OBD systems are crucial for modern vehicles, enabling diagnostics and troubleshooting. This guide delves into the intricacies of these systems, from their historical evolution to future trends. Understanding their components, functionalities, and security implications is essential for both vehicle owners and professionals.

This comprehensive exploration covers everything from basic OBD functionality to advanced applications in fleet management and performance optimization. We will also examine the evolving standards and regulations governing OBD systems across various regions, highlighting the significance of compliance.

Introduction to OBD Systems

On-board diagnostics (OBD) systems are crucial components in modern vehicles, enabling real-time monitoring and diagnosis of various vehicle systems. These systems use sensors and electronic control units (ECUs) to identify potential problems and alert the driver to potential malfunctions. This allows for proactive maintenance, preventing more significant and costly repairs down the line.The evolution of OBD systems reflects advancements in vehicle technology and the increasing complexity of engine management systems.

Early systems were rudimentary, while modern OBD systems offer sophisticated diagnostic capabilities and provide a wealth of information to technicians and drivers alike. The purpose of OBD is to enhance vehicle reliability, reduce emissions, and promote efficient vehicle maintenance.

Evolution of OBD Systems

OBD systems have undergone significant development across different vehicle generations. Early systems focused primarily on detecting and reporting engine malfunctions, whereas newer systems provide comprehensive diagnostics of various vehicle components. This evolution is directly tied to advancements in sensor technology, computing power, and diagnostic methodologies.

Fundamental Purpose and Functionalities

The fundamental purpose of OBD systems is to identify and diagnose potential issues within a vehicle’s systems. This is achieved through a network of sensors, electronic control units (ECUs), and diagnostic protocols. These functionalities encompass a wide range of tasks, from monitoring emissions levels to detecting mechanical issues in various components.

OBD systems are crucial for diagnosing car issues, but sometimes a more direct approach is needed. For instance, if you’re locked out, a window breaker tool, like the one found here , might be necessary. Ultimately, OBD systems are still the preferred method for preventative and ongoing maintenance.

Diagnostic Trouble Codes (DTCs) in OBD Systems

Diagnostic Trouble Codes (DTCs) are standardized codes that pinpoint specific malfunctions within the vehicle’s systems. Each DTC corresponds to a particular fault, and their identification allows for targeted repair and maintenance. DTCs are vital for accurate diagnostics, guiding technicians towards the root cause of the problem.

Comparison of OBD I and OBD II Systems

| Feature | OBD I | OBD II |

|---|---|---|

| Date of Introduction | Late 1980s | Early 1990s |

| Protocol | Mostly proprietary protocols | Standardized OBD-II protocol (e.g., SAE J1939) |

| Diagnostic Capabilities | Limited to engine diagnostics; often required specialized equipment for diagnostics | Expanded to encompass various vehicle systems (e.g., brakes, transmission); utilizes standardized diagnostic tools |

| Emission Standards Compliance | Limited emission standards coverage | Designed to comply with stricter emission regulations |

| Diagnostic Trouble Codes (DTCs) | Limited DTC range and less standardized | Extensive and standardized DTC database |

| Troubleshooting | More challenging and time-consuming due to less standardized diagnostics | Easier to diagnose and repair thanks to standardized codes and diagnostic tools |

OBD II represents a significant advancement over OBD I. The standardized protocol and comprehensive diagnostic capabilities have dramatically improved the efficiency and accuracy of vehicle diagnostics. This improvement translates to faster troubleshooting and lower repair costs for vehicle owners.

OBD System Components

OBD systems are crucial for diagnosing and maintaining vehicle performance. Understanding their components and functions is vital for technicians and enthusiasts alike. These systems provide a wealth of data, enabling precise identification of potential issues.The OBD system’s core components work together to collect, process, and transmit information about various vehicle parameters. This allows for comprehensive analysis of the vehicle’s operational status.

Accurate diagnosis is paramount, ensuring efficient repair and optimal vehicle performance.

Key Components of an OBD System

The OBD system is a complex network of interconnected components. These components play distinct roles in gathering, processing, and transmitting critical data. The interplay between these components is essential for the system’s effectiveness.

- Control Module (ECU): The central processing unit of the OBD system. It receives inputs from various sensors, processes this data according to predefined algorithms, and controls actuators. This is crucial for regulating engine operation, emissions, and other vehicle functions.

- Sensors: These components monitor various parameters like engine speed, air/fuel ratio, oxygen levels, and more. Sensors are critical in providing real-time data to the ECU for effective control and diagnostics.

- Actuators: These components receive commands from the ECU to adjust engine parameters, such as fuel injection or ignition timing. They are the effectors that translate the ECU’s decisions into physical actions within the vehicle.

- Communication Bus: The OBD system uses a communication bus to connect all components, enabling seamless data transfer. This enables real-time communication between the ECU, sensors, and actuators.

- Diagnostic Port (OBD-II Port): This is the physical interface where diagnostic tools connect to the vehicle’s OBD system. It’s a standardized connector, allowing various devices to access the system data.

Communication Protocols

Effective communication is essential for the OBD system’s functionality. Different protocols facilitate communication between various components.

- Controller Area Network (CAN): CAN is the predominant communication protocol in modern OBD systems. It allows for simultaneous communication between multiple components, ensuring efficient data transfer and reduced delays.

- J1939: J1939 is used in heavy-duty vehicles and some commercial applications. It focuses on the communication between the engine and various auxiliary systems. This is particularly useful for managing complex systems in trucks and buses.

Data Flow Diagram

The following diagram illustrates the flow of data within a typical OBD system.

[Diagram of data flow: A simplified representation depicting data flowing from sensors to the ECU, then to actuators, with communication bus connecting all components and the OBD-II port for external access. This diagram would use arrows to indicate the direction of data flow.]

Sensors and Actuators

The following table lists examples of sensors and actuators commonly integrated in modern OBD systems.

| Sensor | Actuator |

|---|---|

| Engine Speed Sensor | Fuel Injector |

| Oxygen Sensor | Throttle Position Sensor |

| Manifold Absolute Pressure (MAP) Sensor | Spark Plug |

| Crankshaft Position Sensor | Ignition Coil |

| Catalytic Converter Temperature Sensor | Air Intake Valve |

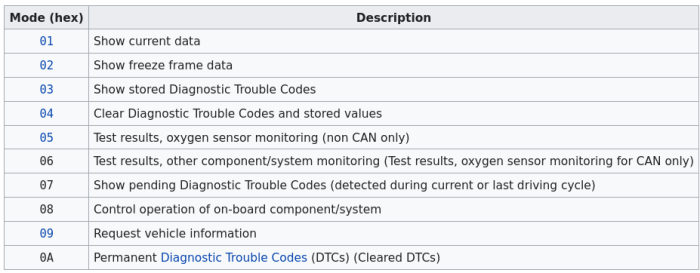

OBD Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are crucial elements of OBD systems. They are standardized codes that pinpoint specific malfunctions within a vehicle’s systems. Understanding DTCs allows technicians to effectively diagnose and repair issues, saving time and resources.DTCs provide a standardized language for communicating fault conditions across different makes and models of vehicles. This standardized format streamlines the diagnostic process, making it easier for technicians to identify the root cause of problems and implement appropriate repairs.

Meaning and Significance of DTCs

DTCs are alphanumeric codes that represent specific faults detected by the vehicle’s on-board diagnostic system. Each code corresponds to a particular component or system malfunction. The significance of DTCs lies in their ability to pinpoint the location and nature of the problem, enabling technicians to focus their troubleshooting efforts.

Categories of DTCs and their Implications

DTCs are categorized based on the system they relate to. Common categories include engine, transmission, emission control, and others. For example, a DTC related to the oxygen sensor indicates a potential issue with emissions. Understanding the system category provides valuable context for the nature of the fault.

Identification and Retrieval of DTCs

Diagnostic tools, such as scan tools and code readers, are used to identify and retrieve DTCs. These tools connect to the vehicle’s OBD-II port and access the stored diagnostic information. The specific process of retrieving DTCs varies slightly based on the tool, but generally involves initiating a scan and displaying the stored codes.

Common DTCs and Potential Causes

- P0300 – Random/Multiple Cylinder Misfire: This code indicates that the engine is misfiring in one or more cylinders without a consistent pattern. Potential causes include spark plug problems, fuel delivery issues, or a faulty ignition coil.

- P0420 – Catalyst System Efficiency Below Threshold: This code signifies a problem with the catalytic converter’s ability to reduce emissions. Potential causes might be a clogged converter, a malfunctioning oxygen sensor, or a leak in the exhaust system.

- P0171 – System Too Lean (Bank 1): This code suggests the engine is receiving too little fuel for the amount of air. Possible causes include a faulty mass airflow sensor (MAF), a vacuum leak, or a problem with the fuel injectors.

These are just a few examples, and the exact potential causes can vary based on the specific vehicle and its system configuration.

Interpreting and Resolving DTCs

A crucial step in resolving DTCs is consulting a repair manual or online resources. These resources often provide detailed explanations of each code, including possible causes and suggested troubleshooting steps. Furthermore, using diagnostic tools to identify related data and conditions can aid in diagnosing the problem.

OBD System Diagnostics

OBD systems provide a crucial avenue for diagnosing issues within a vehicle’s electronic control systems. Proper diagnostic procedures are essential for identifying the root cause of malfunctions and restoring optimal vehicle performance. This section details the steps involved in performing OBD diagnostics, the tools used, and how to interpret the data obtained.

Diagnostic Procedure Overview

A systematic approach to OBD diagnostics ensures efficient troubleshooting. The process generally involves several key steps: initial inspection, component isolation, and system verification. Each step builds upon the previous, allowing for a focused approach to finding the problem.

- Initial Inspection: Begin by visually inspecting the vehicle for any obvious signs of damage or malfunction. This preliminary assessment can narrow down the potential causes and guide subsequent diagnostic steps. Look for leaks, unusual noises, or other visible problems.

- Component Isolation: Once a general area of concern is identified, pinpoint the specific component suspected to be causing the issue. This might involve checking wiring connections, sensors, actuators, or other relevant components. Thorough documentation of observations is vital.

- System Verification: Use diagnostic tools to verify the functionality of the suspected component and related systems. Data gathered from the OBD system will be crucial in confirming or refuting the hypothesis. Analyzing the data will help in identifying the specific problem.

Diagnostic Tools

Various tools are available for performing OBD diagnostics. Choosing the right tool depends on the specific needs and the complexity of the vehicle’s system.

- OBD Scanners: These devices connect to the vehicle’s OBD port and retrieve diagnostic trouble codes (DTCs), live data streams, and other system information. Different scanners cater to various vehicle makes and models. Advanced scanners offer more comprehensive data analysis and potentially more specialized functions.

- Diagnostic Software: Software programs, often used in conjunction with a scanner, provide a more detailed and user-friendly interface for analyzing data. Such software can provide more advanced graphing capabilities, comprehensive troubleshooting guides, and detailed descriptions of DTCs.

- Specialized Tools: Some vehicles might require specialized tools, like oscilloscopes, to capture and analyze electrical signals. These tools offer a more in-depth view of system performance, enabling technicians to diagnose complex electrical issues.

Connecting and Communicating with the OBD System

Connecting to the OBD system typically involves plugging a diagnostic tool into the vehicle’s OBD-II port, which is a standardized port found in most vehicles manufactured after 1996. The tool then establishes a communication link with the vehicle’s onboard computer.

- OBD-II Port Location: The location of the OBD-II port varies among vehicles. It’s often located under the dashboard or in the engine compartment. Consult the vehicle’s owner’s manual for specific details.

- Communication Protocols: OBD systems utilize standardized communication protocols (e.g., CAN bus) to transmit data. The diagnostic tool needs to be compatible with the vehicle’s communication protocol to successfully receive data.

- Troubleshooting Connection Issues: If connection issues arise, verify the OBD port’s proper function and ensure the diagnostic tool is compatible with the vehicle’s system. Checking for loose connections or damaged wiring can help resolve the issue.

Information Displayed by Diagnostic Tools

Diagnostic tools provide a wealth of information about the vehicle’s systems.

- Diagnostic Trouble Codes (DTCs): These codes identify specific faults within the vehicle’s systems. Each code corresponds to a particular problem, and detailed descriptions are available in the vehicle’s repair manual or online resources. For example, a P0300 code typically indicates a misfire detected in multiple cylinders.

- Live Data: Live data displays real-time readings from various sensors and actuators. This information allows for monitoring of engine parameters, such as fuel pressure, coolant temperature, or oxygen sensor readings, under various operating conditions. Monitoring live data during a driving test can provide insights into the vehicle’s behavior.

- Data Graphs: Graphs help visualize the trends of live data, providing valuable insights into the behavior of various vehicle systems. They can reveal patterns or fluctuations in the data that might indicate the source of the problem.

Using OBD Data for Troubleshooting, OBD systems

OBD data provides valuable insights into vehicle problems.

- Analyzing DTCs: Carefully review the DTCs provided by the diagnostic tool. Match the codes with the descriptions in the repair manual to identify the specific component or system causing the problem. For instance, a P0420 code indicates a problem with the catalytic converter system.

- Interpreting Live Data: Analyzing live data can provide clues to the malfunction’s root cause. Compare the readings with the expected values and look for anomalies or trends. For example, a significant drop in fuel pressure could indicate a fuel pump issue.

- Correlation with Symptoms: Relate the diagnostic data to the vehicle’s symptoms. Combining data with observations can pinpoint the root cause of the problem more accurately. A noticeable decrease in acceleration combined with a specific DTC could indicate a fuel delivery issue.

OBD System Applications

OBD systems, initially designed for diagnostic purposes, have evolved into powerful tools with a broad range of applications beyond simple fault detection. Their integration with vehicle systems and data allows for enhanced maintenance, improved fleet management, and optimized performance. This expanded functionality leverages the real-time data streams available through the OBD port.The core function of an OBD system, detecting and reporting faults, has evolved into more proactive and comprehensive roles, supporting the entire vehicle lifecycle from maintenance to performance enhancement.

By providing access to crucial vehicle data, OBD systems allow for informed decisions, leading to improved operational efficiency and reduced costs.

Vehicle Maintenance and Repair

OBD systems significantly aid in vehicle maintenance and repair by providing precise diagnostic information. This data enables technicians to pinpoint the root cause of a problem quickly, minimizing downtime and repair costs. By identifying potential issues before they escalate, preventative maintenance strategies can be implemented, further extending vehicle lifespan and reliability. Real-time data also helps to understand the operational patterns of vehicles, aiding in proactive maintenance schedules.

Fleet Management and Vehicle Tracking

OBD systems are increasingly utilized in fleet management, offering comprehensive insights into vehicle performance and location. Real-time data acquisition enables tracking of vehicle location, fuel consumption, and operational hours, allowing for efficient routing and resource allocation. This data-driven approach facilitates the optimization of delivery routes and improves overall fleet efficiency. Remote diagnostics and monitoring are also key features, enabling prompt identification and resolution of potential issues.

Integration with Aftermarket Accessories

Many aftermarket accessories, such as performance tuning devices or advanced safety systems, now integrate with OBD systems. This integration allows these accessories to communicate with the vehicle’s computer system, enabling enhanced functionality and optimal performance. This allows for the safe and effective use of these components. For example, a performance chip may adjust engine parameters according to the vehicle’s data, enabling increased efficiency or performance.

Vehicle Performance Monitoring and Optimization

OBD systems provide valuable data for monitoring and optimizing vehicle performance. The real-time data streams allow for adjustments to driving styles or engine parameters for enhanced fuel efficiency or performance. Analysis of this data allows for a more informed understanding of how the vehicle operates under various conditions. This enables customized vehicle settings for specific needs and environments, contributing to improved fuel economy and reducing emissions.

Software applications can further analyze data to generate detailed performance reports, allowing for strategic adjustments.

OBD System Standards and Regulations

OBD systems are governed by a complex web of standards and regulations, crucial for ensuring interoperability, safety, and environmental compliance across different vehicle markets. These standards dictate the technical specifications of OBD systems, from the diagnostic protocols used to communicate with the vehicle’s electronic control units (ECUs) to the reporting formats for diagnostic trouble codes (DTCs). Understanding these standards is vital for both vehicle manufacturers and technicians involved in diagnostics and repairs.Compliance with these standards is paramount for vehicles to function as intended and be accepted in various regions.

Differences in these standards can affect the design, manufacturing, and repair processes of vehicles. Furthermore, evolving environmental concerns and safety requirements necessitate continuous updates to these regulations.

OBD Standards Across Different Countries and Regions

Various countries and regions have implemented their own OBD standards, reflecting their unique regulatory frameworks. These standards often differ in their scope, complexity, and specific requirements. The variations stem from factors such as environmental regulations, safety standards, and technological advancements.

OBD systems are crucial for diagnosing car issues. Pairing them with a Bluetooth FM transmitter, like the one available at Bluetooth FM transmitter , allows you to stream audio from your phone to your car stereo, enhancing the overall driving experience. This can be particularly helpful for monitoring diagnostics alongside your audio, making OBD systems even more valuable.

Key Requirements and Compliance Standards

The core requirements of OBD standards usually include the availability of diagnostic ports, standardized communication protocols, and the capability to store and report diagnostic trouble codes (DTCs). Manufacturers must adhere to these standards during vehicle design and manufacturing, ensuring that the vehicle meets the requirements of the respective region.

Role of Government Agencies in Setting OBD Standards

Government agencies play a critical role in establishing and enforcing OBD standards. These agencies, often responsible for environmental protection, vehicle safety, and consumer protection, develop and update regulations to address evolving concerns and technological advancements. They often work collaboratively with industry stakeholders to ensure effective implementation and minimize any potential disruptions. Examples include the Environmental Protection Agency (EPA) in the United States and equivalent organizations in other countries.

Implications of Non-Compliance with OBD Standards

Non-compliance with OBD standards can result in significant consequences for vehicle manufacturers. Penalties may include fines, recalls, and limitations on vehicle sales in specific regions. Moreover, non-compliance can lead to safety concerns and environmental issues, potentially impacting consumer trust and public perception. For example, a vehicle failing to meet emissions standards could face substantial fines and be restricted from sale in certain jurisdictions.

Influence of OBD Standards on Vehicle Design and Manufacturing

OBD standards significantly influence vehicle design and manufacturing processes. Manufacturers must incorporate the required diagnostic ports, communication protocols, and data storage capabilities into their vehicle designs. Furthermore, these standards often drive the development of advanced diagnostic tools and software for technicians to ensure accurate and efficient diagnostics. The increased complexity of modern vehicles necessitates a greater emphasis on the design and implementation of OBD systems.

OBD System Security

OBD systems, while crucial for vehicle diagnostics and maintenance, present potential security vulnerabilities. Malicious actors could exploit these vulnerabilities to gain unauthorized access, potentially leading to significant harm. Understanding these risks and implementing robust security measures are essential for protecting vehicles and ensuring the integrity of the data transmitted through the OBD system.

Potential Security Vulnerabilities

OBD systems utilize communication protocols that can be susceptible to various attacks. These protocols, designed primarily for diagnostic purposes, might lack adequate security measures. This allows attackers to potentially gain access to the vehicle’s control systems, manipulate data, and ultimately control the vehicle’s functions. Compromised systems could lead to unauthorized access, theft, and safety hazards.

Methods and Techniques for Compromising OBD Systems

Several methods can be employed to compromise an OBD system. These range from exploiting known vulnerabilities in the communication protocols to utilizing physical access to manipulate hardware components. Sophisticated attacks might involve using specially designed tools and software to exploit security weaknesses in the system. Another method is exploiting software vulnerabilities within the vehicle’s control modules to gain unauthorized access.

Examples of OBD System Hacking Incidents

Reported incidents highlight the potential for OBD system compromises. Some examples involve unauthorized access to vehicle control systems allowing for remote control and manipulation of functions. These incidents demonstrate the importance of securing OBD systems and protecting against such malicious activities. Further, research and documented incidents reveal potential for remote theft or hijacking.

Security Measures to Protect OBD Systems

Implementing security measures is crucial to mitigate the risk of attacks. One such measure is utilizing strong authentication and authorization mechanisms to restrict access to the OBD system. Employing encryption techniques for data transmission helps safeguard sensitive information. Adding hardware-based security features like tamper-resistant components and secure microcontrollers can effectively prevent unauthorized modifications.

Best Practices for Securing OBD Systems and Vehicles

Robust security practices encompass multiple aspects. Regular software updates and patching are critical for addressing known vulnerabilities. Implementing security protocols within the vehicle’s architecture, particularly those focused on authentication and authorization, is essential. Additionally, incorporating physical security measures, like tamper-resistant seals and secure storage for the OBD interface, can help deter unauthorized access. Vehicle manufacturers and researchers should continue to prioritize the development and implementation of robust security measures to prevent malicious actors from compromising OBD systems.

Future Trends in OBD Systems

OBD systems are constantly evolving, driven by advancements in automotive technology and the need for improved vehicle performance, safety, and efficiency. The future of OBD systems promises significant integration with advanced technologies, enabling more sophisticated diagnostics and predictive maintenance capabilities. This evolution will ultimately benefit both vehicle owners and manufacturers.The next generation of OBD systems will be characterized by greater connectivity and data processing capabilities.

This will allow for real-time monitoring of vehicle health and performance, leading to earlier detection of potential issues and proactive maintenance. This proactive approach will save money and time by preventing costly repairs.

Advanced Technology Integration

Future OBD systems will increasingly incorporate artificial intelligence (AI) and machine learning (ML) algorithms. These technologies will enable the analysis of vast amounts of data collected from various sensors within the vehicle. AI-powered diagnostics will go beyond simply identifying existing problems; they will be able to predict potential failures before they occur. This predictive capability will be instrumental in improving vehicle reliability and extending the lifespan of vehicle components.

Predictive Maintenance

OBD systems will play a critical role in implementing predictive maintenance strategies. By analyzing sensor data, AI algorithms can identify patterns indicative of potential component failures. This allows for proactive maintenance schedules, reducing downtime and repair costs. For instance, a system might predict that a specific engine part is likely to fail within the next few months, prompting a timely replacement before a complete engine failure occurs.

Cloud Computing and Remote Diagnostics

Cloud computing will be essential for handling the vast amounts of data generated by modern vehicles. The cloud will facilitate remote diagnostics and over-the-air (OTA) updates. Remote diagnostics allow technicians to access vehicle data and diagnose issues remotely, reducing repair time and costs. This approach is particularly valuable for vehicles in remote locations or for complex issues that may require specialized expertise.

Furthermore, OTA updates will enable manufacturers to deploy software patches and improvements directly to vehicles, enhancing safety and performance without requiring a physical visit to a service center.

Emerging Applications and Use Cases

Future OBD systems will extend their capabilities beyond traditional diagnostics. These systems will be integrated into vehicle-to-everything (V2X) communication networks, allowing for seamless communication between vehicles, infrastructure, and other connected devices. This will open up a wide range of possibilities for enhanced safety and efficiency. For example, an OBD system might detect a potential collision risk and alert the driver, or it might optimize traffic flow by communicating with other vehicles and traffic management systems.The integration of advanced driver-assistance systems (ADAS) with OBD systems will lead to a more comprehensive and proactive approach to vehicle safety and performance.

Real-time data exchange between ADAS and OBD systems can enhance the capabilities of these systems and improve overall driving experiences.

Troubleshooting OBD System Issues

Troubleshooting OBD systems involves identifying and resolving problems impacting their functionality. Effective diagnosis requires understanding the various components, their interactions, and common failure modes. This process often involves using diagnostic tools, interpreting diagnostic trouble codes (DTCs), and performing systematic checks.

Common OBD System Problems

Numerous issues can affect OBD systems, ranging from minor wiring problems to more complex hardware failures. These problems can manifest as communication errors, incorrect readings, or a complete lack of system response. Understanding the potential causes is crucial for effective troubleshooting.

Methods and Procedures for Troubleshooting

Systematic procedures are essential for accurate OBD system troubleshooting. These methods involve a combination of visual inspections, diagnostic tool usage, and methodical testing. Proper documentation of observations and test results is vital for tracking progress and identifying the root cause.

Troubleshooting Communication Problems

Communication problems between the OBD system and diagnostic tools are a frequent issue. These problems can stem from various sources, including faulty wiring, degraded connectors, or issues with the diagnostic tool itself. Careful examination of wiring, connectors, and the diagnostic tool’s functionality is essential. Verification of correct diagnostic tool programming and compatibility with the vehicle’s OBD system is also crucial.

Troubleshooting Wiring Issues

Wiring problems are a common source of OBD system malfunction. Issues such as loose connections, damaged wires, or short circuits can disrupt communication and data transmission. Visual inspection of wiring harnesses and connectors, along with thorough testing using appropriate diagnostic tools, is necessary. Using a multimeter to check continuity and voltage levels can pinpoint specific wiring problems.

Troubleshooting Hardware Issues

Hardware failures within the OBD system itself can lead to various problems. Examples include malfunctioning sensors, faulty control modules, or damaged connectors within the system. Careful examination of the hardware components, using diagnostic tools to identify specific faults, and comparing readings against expected values is crucial. Replacing faulty components and ensuring proper installation are necessary steps in resolving hardware issues.

Diagnosing and Resolving OBD System Problems: Example Scenarios

Troubleshooting steps for different types of problems vary depending on the nature of the issue. Here are examples:

- Example 1: No Communication with Diagnostic Tool

– First, ensure the diagnostic tool is compatible with the vehicle’s OBD system. Verify proper connection to the vehicle’s OBD port. Check the power supply and connectivity of the diagnostic tool. If the issue persists, inspect the wiring harness for any signs of damage or loose connections. Test the OBD port itself for proper functionality. - Example 2: Erroneous Sensor Readings

– Confirm the sensor is correctly connected and functioning. Compare the sensor’s readings to expected values from a reliable source. Verify sensor calibration, as an issue with calibration can result in incorrect readings. Replace the sensor if necessary, and ensure proper installation. - Example 3: Check Engine Light On

– Retrieve the diagnostic trouble code (DTC). Consult a reliable source to understand the meaning of the DTC. Investigate the potential causes associated with the DTC. For instance, if the DTC indicates a problem with the oxygen sensor, verify the sensor’s proper operation and replacement if required.

Identifying and Resolving Communication Errors

Identifying and resolving communication errors requires a systematic approach. First, ensure that the diagnostic tool is properly connected and configured. Check for any wiring issues, loose connections, or damaged components in the OBD system’s communication pathways. Compare the communication data with the expected parameters. Use appropriate diagnostic tools to isolate the source of the error.

OBD System Data Representation

OBD systems rely on standardized data formats to convey information about the vehicle’s performance and diagnostics. These formats ensure that diagnostic tools from different manufacturers can effectively communicate and interpret the data. Understanding this data representation is crucial for technicians and engineers to accurately analyze issues and perform repairs.

OBD Data Formats

This section details the structured formats used to represent data within OBD systems. Properly interpreting these formats is essential for accurate diagnostic analysis.

| Data Type | Description | Example |

|---|---|---|

| PID (Parameter ID) | A unique identifier for a specific vehicle parameter, like engine speed or fuel pressure. | 01 (engine speed) |

| Data Value | The actual measured value of the parameter. | 3000 RPM |

| Units | The units of measurement for the data value. | RPM |

| Calibration Data | Data that corrects or adjusts the measured values. | Correction factor for altitude |

| Diagnostic Trouble Codes (DTCs) | Codes that indicate specific malfunctions in the vehicle system. | P0301 (Misfire on Cylinder 1) |

Data Structure and Organization

OBD data is structured in a way that allows diagnostic tools to readily access and interpret specific information. The data is organized into messages, often referred to as frames, containing multiple PIDs. Each PID has a specific position within the message, enabling efficient extraction of relevant data.

The structure ensures that diagnostic tools can rapidly identify the required parameters and efficiently process them.

For example, a single message might contain information on engine speed, coolant temperature, and oxygen sensor readings, all organized for quick access.

Data Interpretation by Diagnostic Tools

Diagnostic tools employ algorithms and specific protocols to interpret OBD data. This involves comparing the measured values against pre-defined thresholds and standards. Discrepancies from these standards or expected values trigger diagnostic trouble codes (DTCs).

Diagnostic tools use a combination of pre-programmed knowledge and real-time analysis to interpret OBD data.

For instance, if the engine speed consistently exceeds a safe operating range, the diagnostic tool would identify a potential problem and trigger a DTC.

Data Visualization Tools

Data visualization tools are instrumental in understanding trends and patterns in OBD data. These tools allow technicians to visually represent data over time, enabling a more comprehensive understanding of vehicle performance.

Visual representations make complex data sets easier to understand and allow for the identification of patterns that might not be evident from numerical data alone.

Graphs and charts displaying data like fuel consumption, engine temperature, and emission levels can provide a clear picture of system performance and help pinpoint anomalies.

Best Practices for Data Representation

Clear and concise representation of OBD data is crucial for efficient diagnostics. Consistency in data formatting, including units of measurement, is essential. Using standardized formats simplifies data exchange and interpretation between different diagnostic tools.

- Use a consistent data format across all vehicle models for ease of analysis.

- Ensure data values are displayed with appropriate units.

- Provide clear labels for all parameters.

- Implement data validation to ensure accuracy and reliability.

Summary

In conclusion, OBD systems have become indispensable for vehicle maintenance, repair, and performance monitoring. Their multifaceted applications extend beyond basic diagnostics, impacting fleet management, security, and future vehicle technologies. Understanding the intricacies of OBD systems empowers users to make informed decisions regarding vehicle maintenance and troubleshooting.

General Inquiries: OBD Systems

What are the common causes of OBD system communication errors?

Faulty wiring, damaged connectors, or a malfunctioning OBD II port are some common causes of communication issues. Poor electrical connections, a damaged diagnostic tool, or even a vehicle’s internal software conflicts can also disrupt communication.

What are the different types of diagnostic trouble codes (DTCs)?

DTCs are categorized based on the system they relate to, such as engine, transmission, or emissions. They can indicate a wide range of issues, from minor problems to major component failures.

How can I use OBD data for troubleshooting vehicle problems?

OBD data provides valuable insights into the vehicle’s performance. Diagnostic tools display live data, trouble codes, and historical data, allowing for targeted troubleshooting and efficient repair.

What are the potential security vulnerabilities in OBD systems?

OBD systems are susceptible to hacking due to their communication protocols. Malicious actors could potentially manipulate vehicle functions, causing damage or theft. Strong security measures are vital to mitigate these risks.