NVH analysis is crucial in product development, ensuring a positive user experience. This guide delves into the intricacies of Noise, Vibration, and Harshness (NVH) analysis, covering everything from fundamental concepts to advanced techniques and case studies. Understanding NVH is vital for optimizing product quality and performance across various industries.

This comprehensive guide examines the core elements of NVH analysis, from the initial stages of design to the final testing phases. It explores various methods, tools, and procedures, providing readers with a deep understanding of the process.

Introduction to NVH Analysis

Noise, Vibration, and Harshness (NVH) encompass the auditory and physical sensations experienced by users interacting with a product. It encompasses a broad spectrum of unwanted sounds and sensations, from the rumble of an engine to the squeak of a door. Effective NVH analysis is crucial for optimizing user experience and product performance.NVH is a critical consideration throughout the design and development lifecycle of any product, especially those intended for human interaction.

Properly addressing NVH concerns leads to improved product quality, enhanced user satisfaction, and often, increased market competitiveness. Neglecting NVH can result in a product that is perceived as unreliable, uncomfortable, or simply unpleasant to use.

Significance of NVH in Product Design

NVH considerations play a vital role in the overall success of a product. It directly impacts the user experience, influencing factors like perceived quality, comfort, and even safety. Products with poor NVH characteristics can be deemed inferior by users, regardless of other positive features. A well-tuned NVH design contributes to a product’s perceived value, leading to enhanced brand reputation and consumer loyalty.

Industries Requiring Comprehensive NVH Analysis

NVH analysis is indispensable in numerous industries. Automotive manufacturers prioritize NVH to ensure smooth operation and reduce noise pollution. Home appliance manufacturers rely on NVH analysis to minimize noise levels and improve user comfort. Consumer electronics, aerospace, and even heavy machinery industries all benefit from robust NVH assessments. Each industry requires specific NVH criteria tailored to its unique operational environment and user needs.

Impact of NVH on User Experience

A well-engineered NVH strategy enhances the user experience in significant ways. A quiet, smooth-running engine translates to a more pleasant driving experience for car owners. Reduced vibrations in home appliances enhance user comfort and reduce fatigue. Minimizing harsh noises in electronic devices enhances the user interface and reduces stress during operation. Ultimately, a refined NVH design contributes to a positive, productive, and comfortable interaction with the product.

Common NVH Issues

Understanding the various NVH issues is fundamental to effective analysis and mitigation strategies. The following table provides a concise overview of common problems:

| Category | Examples |

|---|---|

| Engine Noise | Engine rattling, knocking, or whining sounds; vibrations felt throughout the vehicle |

| Tire Noise | Tire squealing, road noise transmitted to the cabin; uneven tire wear |

| Body Panel Resonance | Vibrations and rattling sounds from the vehicle’s body panels; resonance at specific frequencies |

| HVAC System Noise | Unwanted sounds from the heating, ventilation, and air conditioning system; air leaks and air flow issues |

| Interior Noise | Wind noise, squeaking or creaking sounds from interior components; poor soundproofing |

Methods for NVH Analysis

Numerous techniques are employed in NVH (Noise, Vibration, and Harshness) analysis to identify and mitigate unwanted sounds and vibrations in various products. These methods range from experimental testing to sophisticated simulations, allowing engineers to pinpoint the root causes of NVH issues and implement effective solutions. A thorough understanding of these methods is crucial for achieving optimal product performance and user experience.

Modal Analysis

Modal analysis is a crucial technique for determining the natural frequencies and vibration modes of a structure. By exciting the structure at different frequencies, engineers can identify the resonant frequencies, where the structure vibrates most intensely. This information is critical for designing structures that avoid undesirable resonance issues. Knowing the resonant frequencies allows engineers to avoid operating the product near these frequencies, thus preventing excessive vibrations.

Modal analysis often involves using specialized equipment such as accelerometers and modal analysis software to capture and interpret the vibration data. For example, in automotive engineering, modal analysis helps in designing car bodies that resist vibrations and unwanted sounds at specific driving speeds.

Acoustic Analysis

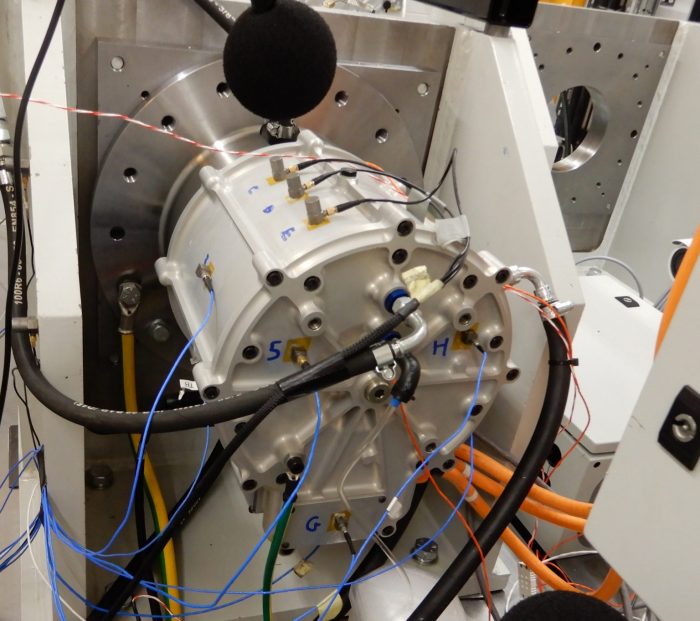

Acoustic analysis focuses on the measurement and characterization of sound generated by a product. This method involves using microphones to capture sound pressure levels at various points around the product. Sophisticated software then processes this data to identify the sources of noise and quantify their contributions. For instance, in the aerospace industry, acoustic analysis helps in designing quieter aircraft engines.

Analyzing sound pressure levels in different frequencies provides crucial information about noise sources. Further, acoustic analysis plays a vital role in understanding how sound propagates and interacts with the surrounding environment.

Durability Testing

Durability testing evaluates the long-term performance of a product under various conditions. This method is essential for understanding how NVH characteristics might change over time, due to factors like material fatigue, component wear, and environmental conditions. For instance, in consumer electronics, durability testing ensures that the product’s sound and vibration levels remain consistent throughout its lifespan. This type of testing involves subjecting the product to extensive use cycles, simulating real-world usage conditions.

This allows engineers to predict how NVH characteristics will change over time, and identify potential degradation issues. Durability testing is crucial for ensuring the product’s long-term NVH performance and reliability.

Role of Simulations in NVH Analysis

Simulations are powerful tools for predicting and analyzing NVH behavior before physical prototypes are built. Computational models allow engineers to simulate the vibration and acoustic responses of a product under various operating conditions, offering a cost-effective way to identify and address NVH issues early in the design process. Simulations, for example, allow engineers to predict how a new car body design will perform under different driving conditions, thus reducing the time and cost of testing.

Software tools can model the interaction between components, predict the sound generated by different parts of a product, and simulate the effects of vibrations on the structure.

Comparison of NVH Testing Equipment

Various instruments are used for NVH testing, each with its own capabilities and limitations. For example, accelerometers measure vibration levels, microphones record sound pressure, and specialized vibration shakers are used to excite structures. Different testing equipment has varying accuracy, sensitivity, and range of measurement. The choice of equipment depends on the specific needs of the analysis, considering the type of product and the frequency range of interest.

Engineers must carefully select equipment appropriate for their analysis, and be mindful of the limitations of each instrument.

Applications of NVH Analysis Methods

| Analysis Method | Automotive | Aerospace | Consumer Electronics |

|---|---|---|---|

| Modal Analysis | Analyzing chassis vibrations, suspension components | Assessing aircraft structural integrity, engine vibration | Evaluating speaker vibrations, headphone noise |

| Acoustic Analysis | Measuring road noise, engine noise | Reducing noise from jet engines, cabin noise | Testing speaker frequency response, minimizing fan noise |

| Durability Testing | Evaluating component wear, long-term noise levels | Assessing engine performance over extended periods, fatigue of materials | Testing product lifespan, stability of sound output |

Data Acquisition and Measurement

Data acquisition is a critical step in NVH analysis, forming the foundation for accurate assessments and subsequent improvements. Precise measurement of noise, vibration, and harshness is essential to identify problematic sources and quantify their effects. This process involves selecting appropriate sensors, implementing suitable measurement techniques, and ensuring the reliability of the gathered data.

Methods for Data Acquisition

Various methods are employed for collecting NVH data, each with its own strengths and limitations. A crucial consideration is the nature of the test environment and the specific characteristics of the system under analysis. Careful planning and selection of the appropriate method is critical for accurate and meaningful results.

- Sound Level Measurement: Sound level meters are utilized to quantify sound pressure levels in various environments. These instruments are calibrated to specific standards, allowing for consistent and comparable measurements. Different types of sound level meters cater to diverse applications, ranging from simple measurements in a quiet office to complex analyses in industrial settings.

- Vibration Measurement: Accelerometers and other vibration sensors are essential for measuring vibration levels. They convert mechanical vibrations into electrical signals that can be processed and analyzed. The choice of accelerometer depends on factors like the frequency range of interest, the amplitude of vibration, and the environment where the measurements are taken.

- Harshness Measurement: Harshness assessments typically involve subjective evaluations or objective measurements using specialized algorithms and hardware. The objective measures quantify parameters like the perceived harshness and roughness of sounds and vibrations. These data points can be analyzed to identify the sources of harshness and improve the overall user experience.

Role of Sensors and Transducers

Sensors and transducers play a vital role in converting physical phenomena (noise, vibration, and harshness) into measurable electrical signals. Their characteristics significantly impact the accuracy and reliability of the data. Careful selection and proper calibration are essential for obtaining precise results.

- Sensor Types: Various sensor types are used in NVH analysis, each with its own range of frequencies, sensitivity, and operating conditions. Selecting the appropriate sensor is critical for capturing the relevant data accurately.

- Transducer Characteristics: Transducers are crucial in converting physical vibrations into electrical signals. Their sensitivity, frequency response, and linearity significantly affect the quality of the data collected.

Measurement Techniques for Noise, Vibration, and Harshness

Different measurement techniques are used for noise, vibration, and harshness, depending on the specific parameters of interest. These techniques encompass diverse methods, from simple recordings to complex signal processing algorithms.

- Noise Measurement Techniques: Noise measurement techniques include sound level meter measurements, which capture sound pressure levels over time. Sound intensity measurements and acoustic cameras can also be utilized to pinpoint the source of the noise.

- Vibration Measurement Techniques: Vibration measurement techniques include using accelerometers to measure acceleration, velocity, and displacement. Frequency analysis techniques such as Fast Fourier Transform (FFT) are often used to identify dominant vibration frequencies.

- Harshness Measurement Techniques: Harshness measurement techniques are often subjective, relying on human perception. However, objective methods such as spectral analysis and signal processing algorithms can quantify harshness characteristics.

Calibration and Data Accuracy

Calibration is a critical step in NVH data acquisition. Ensuring accuracy in the measurement process is paramount. Calibration procedures and protocols are defined by industry standards to ensure consistent results across different measurement sessions.

- Calibration Procedures: Calibration ensures the accuracy of sensors and transducers. The calibration process involves comparing the instrument’s output to a known standard. This process ensures that the measurements are reliable and consistent.

- Data Accuracy: Data accuracy is a key aspect of NVH analysis. Errors in measurement can lead to inaccurate analysis and ineffective solutions. Proper calibration, appropriate sensor selection, and meticulous data handling are crucial to ensure high accuracy.

Sensor Types for NVH Data Acquisition

Different sensor types are suitable for different NVH measurement tasks. The selection process considers factors like the frequency range, sensitivity, and environmental conditions.

| Sensor Type | Application | Advantages | Disadvantages |

|---|---|---|---|

| Accelerometer | Vibration measurement | Wide frequency range, good sensitivity | Susceptible to shock, may require specialized mounting |

| Microphone | Noise measurement | High sensitivity, compact size | Susceptible to wind noise, may require careful placement |

| Strain Gauge | Structural vibration | High sensitivity to small deformations | Requires careful bonding and mounting |

| Pressure Transducer | Acoustic pressure measurement | Precise measurement of pressure changes | Can be bulky, requires careful shielding |

NVH Analysis Tools and Software

A critical aspect of NVH (Noise, Vibration, and Harshness) analysis is the utilization of specialized software tools. These tools facilitate the efficient processing, visualization, and interpretation of data collected during NVH testing. Proper selection and effective use of these tools are instrumental in identifying and addressing NVH issues, ultimately leading to improved product quality and user experience.Various software packages are available, each with specific strengths and weaknesses.

Understanding these capabilities is key to selecting the optimal tool for a given application. This section delves into common NVH analysis software, highlighting their features and demonstrating their application in data analysis and visualization.

Common NVH Analysis Software Tools

Several software tools are commonly employed for NVH analysis, catering to diverse needs and industry applications. These tools often feature advanced algorithms and functionalities that facilitate detailed analysis of complex data sets.

- LMS Virtual.Lab: This widely used software package offers comprehensive capabilities for simulating and analyzing NVH phenomena. Its capabilities extend to modeling vehicle components, such as engines, transmissions, and body structures, to predict and analyze their contributions to noise and vibration. This tool is often used in automotive and aerospace industries for virtual prototyping and optimization of design parameters.

NVH analysis is crucial for evaluating a vehicle’s overall acoustic performance. A key component affecting this is the dual clutch transmission, which, through its dual clutch transmission design, can contribute to significant noise and vibration characteristics. Understanding these characteristics is a vital part of the NVH analysis process, and optimizing for a smooth, quiet ride.

- MATLAB/Simulink: MATLAB, a powerful platform for numerical computation and visualization, combined with Simulink, a simulation environment, provides a flexible and adaptable solution for NVH analysis. Users can create custom models and algorithms to simulate and analyze NVH behavior in various systems. This flexibility is beneficial in industries requiring tailored analysis, such as research and development.

- ANSYS: ANSYS is a widely used finite element analysis (FEA) software suite that can be leveraged for NVH analysis. It allows for the simulation of complex vibration and sound propagation, helping to identify and address the source of noise and vibration within structures. This software is often used for evaluating the structural integrity and sound characteristics of products, which is useful in industries such as machinery and construction.

- HyperMesh: This software is primarily used for pre- and post-processing of finite element models. Although not a dedicated NVH software, it can be integrated with other tools like ANSYS or Abaqus for comprehensive analysis. Its strength lies in the creation and management of complex 3D models of mechanical systems, providing a crucial preparatory step for NVH analysis.

Features and Functionalities

These tools provide diverse features for efficient NVH analysis. The selection of the appropriate software depends on the specific analysis requirements. Features like signal processing, modal analysis, and noise source identification are often critical in achieving the desired level of understanding.

- Signal Processing: NVH software typically includes tools for signal filtering, spectral analysis (like FFT), and time-domain analysis, allowing users to isolate and identify various noise and vibration components.

- Modal Analysis: The ability to determine the natural frequencies and mode shapes of a structure is essential for predicting vibration behavior. Software tools often provide sophisticated modal analysis tools, aiding in the identification of resonance issues.

- Noise Source Identification: Advanced tools facilitate the identification of specific noise sources, allowing engineers to focus on the root causes and implement targeted solutions.

- Visualization and Reporting: Effective visualization of results is critical for interpretation. Sophisticated plots, charts, and reports are essential for communicating findings and presenting recommendations.

Selecting the Appropriate Software

Selecting the ideal NVH analysis software involves careful consideration of factors such as the specific application, required analysis types, existing infrastructure, and budget constraints. Considering the available resources is critical to the selection process.

- Industry Needs: The automotive industry, for example, often relies on specialized software tailored to vehicle dynamics and acoustic characteristics.

- Complexity of the Analysis: Complex systems might require software with advanced simulation capabilities.

- Data Volume and Type: The volume and type of data collected will influence the choice of software, which must be able to process and analyze the data effectively.

Data Visualization and Analysis Example (using LMS Virtual.Lab)

Consider a scenario where an automotive manufacturer wants to analyze the engine noise of a new vehicle model. Using LMS Virtual.Lab, engineers can import acoustic measurements and generate frequency response functions. This data can be visualized as frequency spectra and then used to identify noise sources, aiding in design modifications.

NVH Design and Optimization: NVH Analysis

Effective NVH (Noise, Vibration, and Harshness) analysis isn’t just about identifying problems; it’s a crucial tool for proactive design decisions. By integrating NVH considerations throughout the design process, manufacturers can significantly reduce development costs and time-to-market. This approach ensures that the final product meets stringent customer expectations for a smooth and quiet experience.NVH analysis provides valuable insights into the source and magnitude of noise, vibration, and harshness within a product.

These insights directly inform design modifications, material selection, and iterative improvements. By anticipating and mitigating potential NVH issues early in the design cycle, significant reductions in post-production rework and customer complaints can be achieved.

Design Modifications for NVH Reduction

Design modifications play a critical role in mitigating NVH problems. These modifications can range from simple changes in component geometry to more complex structural alterations. Effective modifications target the root causes of unwanted noise, vibration, and harshness. A thorough understanding of the source and transmission pathways of these issues is essential for implementing effective solutions.

- Geometry Adjustments: Modifying component shapes, such as fillets, radii, or surface textures, can alter the way sound waves propagate and interact with the surrounding environment. For instance, reducing sharp edges on engine covers can significantly decrease the amount of reflected noise. Properly engineered surface textures can also absorb or diffuse sound, reducing the overall noise level.

- Structural Stiffening: Increasing the structural stiffness of components can help reduce vibration transmission. This often involves using thicker materials or adding reinforcing elements, such as ribs or stiffeners. An example is strengthening the chassis of a vehicle to decrease vibrations felt by the occupants.

- Vibration Isolation: Implementing vibration isolation techniques can prevent vibrations from propagating through the structure. This often involves incorporating damping materials or isolating components on mounts. A classic example is using shock absorbers in automobiles to isolate the body from road vibrations.

- Sound Deadening: Incorporating sound-absorbing materials or sound-blocking barriers can significantly reduce noise levels. This might involve applying acoustic foams to internal components or adding sound insulation to the vehicle’s body panels.

Material Selection Based on NVH Performance

Material selection is a critical aspect of NVH optimization. Different materials exhibit varying levels of stiffness, damping, and sound absorption characteristics. Choosing the right material for each component can significantly impact the overall NVH performance of the product.

- Acoustic Properties: Some materials inherently absorb sound better than others. For example, certain polymers and foams have excellent sound absorption properties, making them ideal for interior sound deadening applications in vehicles or appliances.

- Damping Capabilities: Materials with high damping capacity can effectively absorb and dissipate vibrations. Metallic alloys with high damping properties can be incorporated into critical structural components to minimize unwanted vibrations.

- Stiffness: The stiffness of a material impacts how it reacts to external forces and vibrations. A stiffer material generally transmits less vibration, although it may also amplify certain frequencies. Choosing the right stiffness level is crucial to avoid resonances and vibrations.

Iterative Improvement Process

Improving NVH performance is an iterative process. It typically involves multiple design cycles, analysis, and modifications. Each iteration builds upon the previous one, progressively reducing NVH issues.

- Analysis & Simulation: Utilizing sophisticated NVH analysis tools, simulations help predict and evaluate the NVH performance of different design options before physical prototyping. This predictive capability helps to identify potential problems early in the design process.

- Prototyping & Testing: Physical prototypes are built and tested to validate the simulated results and identify any unexpected issues. Testing provides real-world data on the NVH performance of the design.

- Refinement & Iteration: Based on the test results, design modifications are made to address identified issues. The cycle repeats until the desired NVH performance is achieved.

Design Option Comparison Table

| Design Option | Material | Predicted NVH Score (0-100, higher is better) | Cost (USD) | Manufacturing Complexity |

|---|---|---|---|---|

| Option A | High-damping steel alloy | 85 | 120 | Medium |

| Option B | Composite material with sound-absorbing foam | 92 | 150 | High |

| Option C | Standard steel | 70 | 100 | Low |

This table provides a simplified comparison. Actual NVH scores and costs can vary significantly based on specific design parameters and manufacturing processes.

NVH Testing Procedures

NVH testing procedures are crucial for evaluating and improving the acoustic and vibrational characteristics of a product. These procedures dictate the standardized methods for data collection, ensuring consistent and reliable results across different tests and locations. Thorough testing procedures are essential for identifying potential noise and vibration issues early in the design process, leading to more efficient and effective solutions.

Standard Testing Procedures for NVH Evaluation

Standard NVH testing procedures are designed to ensure consistent and repeatable results. These procedures often involve controlled environments and specific measurement techniques to isolate and quantify the various noise and vibration sources. They are essential for comparing performance across different prototypes or designs. The procedures typically encompass a set of protocols that detail specific steps, equipment, and measurement parameters for evaluating the NVH characteristics.

Setup and Configuration of Testing Environments

Proper setup and configuration of the testing environment is critical for accurate NVH data collection. This includes controlling factors such as temperature, humidity, and acoustic isolation to minimize external influences on the test results. A dedicated testing space with appropriate acoustic damping and vibration isolation is often required to obtain reliable data. Careful consideration must be given to the selection of test equipment and its calibration to ensure accurate and precise measurements.

NVH analysis is crucial for any vehicle, but it’s particularly important in electric vehicles (EVs). Recent EV reviews, like those found at EV reviews , often highlight how quiet operation, a key aspect of NVH, affects the overall driving experience. Ultimately, a good NVH analysis ensures a comfortable and satisfying ride for the driver and passengers.

The test environment must be carefully documented to ensure repeatability.

Importance of Environmental Controls During NVH Testing

Environmental controls are paramount for obtaining accurate and reliable NVH data. Factors like temperature, humidity, and ambient noise levels can significantly affect the results. For example, temperature fluctuations can alter material properties, impacting the perceived noise levels. Maintaining consistent environmental conditions throughout the testing process ensures that observed differences in NVH characteristics are truly attributable to the product under evaluation and not to external factors.

A precise and stable environment is essential for drawing accurate conclusions from NVH testing.

Examples of Specific NVH Testing Protocols

Different NVH testing protocols exist for various applications. For example, protocols for evaluating road noise in automobiles might involve specific driving cycles and measurement locations. Testing the interior noise of a car cabin often includes simulating different driving conditions and external noise sources. These protocols are meticulously designed to mimic real-world conditions, ensuring that the results are applicable to the intended use.

Steps Involved in Conducting a Typical NVH Test

Consistent procedures are essential for obtaining repeatable results. Following a standardized set of steps ensures that every test is conducted in the same manner, leading to reliable comparisons. The steps involved vary based on the specific test being conducted but generally follow a pattern.

| Step | Description |

|---|---|

| 1 | Prepare the test article and ensure all necessary equipment is calibrated and functional. |

| 2 | Set up the test environment according to the specified protocol, ensuring environmental controls are within acceptable limits. |

| 3 | Conduct the test according to the prescribed procedures, documenting all parameters and observations. |

| 4 | Analyze the collected data to identify any significant noise and vibration issues. |

| 5 | Document the results, including any observations, measurements, and analysis. |

NVH Analysis Case Studies

Case studies provide invaluable insights into the practical application of NVH analysis techniques. They demonstrate how these techniques can be utilized to identify and address noise, vibration, and harshness (NVH) issues in real-world product development scenarios. This section will present a detailed case study highlighting a successful NVH analysis project, exploring the challenges, solutions, and key takeaways.

Successful NVH Analysis Project: Reducing Engine Vibration in a Compact SUV

This case study focuses on a project aimed at reducing engine vibration in a new compact sport utility vehicle (SUV). Initial customer feedback indicated excessive engine vibration at low speeds, impacting the overall driving experience.

Challenges Faced

Several challenges were encountered during the NVH analysis. A primary concern was isolating the source of the vibration, given the complexity of the engine assembly and interactions with the vehicle’s chassis. Additionally, the project timeline was tight, necessitating efficient analysis methods.

Addressing the Challenges, NVH analysis

A multi-faceted approach was adopted. First, detailed measurements of engine vibration were taken at various points throughout the engine assembly, using accelerometers. These measurements were then correlated with engine operating parameters (RPM, load). Advanced finite element analysis (FEA) software, coupled with experimental modal analysis, helped to pinpoint the source of the vibration to a specific component within the engine mount assembly.

Materials, Processes, and Software Used

The project employed a range of materials, processes, and software. The engine mount assembly was primarily constructed from aluminum alloys. The NVH analysis utilized a combination of simulation tools like ANSYS and Abaqus for FEA. Sound and vibration measurement equipment from Brüel & Kjær was used to collect data.

Key Takeaways

The successful resolution of the engine vibration issue yielded several key takeaways. Early implementation of NVH analysis, alongside the utilization of advanced simulation software, proved crucial in identifying the root cause and developing effective countermeasures. Furthermore, the close collaboration between the design, engineering, and testing teams was essential for the project’s success. A significant cost savings was achieved by avoiding costly late-stage design changes.

Improved Product Quality

The project resulted in a noticeable reduction in engine vibration, leading to a significant improvement in the overall driving experience. Customer feedback surveys indicated a marked increase in satisfaction with the vehicle’s NVH characteristics. This success demonstrates the crucial role of NVH analysis in ensuring high-quality products and enhancing customer satisfaction.

Future Trends in NVH Analysis

The field of NVH (Noise, Vibration, and Harshness) analysis is constantly evolving, driven by advancements in technology and the increasing demand for quieter, smoother, and more comfortable products. Emerging trends are reshaping how NVH issues are identified, analyzed, and ultimately mitigated, leading to significant improvements in product design.The application of advanced technologies, particularly artificial intelligence (AI) and machine learning (ML), is transforming NVH analysis, offering new opportunities for predictive modeling and optimization.

This shift enables engineers to anticipate and address NVH problems earlier in the design process, leading to more efficient and cost-effective solutions.

Emerging Techniques in NVH Analysis

Advanced computational methods, such as finite element analysis (FEA) coupled with AI algorithms, are revolutionizing NVH analysis. These techniques can simulate complex interactions within a vehicle’s structure, predict NVH behavior under various operating conditions, and identify critical design parameters influencing NVH performance. This shift allows for virtual prototyping and testing, reducing the reliance on physical prototypes and accelerating the design cycle.

Role of AI and Machine Learning

AI and machine learning are playing a crucial role in enhancing NVH analysis by enabling predictive modeling, pattern recognition, and optimization. Algorithms can be trained on vast datasets of NVH data from various sources, enabling the identification of complex relationships between design parameters and NVH characteristics. This capability allows for the prediction of NVH behavior under different operating conditions and the optimization of design choices for improved performance.

Examples of Impact

One example is the use of AI in predicting the NVH characteristics of a vehicle during various driving conditions, allowing engineers to identify potential issues early in the design process. Another example involves the use of machine learning algorithms to identify patterns in historical NVH data, enabling engineers to predict potential NVH problems in new designs. These applications lead to a more proactive and preventative approach to NVH management, potentially leading to more cost-effective and efficient solutions.

Future Challenges and Opportunities

A key challenge is the need for substantial amounts of high-quality NVH data to train AI and machine learning models. Ensuring the availability and accessibility of such data is crucial for successful implementation. Another challenge is the need for engineers to develop the skills necessary to effectively use and interpret the results generated by these advanced techniques. The field offers a multitude of opportunities for researchers to develop new algorithms and models, as well as to explore novel applications of AI and machine learning in NVH analysis.

Potential Research Areas

Several promising research areas include developing more robust and accurate AI models for NVH prediction, exploring the integration of AI with other engineering tools, and investigating the use of AI for real-time NVH monitoring and control. Furthermore, research into the development of more sophisticated algorithms that can effectively handle large and complex datasets of NVH data is also a critical area for future research.

NVH Analysis in Different Industries

NVH analysis, encompassing noise, vibration, and harshness, is crucial for product development across diverse sectors. Understanding and mitigating NVH issues directly impacts customer satisfaction and product longevity. This section explores the specific applications of NVH analysis in various industries, highlighting the nuances and importance of tailored approaches.

NVH Analysis in the Automotive Industry

The automotive industry places significant emphasis on NVH performance. Passenger comfort and vehicle durability are directly linked to minimizing unwanted noise, vibrations, and harshness. NVH analysis in automobiles encompasses engine noise, transmission vibrations, tire-road interactions, and interior cabin noise. Precise measurements and simulations are critical for identifying and resolving these issues. Advanced modeling techniques, such as finite element analysis (FEA), are frequently used to predict and optimize NVH characteristics throughout the design process.

For example, the acoustic treatment of a vehicle’s interior can significantly reduce cabin noise, improving the passenger experience.

NVH Analysis in Aerospace

In the aerospace sector, NVH analysis is critical for ensuring aircraft safety and passenger comfort. Noise levels from engines and airframe components are a major concern. NVH analysis aids in the reduction of these levels to meet stringent regulatory requirements and improve the overall flight experience. Examples include analyzing the sound generated by jet engines, optimizing the design of airframe components to minimize vibrations, and improving the interior cabin acoustic design.

Furthermore, NVH analysis is essential for the development of quieter and more fuel-efficient aircraft. This requires a comprehensive understanding of the various sources of noise and vibration, enabling engineers to tailor their design solutions to minimize these factors.

NVH Analysis in Consumer Electronics

Consumer electronics, including smartphones, laptops, and home appliances, demand excellent NVH performance for user experience. Reducing noise and vibrations is crucial for a smooth user interface and enhanced product quality. NVH analysis is employed to ensure quiet operation, reduce the impact of mechanical components, and enhance the user experience. For example, the noise generated by a computer’s hard drive or the vibration of a smartphone’s internal components must be minimized for a seamless and quiet operation.

Advanced signal processing techniques and experimental methods are crucial for capturing and analyzing the subtle nuances of noise and vibration in these complex systems.

Comparison and Contrast of NVH Analysis Requirements Across Industries

While the fundamental principles of NVH analysis remain consistent across industries, the specific requirements and methodologies differ significantly. The automotive industry prioritizes overall vehicle comfort and durability, while the aerospace industry emphasizes safety and compliance with regulations. Consumer electronics focus on user experience and product aesthetics, demanding precise and repeatable measurements. The table below summarizes these differences.

Table: NVH Challenges and Solutions for Different Sectors

| Industry | Specific NVH Challenges | Common Solutions |

|---|---|---|

| Automotive | Engine noise, tire noise, interior cabin noise, vibration from components | Engine acoustic design, suspension system optimization, sound absorption materials, active noise cancellation |

| Aerospace | Engine noise, airframe vibrations, cabin noise, high-frequency vibrations | Engine design improvements, airframe structural optimization, advanced noise cancellation techniques, careful material selection |

| Consumer Electronics | Mechanical component noise, fan noise, vibration from moving parts | Optimized component design, noise dampening materials, careful component selection, use of quiet fans |

Conclusion

In conclusion, NVH analysis is a multifaceted process essential for enhancing product quality and user satisfaction. This guide has provided a detailed overview, equipping readers with the knowledge to approach NVH analysis effectively. From understanding the fundamental concepts to applying advanced techniques, this guide provides a solid foundation for navigating the complexities of NVH analysis.

Clarifying Questions

What are the common types of NVH issues?

Common NVH issues include engine noise, tire noise, body panel resonance, and interior noise. These issues can vary based on the product and industry.

What software is commonly used for NVH analysis?

Various software tools are used, including ANSYS, LMS Virtual.Lab, and Abaqus. The selection depends on the specific needs and industry.

What is the role of simulations in NVH analysis?

Simulations play a significant role in predicting and analyzing NVH characteristics before physical testing. They help optimize designs and identify potential issues.

How does NVH analysis support material selection?

NVH analysis helps determine the suitability of materials by evaluating their vibrational and acoustic properties. This allows for the selection of materials that effectively reduce NVH issues.