Hydrogen long-haul trucks represent a significant advancement in transportation, promising a cleaner and more efficient future for logistics. This innovative technology leverages hydrogen fuel cells to power massive vehicles, potentially revolutionizing long-distance trucking. Early adoption will require careful consideration of technical specifications, infrastructure development, and economic viability, but the long-term implications for supply chains and the environment are considerable.

This detailed exploration dives into the intricacies of hydrogen fuel cell technology, evaluating its potential for long-haul trucking. From technical specifications and design considerations to the crucial role of infrastructure development and environmental impact, this comprehensive overview examines every facet of this transformative technology. We’ll analyze the current state of the market, the challenges faced, and the potential for widespread adoption.

Introduction to Hydrogen Long-Haul Trucks

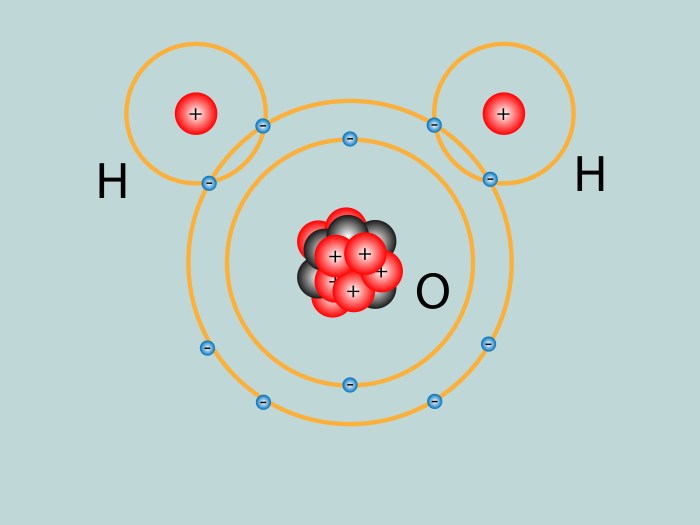

Hydrogen fuel cell technology, a promising alternative to traditional internal combustion engines, offers a potential solution for reducing emissions in the transportation sector. This technology converts hydrogen and oxygen into electricity to power vehicles, producing only water vapor as a byproduct. This makes it an attractive option for long-haul trucking, a sector heavily reliant on diesel fuel and contributing significantly to air pollution.Hydrogen-powered long-haul trucks have the potential to significantly reduce carbon emissions, but also present challenges related to infrastructure, cost, and safety.

The current state of hydrogen infrastructure development is crucial to the widespread adoption of this technology. Government policies and incentives play a vital role in fostering the necessary support for hydrogen fuel cell technology. The overall impact on logistics and supply chains will depend on the rate of adoption and infrastructure development.

Hydrogen Fuel Cell Technology in Transportation

Hydrogen fuel cell technology harnesses the chemical energy stored in hydrogen to generate electricity. This electricity powers an electric motor, eliminating the need for combustion and dramatically reducing emissions. Fuel cells offer the potential for high efficiency and low noise levels, making them suitable for various transportation applications, including long-haul trucks.

Potential Advantages of Hydrogen-Powered Trucks

Hydrogen-powered trucks offer several potential advantages over traditional diesel-powered trucks. They can achieve significant reductions in greenhouse gas emissions, contributing to a cleaner environment. Their potential for longer driving ranges and faster refueling times could improve operational efficiency and reduce downtime. The potential for quieter operation, reducing noise pollution in areas near transportation routes, is another significant benefit.

Potential Disadvantages of Hydrogen-Powered Trucks

Despite the advantages, hydrogen-powered trucks face challenges. The cost of hydrogen production, storage, and distribution is currently higher than that of diesel fuel. The infrastructure for hydrogen refueling stations is still underdeveloped compared to the existing network of diesel fuel stations. Safety concerns related to hydrogen storage and handling must be addressed to ensure public safety.

Current State of Hydrogen Infrastructure Development

The global infrastructure for hydrogen refueling is still in its early stages of development. A limited number of hydrogen refueling stations are currently operational in various parts of the world. The geographic distribution of these stations is uneven, presenting a challenge for widespread adoption. However, significant investments and government initiatives are driving the development of hydrogen infrastructure, paving the way for future expansion.

Role of Government Policies and Incentives

Government policies and incentives are crucial for promoting the adoption of hydrogen fuel cell technology. Financial incentives, such as tax credits or subsidies for hydrogen vehicles and infrastructure, can encourage investment and accelerate the transition. Regulations and standards for hydrogen safety and infrastructure development will ensure responsible and safe implementation. Government support is critical for driving innovation and market development.

Potential Impact on Logistics and Supply Chains

The adoption of hydrogen-powered trucks could reshape logistics and supply chains. The potential for improved operational efficiency, reduced emissions, and enhanced safety could significantly benefit the industry. However, the development and deployment of hydrogen infrastructure will be critical to the successful integration of these trucks into existing transportation networks. The logistics of sourcing and transporting hydrogen itself would also need to be addressed to create an efficient supply chain.

Technical Specifications and Design

Hydrogen fuel cell trucks represent a significant advancement in long-haul transportation, offering the potential for zero-emission operation. Crucially, realizing this potential requires careful consideration of the technical specifications and design elements. This section will delve into the key aspects of hydrogen fuel cell systems, including their integration into existing truck platforms, range limitations, refueling strategies, and the diverse materials used in their construction.

Fuel Cell System Specifications

Fuel cell systems for trucks typically utilize proton exchange membrane (PEM) technology. Key specifications include the power output, measured in kilowatts (kW), and the system’s voltage and current. Higher power outputs are needed for heavier trucks and steeper inclines. Furthermore, the system’s efficiency, expressed as the ratio of output power to input energy, plays a critical role in overall fuel economy.

Hydrogen long-haul trucks are definitely the future of transport, but the technology needs to mature. A crucial step in enhancing the driving experience for these vehicles is a reliable Bluetooth car adapter, like the one available here , to connect to various devices and improve overall driver convenience. This will be essential for the future success of hydrogen long-haul trucks.

Factors like temperature control and pressure management within the fuel cell stack are essential for optimal performance.

Integration into Existing Truck Platforms

Integrating hydrogen fuel cell systems into existing truck platforms requires careful engineering to maintain the truck’s structural integrity and operational functionality. Modifications may include the placement of fuel tanks, fuel cell stacks, and associated components, which need to be carefully designed for optimal space utilization and weight distribution. Additionally, the electrical system may require adjustments to accommodate the fuel cell’s output.

The challenge lies in balancing the addition of a complex system with the existing mechanical and electrical infrastructure of the truck.

Range and Refueling Challenges

A major hurdle in widespread adoption of hydrogen long-haul trucks is the current limitations in range and refueling infrastructure. Current hydrogen fuel cell systems, while advancing, still lag behind internal combustion engines in terms of achievable range. The size and weight of hydrogen tanks also impact the truck’s payload capacity. Refueling infrastructure is another critical issue, with the need for strategically located and readily accessible hydrogen fueling stations.

The speed of refueling is also a crucial factor in determining the overall efficiency of hydrogen-powered trucking operations.

Hydrogen Tank Materials and Storage Methods

The construction of hydrogen tanks is a crucial component of hydrogen fuel cell systems. High-pressure tanks made of advanced materials like carbon fiber composite are employed to ensure safety and structural integrity. The material selection and design considerations are critical in managing the high pressure of hydrogen storage. Various storage methods are being explored, including compressed hydrogen and liquid hydrogen.

Each method has its advantages and disadvantages regarding storage capacity, weight, and safety.

Compressed vs. Liquid Hydrogen

| Storage Method | Advantages | Disadvantages |

|---|---|---|

| Compressed Hydrogen | Relatively simpler and less expensive infrastructure for storage and transport. | Lower storage density compared to liquid hydrogen, resulting in larger tanks. |

| Liquid Hydrogen | Higher storage density, leading to potentially smaller tanks for a given amount of hydrogen. | Requires cryogenic storage and handling equipment, which increases the complexity and cost of infrastructure. |

The choice between compressed and liquid hydrogen depends on the specific requirements of the application, considering the balance between cost, efficiency, and safety. Factors like the availability of infrastructure, transportation needs, and the scale of the operation will influence the most suitable storage method.

Fuel Cell Efficiency and Performance

Hydrogen fuel cell technology holds significant promise for long-haul trucking, offering the potential for improved efficiency and reduced emissions compared to traditional internal combustion engines. However, realizing this potential requires a thorough understanding of fuel cell performance characteristics and the factors that influence their efficiency in real-world applications. This section delves into the key aspects of hydrogen fuel cell efficiency and performance in the context of long-haul trucking.

Energy Efficiency Compared to Internal Combustion Engines

Hydrogen fuel cells, in principle, offer higher energy efficiency than internal combustion engines (ICE) due to their electrochemical conversion process. This process avoids the thermodynamic losses inherent in combustion cycles. However, the overall system efficiency of a hydrogen fuel cell truck is influenced by factors like the efficiency of the hydrogen production, storage, and transport processes. Real-world testing has shown promising results, but further development is crucial to optimize the complete energy chain and minimize the overall energy loss from the hydrogen source to the truck’s wheels.

Factors Affecting Fuel Cell Performance in Long-Haul Trucks

Several factors can impact the performance of hydrogen fuel cells in the demanding conditions of long-haul trucking. These include:

- Operating Temperature: Fuel cell performance is highly temperature-dependent. Optimal performance typically occurs within a specific temperature range. Maintaining this range, particularly in extreme weather conditions, is crucial for consistent efficiency.

- Hydrogen Purity and Pressure: The quality of the hydrogen fuel directly impacts fuel cell performance. Impurities in the hydrogen stream can cause performance degradation. Maintaining appropriate pressure levels is also essential for efficient operation.

- Load Conditions: The varying load demands of long-haul trucks affect fuel cell operation. Dynamic load changes can introduce challenges in maintaining consistent power output and optimal performance.

- Electrolyte Degradation: Over time, the electrolyte membranes within the fuel cells can degrade, leading to reduced performance and efficiency. The degradation rate depends on factors such as temperature and operating conditions.

Monitoring and Optimizing Fuel Cell Performance

Monitoring and optimizing hydrogen fuel cell systems in long-haul trucks are essential for maintaining performance and reliability. Advanced diagnostic tools and control systems are crucial for this purpose.

- Real-time Monitoring: Sensors constantly monitor key parameters like current, voltage, temperature, and pressure within the fuel cell stack. This real-time data allows for immediate identification of potential issues and adjustments to operational parameters.

- Data Analysis: Collected data is analyzed to identify trends and patterns that can reveal performance degradation or areas for improvement. Predictive maintenance models can help anticipate potential failures and schedule maintenance proactively.

- Adaptive Control Systems: Sophisticated control systems adjust fuel cell operation based on real-time data and predicted conditions. This ensures optimal performance under varying operating conditions, maximizing energy efficiency.

Durability and Lifespan of Fuel Cell Components

The durability and lifespan of hydrogen fuel cell components significantly influence the long-term cost-effectiveness of this technology.

- Fuel Cell Stack Durability: The fuel cell stack, the core component, needs to withstand the rigors of long-haul operation, including temperature fluctuations, vibrations, and varying load demands. Manufacturers are continuously working to enhance the materials and designs for increased durability.

- Component Lifespan: The lifespan of different components, such as the membrane electrode assembly (MEA), bipolar plates, and other supporting components, varies. Accurate lifespan predictions are crucial for estimating total operational costs and planning maintenance schedules.

Operating Costs and Maintenance Needs

Understanding the operating costs and maintenance requirements is critical for assessing the economic viability of hydrogen fuel cell trucks.

| Cost Category | Description | Typical Costs (Estimated) |

|---|---|---|

| Fuel Costs | Cost of hydrogen fuel | Dependent on hydrogen production and delivery costs. |

| Maintenance | Routine maintenance and repair | Likely higher initially but could decrease with experience and optimized designs. |

| Electricity Consumption | Auxiliary power requirements | Can vary significantly based on the specific truck and system design. |

Note: Costs are estimates and may vary depending on specific implementation and market conditions. Reduced maintenance costs in the long term are anticipated as technology matures and reliability improves.

Infrastructure and Logistics

The viability of hydrogen-powered long-haul trucking hinges critically on the development of a robust infrastructure and logistics network. This includes not only hydrogen refueling stations but also a comprehensive supply chain for hydrogen production, transportation, and storage. Significant investment and planning are required to overcome existing challenges and establish a sustainable hydrogen ecosystem.

Current State of Hydrogen Refueling Stations

Currently, hydrogen refueling stations are relatively scarce, concentrated primarily in regions with significant industrial or research activity. These stations often serve specialized needs, such as supporting fuel cell vehicle testing or demonstrations. The limited availability necessitates a substantial expansion to support a long-haul trucking network. Geographic dispersion and the need for substantial hydrogen storage capacity are critical factors to consider.

Infrastructure Requirements for a Hydrogen Trucking Network

Establishing a robust hydrogen trucking network necessitates a strategic deployment of hydrogen refueling stations. Critical infrastructure considerations include:

- Location and Density: Stations need to be strategically placed along major trucking routes, considering the frequency and volume of traffic. Density should be sufficient to ensure minimal downtime for drivers, thus preventing significant delays.

- Hydrogen Storage Capacity: Sufficient storage capacity at each station is essential to meet the refueling demands of the trucks. Storage methods need to be safe and secure, considering the high energy density of hydrogen.

- Refueling Technology: Efficient and reliable refueling technology needs to be developed, ensuring rapid refueling times and safety standards.

- Supporting Infrastructure: This includes access to electricity for the operation of the hydrogen production and dispensing equipment.

Challenges of Establishing a Robust Hydrogen Supply Chain

Developing a sustainable hydrogen supply chain presents significant challenges:

- Hydrogen Production: Current hydrogen production methods often rely on fossil fuels, which reduces the environmental benefits of hydrogen vehicles. Transitioning to renewable hydrogen production methods (such as electrolysis using renewable energy sources) is crucial to achieve environmental goals. Examples of successful renewable hydrogen production projects, such as the use of solar or wind power, are important to study.

- Transportation and Storage: Hydrogen is a highly volatile substance requiring specialized transportation and storage methods. Current infrastructure for transporting and storing hydrogen in large quantities is not widespread. Technological advancements in efficient and safe hydrogen transport are needed to enable its long-haul distribution.

- Cost: The current cost of producing, transporting, and storing hydrogen is significantly higher than that of traditional fuels. Economic incentives and policies are necessary to reduce these costs and make hydrogen trucking competitive.

Logistics Considerations for Transporting and Storing Hydrogen

Several key logistics considerations are vital for a functional hydrogen supply chain:

- Transportation: Transporting hydrogen requires specialized vehicles and pipelines, which can be costly to implement. Regulations regarding hydrogen transport are needed to ensure safety and efficiency. Existing pipelines or transport networks for other substances could potentially be adapted to transport hydrogen.

- Storage: Hydrogen storage is a critical factor. Safe and efficient storage methods need to be developed for long-term storage, and cryogenic tanks or other advanced storage technologies need to be widely available.

- Safety: Hydrogen is flammable and requires careful handling and storage. Strict safety protocols and regulations are paramount to prevent accidents and ensure the safe operation of the entire hydrogen ecosystem.

Role of Hydrogen Production and Distribution in the Overall Ecosystem

The production and distribution of hydrogen are integral components of a hydrogen-powered transportation ecosystem. This includes the integration of hydrogen production facilities with the refueling network, optimizing hydrogen transport routes, and coordinating with other stakeholders. A coordinated approach to hydrogen production, transportation, and distribution is necessary to establish a robust hydrogen supply chain.

Economic Viability and Cost Analysis

The economic viability of hydrogen-powered long-haul trucks hinges on a complex interplay of factors, including fuel cell and hydrogen costs, operating expenses, and potential savings. Assessing the overall return on investment (ROI) for fleet operators is crucial in determining the long-term feasibility of this technology.The current market landscape presents both challenges and opportunities for hydrogen trucking. Fuel cell technology is still relatively nascent, leading to higher initial costs compared to established diesel counterparts.

However, ongoing advancements and economies of scale are expected to drive down these prices in the coming years. Understanding the cost dynamics is essential to evaluate the long-term economic benefits.

Current Market Prices for Hydrogen and Fuel Cells

Hydrogen production and distribution costs significantly influence the overall cost of operation. Currently, the price of hydrogen varies considerably depending on production methods and location. Electrolysis, a common method, requires substantial energy input, impacting the price. Alternative methods like reforming natural gas are more established but can introduce emissions. Similarly, fuel cell technology is still developing, leading to fluctuations in cost.

Companies are actively researching and developing more efficient and affordable fuel cells to drive down prices and enhance performance.

Operating Cost Comparison: Hydrogen vs. Diesel

Direct comparisons of operating costs between hydrogen and diesel trucks are complex, influenced by numerous factors. While the initial cost of hydrogen trucks might be higher, potential operating cost savings exist. Hydrogen fuel, when produced sustainably, can reduce emissions, potentially leading to lower taxes and regulations, and potentially higher resale value in the future. Fuel efficiency varies between different truck models and operating conditions.

The significant difference between hydrogen and diesel is that hydrogen trucks do not need to be refueled as frequently as diesel trucks, leading to reduced downtime and maintenance costs over time.

Potential Cost Savings and Return on Investment

Fleet operators can potentially realize cost savings through various avenues. Reduced maintenance costs associated with hydrogen engines, along with lower fuel consumption, can lead to significant savings over the truck’s lifecycle. Lower maintenance costs are due to the fewer moving parts in a hydrogen fuel cell compared to a diesel engine. The anticipated reduction in fuel costs, coupled with potential tax incentives or government support for clean transportation, further enhances the ROI.

Economic Benefits and Risks of Hydrogen Trucking

The economic benefits of hydrogen trucking include potential reductions in operating expenses, improved environmental performance, and enhanced brand reputation for fleet operators. This can attract environmentally conscious customers. However, significant risks remain, including the high initial investment costs for hydrogen infrastructure and the uncertainty surrounding hydrogen production and distribution scalability.

Potential Cost Comparison Table

| Truck Size | Distance (miles/day) | Estimated Hydrogen Cost (USD) | Estimated Diesel Cost (USD) | Potential Savings (USD) |

|---|---|---|---|---|

| Class 8 | 500 | 150 | 200 | 50 |

| Class 8 | 1000 | 300 | 400 | 100 |

| Class 8 | 1500 | 450 | 600 | 150 |

| Class 8 | 2000 | 600 | 800 | 200 |

Note: The above table provides estimated cost comparisons. Actual costs may vary based on specific factors such as fuel cell efficiency, hydrogen production methods, and local regulations.

Environmental Impact

Hydrogen-powered long-haul trucks offer a potential pathway to a cleaner transportation future. Evaluating the environmental impact necessitates a holistic view, considering the entire life cycle, from hydrogen production to the truck’s operation. A thorough assessment of greenhouse gas emissions, air quality, and noise pollution is crucial for a complete understanding.Assessing the environmental footprint of hydrogen-powered long-haul trucks requires a comprehensive life cycle analysis, encompassing the production, transportation, and utilization of hydrogen.

This evaluation provides a nuanced perspective, allowing for a comparison with conventional diesel-powered trucks.

Hydrogen long-haul trucks are a promising solution for sustainable freight transport. Securing these specialized vehicles often involves navigating complex financing options, and vehicle leasing platforms like vehicle leasing platforms can simplify the process considerably. This streamlined approach to acquiring hydrogen long-haul trucks can accelerate their adoption and help reduce emissions in the industry.

Greenhouse Gas Emissions Comparison

The environmental impact of hydrogen-powered trucks hinges significantly on the source of hydrogen. Green hydrogen, produced using renewable energy sources like solar or wind power, generates virtually zero greenhouse gas emissions during its production. Conversely, “grey” hydrogen, derived from natural gas with carbon capture and storage, still has a considerable carbon footprint, although less than diesel.

| Fuel Type | Greenhouse Gas Emissions (kg CO2e per km) |

|---|---|

| Diesel | Approximately 1.5-2.5 |

| Grey Hydrogen | Approximately 0.8-1.2 |

| Green Hydrogen | Near Zero |

Note: The figures for hydrogen are estimates and can vary significantly depending on the production process.

Comparing these figures reveals a considerable potential for emissions reduction when utilizing green hydrogen. Diesel trucks, on the other hand, remain a significant source of greenhouse gases.

Environmental Benefits of Hydrogen Fuel Cell Technology

Hydrogen fuel cell technology eliminates tailpipe emissions during operation. The process converts hydrogen and oxygen into electricity, with water as the only byproduct. This inherently cleaner combustion process significantly reduces local air pollution, enhancing the quality of air in urban areas and along transport routes.

Potential Impact on Air Quality and Noise Pollution

Hydrogen fuel cell vehicles produce only water vapor as a byproduct, leading to a substantial reduction in harmful pollutants like NOx and particulate matter compared to diesel engines. This results in improved air quality in areas heavily reliant on long-haul trucking.

Hydrogen fuel cell trucks generally exhibit lower noise levels compared to diesel trucks. This quieter operation can contribute to a more tranquil environment, especially in densely populated areas.

Life-Cycle Analysis of Hydrogen Production, Transportation, and Use

A complete life cycle assessment encompasses the entire process, from the source of energy for hydrogen production to the operation of the truck. The efficiency of hydrogen production, transportation, and storage significantly impacts the overall environmental impact. Optimizing these stages is crucial for minimizing the environmental footprint.

The development of efficient hydrogen storage and transportation infrastructure is critical to realizing the full environmental potential of hydrogen-powered long-haul trucks.

- Hydrogen Production: The environmental impact of hydrogen production is heavily dependent on the method used. Renewable energy sources are key for creating a truly sustainable hydrogen supply chain. Electrolysis powered by renewable energy sources, for example, significantly reduces the carbon footprint.

- Hydrogen Transportation: Efficient and safe transportation of hydrogen is essential. Current infrastructure for hydrogen transport is still under development, posing challenges for widespread adoption. Pipeline systems, cryogenic tankers, and other methods are being explored and tested.

- Hydrogen Use in Trucks: The efficiency of fuel cells and the durability of components in hydrogen-powered trucks are crucial factors. Ongoing research and development in these areas will play a vital role in reducing the cost and increasing the reliability of this technology.

Safety and Regulations: Hydrogen Long-haul Trucks

Hydrogen-powered long-haul trucks present unique safety challenges that require careful consideration. Robust safety protocols and stringent regulations are crucial to mitigate risks and ensure public safety, especially during storage, handling, and operation. Adherence to these standards is vital for the widespread adoption of this promising technology.The safety of hydrogen-powered trucks hinges on a multi-faceted approach. Comprehensive regulations must address the specific hazards associated with hydrogen, such as its flammability and potential for leaks.

This involves meticulous design, stringent testing procedures, and the development of effective safety protocols throughout the entire lifecycle of the vehicle.

Hydrogen Storage and Handling Safety

Safe hydrogen storage is paramount for minimizing risks. The chosen storage method significantly impacts safety. High-pressure tanks, for instance, require robust design and materials to prevent leaks and failures. Cryogenic storage, while offering higher energy density, demands specialized equipment and safety measures to prevent cold-related hazards. Regular inspections and maintenance are essential for all storage systems to ensure structural integrity and leak detection.

Operating Protocols for Hydrogen-Powered Trucks

Safe operating procedures are vital to prevent accidents. This includes training for drivers on handling hydrogen-powered trucks, emphasizing the importance of proper refueling procedures, avoiding ignition sources, and prompt response to leaks or emergencies. Drivers should be aware of the specific safety protocols for their vehicle model and be trained in emergency response procedures. This includes knowledge of proper shut-off procedures and emergency equipment use.

Regulations and Standards for Hydrogen Fuel Cell Vehicles

Regulations governing hydrogen fuel cell vehicles are evolving. International and national standards are crucial for establishing safety guidelines, ensuring interoperability between different systems, and fostering public trust. These standards encompass aspects like component testing, vehicle design, and emergency response protocols. The development and implementation of these regulations are essential for a smooth transition towards hydrogen-powered transportation.

Potential Risks and Hazards Associated with Hydrogen Use

Hydrogen’s flammability is a primary concern. A leak can quickly ignite, causing significant damage. Other potential hazards include hydrogen’s potential for explosion and the effects of hydrogen exposure. This necessitates the development of robust leak detection and containment systems. The risk assessment and mitigation strategies must be continuously reviewed and updated as the technology advances.

Safety Measures for Hydrogen Refueling Stations

Refueling stations are critical infrastructure for hydrogen-powered trucks. The safety measures implemented at these stations must be stringent. These stations should be equipped with advanced leak detection systems, explosion-proof equipment, and appropriate emergency response protocols. The design of refueling stations must incorporate measures to contain any hydrogen leaks and ensure safe access for personnel. Furthermore, the proximity of the station to residential areas and other sensitive locations needs to be carefully considered and addressed.

Emerging Technologies and Innovations

The hydrogen fuel cell sector is experiencing rapid advancements, driving innovation in areas crucial for long-haul trucking. These developments promise to enhance efficiency, safety, and cost-effectiveness, potentially accelerating the adoption of hydrogen-powered vehicles.This section details key emerging technologies and innovations, including advancements in hydrogen storage, transportation, fuel cell design, and associated research efforts. This analysis will also examine potential future trajectories for hydrogen long-haul trucking.

Advancements in Hydrogen Storage and Transportation

Efficient and safe hydrogen storage is a critical factor for the viability of hydrogen-powered vehicles. Significant research efforts are focused on improving storage density and reducing the associated risks.

- Compressed Hydrogen: High-pressure storage, while established, faces limitations in terms of energy efficiency and safety. Ongoing research aims to optimize compression technologies and develop advanced materials for stronger, lighter containers, reducing the risk of leaks and minimizing the weight penalty.

- Cryogenic Hydrogen: Storing hydrogen at extremely low temperatures (around -253°C) offers the potential for higher storage density. Challenges include maintaining cryogenic temperatures, which requires specialized insulation and transport systems, but the potential for higher efficiency and storage density remains a strong area of development. Examples like specialized tanks and pipelines are key elements of this approach.

- Chemical Hydrogen Carriers: These innovative approaches utilize chemical compounds to store hydrogen, potentially offering higher storage density than current methods. Examples include metal hydrides and complex ammonia systems, but significant hurdles in terms of cost-effectiveness, safety, and hydrogen release rate remain to be overcome. The potential for a breakthrough in this area would dramatically impact hydrogen transportation and storage.

Advancements in Fuel Cell Technology

Improvements in fuel cell technology are vital for enhanced performance and reduced costs. These advancements are crucial for long-haul trucking applications.

- Polymer Electrolyte Membrane (PEM) Fuel Cells: Research continues to improve the performance, durability, and cost-effectiveness of PEM fuel cells. Improvements in catalyst materials and membrane designs are driving increased efficiency and reduced operating temperatures. This will allow for greater reliability and long-term use.

- Solid Oxide Fuel Cells (SOFCs): SOFCs operate at higher temperatures, potentially offering higher efficiency and lower costs than PEMFCs. However, their implementation faces challenges related to materials compatibility and thermal management in a trucking application. Current research and development activities seek to resolve these hurdles.

- Fuel Cell Stack Integration: The development of more compact and efficient fuel cell stacks is critical for integrating them into truck designs. Innovations in stack design and manufacturing processes aim to optimize power density and reduce weight. The integration of stacks into the vehicle structure, maximizing space utilization and efficiency, is an important area of study.

New Designs and Applications for Hydrogen Fuel Cells in Trucks

New truck designs are incorporating hydrogen fuel cell technology, optimizing performance and integration.

- Electric-Powered Drive Systems: Fuel cell systems are often integrated with electric drive systems, offering the potential for improved acceleration, torque, and efficiency. This approach leverages the strengths of both technologies.

- Modular Design: Modular designs for fuel cell systems can allow for greater flexibility in the design and operation of trucks. This flexibility enables the incorporation of various hydrogen storage technologies and allows for adaptation to different operational requirements.

- Integration with Existing Infrastructure: Design efforts consider the infrastructure requirements for hydrogen production, storage, and distribution. Future hydrogen fueling stations should integrate seamlessly with the existing infrastructure for a smooth transition.

Research and Development Activities

Significant research and development efforts are ongoing across the globe to support hydrogen fuel cell technology for trucks.

- Government Funding and Initiatives: Governments worldwide are investing in research and development projects focused on hydrogen technologies, including those for long-haul trucking. This investment reflects a recognition of the potential of hydrogen-powered vehicles in transportation.

- Industry Collaboration: Collaboration between automotive manufacturers, fuel cell developers, and infrastructure providers is crucial for accelerating the development and deployment of hydrogen-powered vehicles. This collaborative effort is essential for achieving the goals of hydrogen long-haul trucking.

- Academic Research: Universities and research institutions are actively involved in exploring innovative solutions for hydrogen storage, transportation, and fuel cell technology. These research activities provide valuable insights and drive the development of new solutions.

Potential Future Directions for Hydrogen Long-Haul Trucking

The future of hydrogen long-haul trucking depends on the convergence of several key factors.

- Cost Reduction: Reducing the cost of hydrogen production, storage, and transportation is essential for widespread adoption. Economic viability is a critical factor for the long-term success of hydrogen fuel cell technology.

- Infrastructure Development: The expansion of hydrogen refueling infrastructure is crucial for enabling long-haul trucking operations. A comprehensive hydrogen refueling network will be necessary for wide-scale adoption.

- Performance Improvement: Ongoing research and development efforts aim to improve the performance and reliability of hydrogen fuel cell systems. Continuous improvements in fuel cell efficiency are critical for enhanced operational performance.

Public Perception and Adoption

Public perception plays a crucial role in the widespread adoption of hydrogen fuel cell technology for long-haul trucks. Understanding public concerns and fostering positive attitudes are vital for successful implementation. This section examines public perceptions, influencing factors, adoption strategies, and successful initiatives.

Public Concerns Regarding Hydrogen Technology

Public perception of hydrogen fuel cell technology is often shaped by factors like its novelty and perceived complexity. Concerns surrounding safety, infrastructure availability, and the overall environmental impact are frequently voiced. Public awareness campaigns can help address these concerns.

Factors Influencing Public Acceptance

Several factors influence public acceptance of hydrogen-powered trucks. These include the perceived reliability and safety of the technology, the availability of hydrogen refueling infrastructure, and the economic viability of hydrogen-powered vehicles compared to traditional diesel options. Addressing public safety concerns, such as potential hydrogen leakage, is crucial for fostering trust.

Strategies for Promoting Hydrogen Truck Adoption

Effective strategies for promoting hydrogen truck adoption include transparent communication about the technology’s benefits and addressing safety concerns. Highlighting the positive environmental impact, reduced emissions, and potential job creation opportunities associated with the transition can encourage wider acceptance. Collaborations between industry stakeholders, government agencies, and educational institutions are also essential for driving public awareness.

Successful Pilot Programs and Initiatives

Several pilot programs and initiatives have demonstrated the feasibility of hydrogen fuel cell technology for long-haul trucks. Examples include projects involving fleet trials in specific regions, demonstrating the practical application of hydrogen-powered trucks and their performance characteristics. These programs often involve collaboration between trucking companies, fuel cell manufacturers, and governmental organizations, fostering public trust and knowledge about the technology.

Public Awareness Campaigns and Educational Initiatives, Hydrogen long-haul trucks

Public awareness campaigns play a vital role in educating the public about the benefits and safety aspects of hydrogen fuel cell technology. These campaigns should use various channels, such as social media, presentations at community events, and partnerships with relevant organizations, to disseminate information effectively. Engaging with stakeholders through workshops, forums, and online platforms can further promote understanding and acceptance.

Case Studies and Examples

Hydrogen-powered long-haul trucking is still emerging, but several companies are actively exploring and implementing this technology. Early adopters and pilot programs are offering valuable insights into the challenges and opportunities of this transition. Analyzing these case studies helps us understand the practical implications and potential for widespread adoption.

Companies Involved in Hydrogen Long-Haul Trucking

Several companies are pioneering the development and deployment of hydrogen-powered long-haul trucks. These companies are not just experimenting; they’re actively investing in infrastructure, testing vehicles, and collaborating with logistics partners. This proactive approach is critical to the long-term viability of the technology.

- Toyota has been a prominent player in hydrogen fuel cell technology for years. Their involvement extends beyond passenger vehicles, with demonstrations of hydrogen-powered heavy-duty trucks, highlighting their commitment to the sector.

- Nikola, a prominent player in the hydrogen-powered trucking space, is actively developing and testing hydrogen fuel cell trucks. They’re working with logistics partners to identify suitable routes and demonstrate the practicality of hydrogen trucking.

- Daimler Trucks, a major player in the global trucking industry, is also exploring hydrogen fuel cell technology. Their involvement signifies the recognition of hydrogen’s potential to address the environmental concerns associated with traditional diesel-powered trucks.

Successful Deployments of Hydrogen-Powered Trucks

Early deployments of hydrogen-powered trucks often serve as pilot programs, focusing on specific routes and logistics partners. These deployments provide valuable data and insights into operational challenges and efficiencies. Key factors in successful deployments often include the availability of hydrogen refueling infrastructure and the alignment of truck usage with suitable routes.

- Several European companies have successfully tested hydrogen-powered trucks on long-haul routes, particularly in regions with established hydrogen infrastructure.

- Trials in North America, though fewer in number, are indicating that hydrogen fuel cell technology can meet the demands of specific long-haul routes, particularly for companies with existing long-haul operations.

- Successful deployments often involve close collaboration between trucking companies, fuel cell manufacturers, and infrastructure providers.

Challenges and Successes in Different Regions

The adoption of hydrogen fuel cell technology varies significantly across regions. Factors like infrastructure availability, regulatory frameworks, and the specific characteristics of trucking routes significantly influence the challenges and successes encountered. For instance, regions with existing hydrogen production facilities and supportive policies might experience faster adoption.

- Europe has demonstrated a more significant push towards hydrogen infrastructure development, leading to some successful deployments on specific routes, but the scale of operation is still limited.

- North America is experiencing growing interest, but challenges remain regarding the development of hydrogen infrastructure and the cost of hydrogen fuel cell technology.

- Asia is actively researching and investing in hydrogen fuel cell technology, although significant infrastructure development is needed before large-scale adoption.

Ideal Long-Haul Trucking Routes for Hydrogen Fuel Cell Technology

Certain long-haul trucking routes are better suited for hydrogen fuel cell technology than others. Routes with predictable mileage, sufficient time for refueling, and potential for minimizing idle time are key factors. The suitability of routes can also depend on the range of the hydrogen fuel cell truck.

- Routes with consistent distances between stops, allowing sufficient time for refueling, are well-suited.

- Routes with less frequent stops and higher mileage between refueling locations are ideal for optimizing the efficiency of hydrogen-powered trucks.

- Routes that are not highly dependent on specific geographical limitations regarding hydrogen infrastructure can potentially contribute to the early adoption of hydrogen fuel cell technology.

Case Study Outcomes

The following table provides a summary of case studies, highlighting the companies involved, their outcomes, and the regions where the deployments took place.

| Company | Outcome | Region |

|---|---|---|

| Toyota | Successfully tested hydrogen-powered trucks on designated routes, demonstrating feasibility. | Japan |

| Nikola | Pilot programs in various states in North America, with mixed results, including challenges with infrastructure. | North America |

| Daimler Trucks | Collaboration with partners in Europe on trials and testing of hydrogen trucks on specified routes. | Europe |

Comparison with Other Alternatives

Hydrogen-powered long-haul trucks are emerging as a compelling alternative to traditional diesel and other emerging technologies. A comprehensive evaluation necessitates a comparative analysis against existing and developing fuel sources, such as electric trucks and biofuels. This comparison assesses the strengths and weaknesses of each option, considering suitability for diverse routes and operational conditions.

Comparative Strengths and Weaknesses

Different alternative fuel options for long-haul trucks possess varying advantages and disadvantages. A careful consideration of these factors is critical in determining the optimal solution for specific applications.

- Electric Trucks: Electric trucks excel in terms of zero tailpipe emissions and quiet operation, but range anxiety and charging infrastructure limitations remain significant hurdles. The range of an electric truck is highly dependent on battery capacity, which translates to limited operating distances compared to traditional diesel trucks. Furthermore, the time required for charging can disrupt typical operational schedules, potentially affecting overall efficiency.

The high initial cost of electric trucks also poses a barrier to widespread adoption.

- Biofuels: Biofuels, like biodiesel and bioethanol, offer a pathway to reduced carbon emissions compared to fossil fuels. Their production can, however, have environmental implications, including land use changes and competition with food production. Furthermore, the performance and efficiency of biofuel-powered trucks can vary depending on the specific type of biofuel utilized. The cost of biofuels can also be highly variable and unpredictable, affecting the overall economic viability of this option.

- Hydrogen Fuel Cell Trucks: Hydrogen fuel cell trucks boast the potential for zero tailpipe emissions and high operational efficiency. The refueling time is shorter than that for battery charging in electric trucks. However, the current infrastructure for hydrogen refueling stations is limited, posing a challenge to widespread adoption. The high cost of hydrogen fuel cell technology is also a factor to consider.

Suitability for Different Routes and Conditions

The optimal alternative fuel option depends significantly on the specific characteristics of the trucking routes and conditions.

- Electric Trucks: Electric trucks are best suited for shorter routes with readily available charging stations. Their efficiency and performance are particularly well-suited to urban and suburban environments, where the limitations of range and charging infrastructure are less significant.

- Biofuels: Biofuels can be a viable option for longer routes if the production process is carefully managed and if the required infrastructure for handling and storage is already in place. Biofuel use is well-suited for specific types of freight and routes.

- Hydrogen Fuel Cell Trucks: Hydrogen fuel cell trucks are likely to be suitable for long-haul routes with limited charging infrastructure or where the frequency of stops is low. Their high efficiency and relatively fast refueling times make them a potentially strong option for these types of applications.

Factors Influencing Selection

Several key factors influence the selection of an alternative fuel option for long-haul trucking.

- Range: The operating range of the truck is crucial for long-haul operations. This directly impacts the required fuel capacity and charging/refueling infrastructure availability.

- Infrastructure: The availability of charging/refueling stations and related infrastructure is a critical determinant of operational feasibility.

- Cost: The cost of fuel, maintenance, and the vehicle itself plays a significant role in the economic viability of each alternative.

- Environmental Impact: The environmental footprint of each alternative is an increasingly important factor in the decision-making process.

Comparative Table

The following table summarizes the key characteristics of different alternative fuel options.

| Characteristic | Electric Trucks | Biofuels | Hydrogen Fuel Cell Trucks |

|---|---|---|---|

| Emissions | Zero tailpipe | Reduced, but variable | Zero tailpipe |

| Range | Limited by battery capacity | Variable | Potentially high |

| Refueling/Charging Time | Variable, slower than hydrogen | Variable | Faster than electric |

| Infrastructure | Requires charging stations | Requires handling and storage infrastructure | Requires hydrogen refueling stations |

| Cost | High initial cost, lower operating costs | Variable, potentially lower operating costs | High initial cost, variable operating costs |

End of Discussion

In conclusion, hydrogen long-haul trucks are a compelling prospect for a sustainable future in logistics. While challenges remain in infrastructure development and cost optimization, the potential environmental and economic benefits are substantial. Further research and development, coupled with supportive government policies, will be crucial to unlocking the full potential of this innovative technology. The future of long-haul trucking may well depend on the successful integration of hydrogen fuel cells into existing transportation networks.

FAQ Overview

What are the primary challenges in achieving sufficient range for hydrogen long-haul trucks?

Current hydrogen storage technologies limit the range of trucks due to the weight and volume of hydrogen required. Developing more efficient and compact storage methods is crucial for widespread adoption.

How do hydrogen fuel cells compare to traditional diesel engines in terms of operating costs?

While initial costs for hydrogen fuel cell systems might be higher, operational expenses, particularly fuel costs, could be lower, especially with declining hydrogen production costs.

What safety measures are in place for hydrogen refueling stations?

Safety protocols for hydrogen refueling stations include rigorous containment systems, strict handling procedures, and emergency response plans. Safety is paramount in handling this potentially explosive fuel.

What are the potential long-term economic benefits of hydrogen long-haul trucking for fleet operators?

Potential benefits include lower operating costs, reduced environmental impact, and potential for government incentives, ultimately leading to a greater return on investment.