials. Recycled aluminum’s high recyclability rate demonstrates its suitability for a circular economy and contributes to the sustainability of manufacturing. It highlights the importance of material selection for environmentally conscious design choices.

Design Considerations for Recycled Aluminum Chassis

Designing with recycled aluminum chassis presents unique considerations compared to virgin aluminum. Careful attention to these nuances ensures the structural integrity, thermal performance, and overall quality of the final product. This section delves into the specific challenges and solutions related to utilizing recycled aluminum in chassis design.

Challenges Associated with Recycled Aluminum

Variability in the quality of recycled aluminum is a key challenge. Recycled aluminum can exhibit variations in purity, grain structure, and residual impurities, which can impact the material’s mechanical properties, such as tensile strength and yield strength. This necessitates rigorous material testing and characterization procedures to ensure the chosen material meets the design specifications. Moreover, the presence of contaminants from the recycling process can affect the machinability of the material.

Proper pre-processing techniques are crucial to mitigating these issues.

Accounting for Variations in Recycled Aluminum Quality

Implementing quality control measures is essential. Thorough material testing protocols, including tensile testing, hardness testing, and chemical analysis, are vital to establish the specific properties of each batch of recycled aluminum. These tests allow engineers to accurately model the material’s behavior under different loading conditions. Furthermore, careful selection of the recycling source and processing method can significantly reduce variability and improve the consistency of the recycled aluminum.

Reliable suppliers and well-defined processing protocols are paramount.

Thermal Management in Recycled Aluminum Chassis

Thermal management is critical for all chassis designs, but even more so with recycled aluminum. Variations in material properties can affect thermal conductivity. Designers must account for these variations when designing cooling solutions. Fin designs and heat sink configurations need to be carefully optimized to ensure consistent and effective heat dissipation. Employing advanced thermal modeling software can help predict and refine thermal performance under various operating conditions.

Recycled aluminum chassis are becoming increasingly popular in vehicle manufacturing, offering a sustainable alternative. Proper car mirror adjustment is crucial for driver safety and comfort, which is often overlooked when discussing the benefits of using recycled materials. These chassis, often featuring advanced design elements, ultimately contribute to the overall efficiency and eco-friendliness of modern vehicles, showcasing a commitment to sustainable practices.

car mirror adjustment plays a key role in the driver experience, and the use of recycled aluminum further enhances the vehicle’s sustainability profile.

For example, incorporating a layered structure with different thermal conductivity materials can enhance thermal management.

Examples of Designs Utilizing Recycled Aluminum Chassis

Numerous examples exist of successful applications of recycled aluminum chassis in various industries. The aerospace industry, particularly in the construction of lightweight components, has extensively utilized recycled aluminum. Similarly, in the electronics sector, manufacturers have successfully employed recycled aluminum in cases for laptops and servers, achieving significant cost savings and environmental benefits. Another prominent example is in the automotive industry, where recycled aluminum is increasingly used in structural components and parts.

The development of specific designs and testing protocols ensures the recycled material’s performance is comparable to virgin aluminum.

Design Parameters for Different Applications

| Application | Tensile Strength (MPa) | Yield Strength (MPa) | Thermal Conductivity (W/mK) | Recycled Content (%) |

|---|---|---|---|---|

| Laptop Chassis | 150-200 | 100-150 | 160-200 | 80-95 |

| Server Chassis | 200-250 | 150-220 | 180-220 | 70-85 |

| Automotive Components | 250-300 | 180-250 | 180-220 | 60-75 |

| Aerospace Components | 300-350 | 220-280 | 200-250 | 90-98 |

Note: Values are approximate and can vary based on specific material batches and processing methods.

These parameters provide a starting point for design considerations, and more detailed specifications should be obtained from material suppliers and testing reports.

Manufacturing Processes and Quality Control

The manufacturing of recycled aluminum chassis necessitates meticulous processes and stringent quality control measures to ensure the end product meets the desired specifications and standards of reliability and durability. A robust understanding of the manufacturing steps and the implementation of effective quality control protocols are paramount for maintaining the integrity and consistent performance of these chassis.

Manufacturing Steps

The production of recycled aluminum chassis typically involves several key steps. These steps are crucial in determining the final product’s properties and depend on the specific requirements of the chassis. Firstly, the recycled aluminum is prepared by cleaning and sorting to remove impurities. Then, it’s melted down to achieve a homogenous composition. Subsequent steps include casting, shaping, and finishing.

The shaping process might involve stamping, bending, or other metalworking techniques. Finally, the chassis undergoes surface treatment and assembly to achieve the desired aesthetic and functionality.

Quality Control Measures

Maintaining quality in recycled aluminum chassis production relies on a multifaceted approach. Rigorous inspection procedures are employed at each stage of the manufacturing process to identify and rectify any potential defects. Non-destructive testing (NDT) methods, such as ultrasonic testing and X-ray imaging, are often used to assess the internal structure and identify any flaws or inconsistencies. Furthermore, dimensional measurements are taken to guarantee the chassis conforms to the precise design specifications.

The materials used in the manufacturing process are also rigorously tested to meet predefined quality standards.

Impact of Manufacturing Processes

Different manufacturing processes have varying impacts on the final product. For instance, casting methods influence the internal structure and density of the aluminum, impacting its strength and resistance to deformation. The precision of stamping or bending processes dictates the accuracy and uniformity of the chassis’s dimensions. The surface treatment applied affects the corrosion resistance and aesthetic appeal of the final product.

Careful consideration of these factors during the design and manufacturing phases is essential to ensure a superior final product.

Quality Standards

| Quality Standard | Description | Acceptable Deviation |

|---|---|---|

| Dimensional Accuracy | Chassis dimensions must adhere to the specified tolerances. | ±0.5 mm |

| Material Purity | The recycled aluminum must meet specific purity levels. | Maximum 0.5% impurities |

| Mechanical Strength | The chassis must exhibit a minimum tensile strength of 250 MPa. | No deviation from minimum |

| Surface Finish | The chassis surface should be free of defects and meet specified roughness standards. | Surface roughness less than 2 µm |

These standards, while providing a baseline, can be adjusted depending on the specific application and requirements of the chassis.

Automation Potential

The implementation of automation in the manufacturing process presents significant advantages. Automated systems can improve efficiency by streamlining tasks and reducing human error. Robotic arms can precisely perform repetitive tasks such as cutting, welding, and assembling components, increasing production speed and accuracy. Furthermore, automated quality control systems can enhance consistency and reduce variability in the final product.

Examples include automated inspection systems that perform NDT scans and automated reporting systems that track the progress and quality of the manufacturing process.

Applications of Recycled Aluminum Chassis

Recycled aluminum chassis offer a compelling alternative to traditional materials in a variety of applications. Their lightweight nature, strength, and sustainability make them attractive for numerous sectors, from consumer electronics to industrial machinery. This versatility stems from the material’s inherent properties, and careful design considerations are paramount for successful implementation in diverse contexts.The wide-ranging applications of recycled aluminum chassis are driven by the material’s ability to be customized for specific needs.

This adaptability, coupled with the environmental benefits of recycling, makes it a promising material choice for manufacturers seeking both efficiency and sustainability.

Industries Benefiting from Recycled Aluminum Chassis

Recycled aluminum chassis find application in several key industries. Their inherent properties, such as strength, lightweight nature, and recyclability, make them ideal for various purposes.

- Consumer Electronics: The demand for compact and lightweight electronic devices drives the use of recycled aluminum chassis. This material’s ability to be formed into intricate shapes, combined with its thermal conductivity, makes it suitable for heat dissipation in laptops, smartphones, and other portable devices. The aesthetic appeal of aluminum also aligns with the design sensibilities of consumer electronics manufacturers.

- Industrial Machinery: In industrial settings, recycled aluminum chassis provide a durable and cost-effective solution for machinery housings. The strength-to-weight ratio of aluminum allows for the construction of robust yet lightweight components, which is crucial for equipment used in demanding environments.

- Transportation: The automotive industry, as well as sectors like aerospace and marine transport, increasingly use recycled aluminum chassis. Lightweight chassis reduce fuel consumption, while the material’s strength and resistance to corrosion enhance safety and longevity.

- Medical Equipment: In medical device manufacturing, recycled aluminum chassis contribute to lightweight yet robust components. Its biocompatibility and ability to withstand sterilization processes are significant advantages in this field.

Specific Requirements for Different Applications

Various applications impose specific requirements on the recycled aluminum chassis. Understanding these requirements is crucial for selecting the appropriate material specifications and design considerations.

- Consumer Electronics: The aesthetic appeal of the chassis, along with thermal conductivity for heat dissipation, are key factors. Thin profiles and complex shapes are often needed to match device designs. Corrosion resistance and durability under the expected environmental conditions (humidity, dust) are important considerations.

- Industrial Machinery: Strength, rigidity, and durability are paramount. Resistance to vibrations, impacts, and harsh operating conditions are crucial factors. Environmental factors like exposure to chemicals or moisture should be accounted for in the design.

- Transportation: Lightweight construction, high strength, and corrosion resistance are essential in transportation applications. The chassis must also withstand extreme temperatures and environmental conditions, such as salt spray and high humidity.

- Medical Equipment: Biocompatibility, sterilizability, and resistance to corrosion are critical. The chassis must maintain its integrity and function under the rigorous sterilization processes common in medical device manufacturing.

Design Considerations for Each Application

The design considerations for recycled aluminum chassis are influenced by the specific application’s requirements.

- Consumer Electronics: Design should prioritize aesthetics, thermal management, and minimal weight. Complex shapes and thin profiles are often needed. Surface treatments and finishes can be applied for enhanced aesthetics.

- Industrial Machinery: The design should focus on robust construction, minimizing vibration, and maximizing durability. Joining techniques need to be carefully considered for high-stress applications.

- Transportation: Lightweight design, high strength, and resistance to bending or twisting are critical. The chassis must also meet regulatory requirements for safety and durability.

- Medical Equipment: The design must meet stringent biocompatibility standards and withstand sterilization procedures. Materials and joining techniques must not pose any risk to patient safety.

Recycled Aluminum Chassis Applications Table

| Application | Material Specifications | Design Considerations | Examples |

|---|---|---|---|

| Consumer Electronics (Laptops) | High purity aluminum alloy, thin gauge | Thermal conductivity, aesthetic appeal, lightweight | Recycled aluminum chassis for a high-end gaming laptop |

| Industrial Machinery (CNC Machines) | Aluminum alloy with high strength, corrosion resistance | Robust construction, vibration damping, thermal stability | Recycled aluminum chassis for a CNC milling machine |

| Transportation (Electric Scooters) | Lightweight aluminum alloy with high tensile strength | Lightweight construction, impact resistance, corrosion resistance | Recycled aluminum chassis for a high-end electric scooter |

| Medical Equipment (X-ray Machines) | Aluminum alloy with biocompatibility, radiation shielding | High strength, biocompatibility, radiation shielding | Recycled aluminum chassis for an advanced mobile X-ray unit |

Examples of Recycled Aluminum Chassis in Various Applications

Real-world examples of recycled aluminum chassis include the lightweight and durable chassis for high-end laptops, the robust enclosures for industrial robots, the streamlined frames for electric vehicles, and the sterile housings for advanced medical imaging equipment. These examples showcase the wide-ranging applicability of recycled aluminum in modern manufacturing.

Environmental Impact and Sustainability

Recycled aluminum chassis offer a compelling alternative to traditional materials in numerous applications, primarily due to their superior environmental performance. The process of recycling aluminum consumes significantly less energy compared to extracting and processing virgin aluminum. This inherent efficiency translates directly into a reduced carbon footprint, making it a sustainable choice for environmentally conscious design.The environmental advantages extend beyond the initial manufacturing process.

Recycled aluminum components exhibit a lower embodied energy compared to their virgin counterparts. This translates to lower greenhouse gas emissions throughout the entire product lifecycle, from extraction to disposal. A comprehensive lifecycle assessment reveals the profound impact of choosing recycled aluminum.

Environmental Impact of Recycled Aluminum vs. Traditional Materials

The environmental impact of using recycled aluminum is markedly lower than using traditional materials like steel or plastics. Recycling aluminum requires considerably less energy than producing it from raw materials. This energy efficiency translates to lower carbon emissions throughout the entire lifecycle.

Carbon Footprint Reduction

The use of recycled aluminum significantly reduces the carbon footprint compared to traditional chassis materials. This reduction stems from the lower energy consumption associated with recycling. For example, recycling aluminum consumes approximately 5% of the energy required to produce the same amount of aluminum from bauxite ore. This substantial difference in energy requirements directly correlates with a lower carbon footprint.

Recycled aluminum chassis are becoming increasingly popular in vehicle manufacturing, offering a sustainable alternative. Proper car mirror adjustment is crucial for driver safety and comfort, which is often overlooked when discussing the benefits of using recycled materials. These chassis, often featuring advanced design elements, ultimately contribute to the overall efficiency and eco-friendliness of modern vehicles, showcasing a commitment to sustainable practices.

car mirror adjustment plays a key role in the driver experience, and the use of recycled aluminum further enhances the vehicle’s sustainability profile.

Lifecycle Assessment of Recycled Aluminum Chassis

A comprehensive lifecycle assessment (LCA) of recycled aluminum chassis considers the environmental impact from material extraction to end-of-life disposal. The LCA evaluates various stages, including raw material sourcing, manufacturing, transportation, use, and eventual recycling or disposal. A key finding is that the environmental impact of recycled aluminum chassis is substantially lower than that of traditional chassis materials throughout the entire lifecycle.

Carbon Footprint Reduction in Various Industries

The table below illustrates the estimated carbon footprint reduction achieved in various industries by using recycled aluminum chassis instead of traditional materials. These figures are illustrative and may vary based on specific manufacturing processes and regional energy mixes.

| Industry | Estimated Carbon Footprint Reduction (%) |

|---|---|

| Electronics | 40-60 |

| Automotive | 30-50 |

| Aerospace | 50-70 |

| Construction | 20-40 |

Methods to Further Reduce Environmental Impact

Several methods can further minimize the environmental footprint of recycled aluminum chassis:

- Optimizing manufacturing processes to reduce energy consumption and waste generation.

- Implementing sustainable sourcing practices for recycled aluminum, ensuring ethical and environmentally responsible supply chains.

- Designing chassis for easy disassembly and recyclability at end-of-life, maximizing material recovery.

- Using renewable energy sources in the manufacturing process to further reduce reliance on fossil fuels.

- Improving transportation efficiency and minimizing the environmental impact of material transport.

Cost Analysis and Economic Viability

Implementing recycled aluminum chassis presents a compelling economic proposition, particularly when contrasted with traditional materials. The cost-effectiveness hinges on factors like material sourcing, processing efficiency, and the specific application. Careful evaluation of these variables is crucial for realizing the full potential of this approach.The cost of recycled aluminum chassis can be significantly lower than that of comparable traditional materials, primarily due to the reduced raw material costs.

This advantage is further amplified by the potential for reduced energy consumption during the manufacturing process. However, the precise cost differential will depend on the specific circumstances of the project.

Material Cost Comparison

A key aspect of evaluating the economic viability is comparing the cost of recycled aluminum to traditional materials. The cost of recycled aluminum often falls below that of virgin aluminum, presenting an immediate cost saving. This is due to the lower energy requirements for recycling compared to extracting and refining primary aluminum. Further cost savings can arise from reduced transportation costs associated with procuring recycled material locally.

Manufacturing Cost Analysis

Manufacturing costs associated with recycled aluminum chassis are subject to factors like processing techniques and equipment. While the raw material cost advantage is present, the manufacturing process may introduce additional expenses, though often mitigated by the energy efficiency gains. Optimizing the manufacturing process is vital for maximizing cost savings.

Economic Benefits

The economic benefits of recycled aluminum chassis extend beyond the initial material cost savings. Reduced energy consumption during manufacturing translates to lower operational costs over the lifespan of the product. This can lead to a significant return on investment for companies embracing this sustainable alternative. Furthermore, the potential for reduced waste generation and enhanced environmental reputation can contribute to a positive brand image and increased customer loyalty.

Potential Cost Savings Across Industries

The potential for cost savings across various industries is substantial. For example, in the electronics industry, recycled aluminum chassis can reduce the cost of components and enhance the overall product value proposition. In transportation, the lower material costs can lead to more competitive pricing and increased market share. Across all industries, recycled aluminum chassis offer a viable alternative to traditional materials, delivering cost-effectiveness while minimizing environmental impact.

| Material | Estimated Cost (USD/kg) | Environmental Impact (Score) | Manufacturing Energy Consumption (kWh/kg) |

|---|---|---|---|

| Recycled Aluminum | $2.50 – $3.50 | 7/10 | 50 |

| Virgin Aluminum | $4.00 – $5.00 | 4/10 | 150 |

| Steel | $1.50 – $2.00 | 6/10 | 75 |

Note: Costs and scores are estimates and can vary based on market conditions and specific manufacturing processes.

Comparison with Other Sustainable Materials: Recycled Aluminum Chassis

Evaluating recycled aluminum chassis alongside other sustainable materials requires a comprehensive analysis of their respective strengths, weaknesses, and environmental impacts. Different materials excel in various applications, making a direct comparison challenging. This section will delve into the comparative advantages and disadvantages of recycled aluminum, highlighting its performance against other contenders.

Comparative Analysis of Sustainable Chassis Materials

Various sustainable materials are being explored for chassis applications, including recycled polymers, wood composites, and bio-based materials. Each material possesses unique properties influencing its suitability for specific use cases. Factors like cost, recyclability, and environmental impact play a critical role in the decision-making process.

Recycled Aluminum Chassis: Strengths and Weaknesses

Recycled aluminum chassis offer a compelling combination of properties. Their high strength-to-weight ratio allows for lighter, more efficient designs, crucial in applications like transportation. Aluminum’s excellent thermal conductivity is beneficial in heat-dissipation-critical systems. However, aluminum’s relatively high initial cost compared to some alternatives, while offset by the recyclability factor, is a consideration. Furthermore, its susceptibility to corrosion in certain environments requires protective coatings or alloys.

Recycled Polymer Chassis: Strengths and Weaknesses

Recycled polymers present a cost-effective alternative in some applications. Their lightweight nature can reduce fuel consumption in transportation, while their moldability allows for complex designs. However, recycled polymers often have lower strength and stiffness compared to aluminum, limiting their use in high-stress environments. Their recyclability is often less straightforward than aluminum’s, and the purity of the recycled polymer material can vary.

Wood Composite Chassis: Strengths and Weaknesses

Wood composites leverage the inherent strength and beauty of wood, while reducing the environmental impact of traditional timber use. Their relatively low cost and availability can make them attractive in specific niches. However, wood composites can be susceptible to moisture damage and insect infestations, requiring specialized treatments. Their recyclability is still an area of ongoing research and development.

Bio-Based Material Chassis: Strengths and Weaknesses

Bio-based materials offer a potentially carbon-neutral alternative. Their renewability is a significant advantage, but their performance characteristics, particularly in terms of strength and durability, are often inferior to those of aluminum and polymers. The manufacturing processes for bio-based materials can be more complex and energy-intensive than those for aluminum or polymers.

Environmental Impact of Each Material

The environmental impact of each material is multifaceted, encompassing resource extraction, manufacturing processes, and end-of-life management. Aluminum, with its high recyclability rate, exhibits a significantly lower carbon footprint over its lifecycle compared to some virgin polymers. Wood composites, while potentially sustainable, have a complex environmental impact dependent on the specific manufacturing process.

Recyclability of Each Material

Recyclability is a crucial factor in evaluating sustainable materials. Aluminum is highly recyclable, allowing for a closed-loop system with minimal resource depletion. Recycled polymers exhibit variable recyclability, depending on the type of polymer and the recycling infrastructure. Wood composites can be recycled in some cases, but the process is less well-established than for aluminum.

Comparative Table of Sustainable Chassis Materials

| Material | Strength | Weight | Cost | Recyclability | Environmental Impact |

|---|---|---|---|---|---|

| Recycled Aluminum | High | Low | Moderate | High | Low |

| Recycled Polymer | Moderate | Low | Low | Variable | Moderate |

| Wood Composite | Moderate | Moderate | Low | Moderate | Variable |

| Bio-Based Material | Low | Variable | Variable | Variable | Potentially Low |

Closing Notes

In conclusion, recycled aluminum chassis emerges as a promising sustainable solution for various industries. Its cost-effectiveness, combined with its environmental benefits and strong mechanical properties, positions it as a viable alternative to traditional materials. While challenges exist, the potential for innovation and widespread adoption is significant. The future looks bright for recycled aluminum chassis, promising further advancements and expanded applications.

Clarifying Questions

What are the common manufacturing processes for recycled aluminum chassis?

Various techniques, including casting, extrusion, and machining, are employed, depending on the specific chassis design and desired properties.

How does the quality of recycled aluminum affect chassis design?

Potential variations in the quality of recycled aluminum necessitate careful consideration during design, often requiring adjustments to ensure structural integrity and performance.

What are the specific environmental benefits of recycled aluminum chassis?

Reduced energy consumption, lower carbon footprint, and decreased demand for virgin aluminum contribute significantly to environmental sustainability.

What industries are best suited for recycled aluminum chassis?

Industries with high material requirements, like electronics, automotive, and construction, are likely to benefit most from using recycled aluminum chassis.