Circular economy automotive is poised to revolutionize the industry, moving away from the traditional linear “take-make-dispose” model. This transformation prioritizes resource efficiency, material reuse, and reduced waste throughout the entire vehicle lifecycle. It’s a complex system, encompassing everything from material recovery and recycling to sustainable manufacturing processes and innovative mobility solutions. The transition to a circular economy is not just environmentally beneficial, but also presents significant economic opportunities and social advancements.

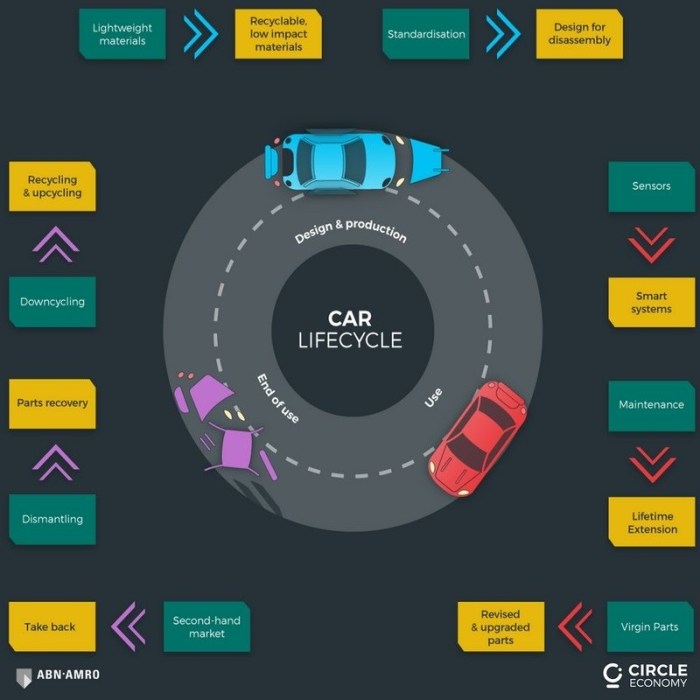

The circular economy automotive model tackles the environmental impact of the industry by addressing the entire lifecycle of a vehicle, from raw material sourcing to end-of-life management. This approach focuses on extending the lifespan of vehicles through innovative design, promoting the reuse and recycling of materials, and encouraging shared mobility options.

Introduction to Circular Economy in Automotive

The circular economy model represents a paradigm shift from the traditional linear “take-make-dispose” approach to manufacturing and consumption. It emphasizes resource efficiency, reuse, and recycling to minimize waste and maximize the value of materials throughout a product’s entire lifecycle. This approach is crucial for the automotive industry, which consumes vast quantities of raw materials and generates significant amounts of waste.The core principles of the circular economy in the automotive sector revolve around designing for durability, repairability, and recyclability.

This means incorporating materials that are easier to disassemble and reuse, and developing processes that allow for the recovery and reuse of components and materials at the end of a vehicle’s life. This contrasts sharply with the linear model, which often prioritizes single-use components and ends with significant waste generation.

Contrast Between Linear and Circular Economy Models

The linear economy model in the automotive industry typically involves extracting raw materials, manufacturing vehicles, selling them, and ultimately discarding them as waste. This process creates a significant environmental footprint and often results in material loss. Conversely, the circular economy model aims to keep materials and products in use for as long as possible. It involves designing products for disassembly, recycling, and reuse, aiming for zero waste and resource efficiency.

Successful Circular Economy Initiatives

Several automotive companies are pioneering circular economy initiatives. For example, some manufacturers are developing vehicles with modular designs that allow for easier component replacement and repair. Others are exploring innovative recycling technologies to recover valuable metals and materials from end-of-life vehicles. Furthermore, some companies are implementing take-back programs to facilitate the collection and recycling of vehicle components.

Product Lifecycle in a Circular Economy

This table illustrates the different stages of a product’s lifecycle within a circular economy approach for automobiles:

| Stage | Description | Circular Economy Focus |

|---|---|---|

| Extraction | Raw material sourcing | Prioritize recycled or renewable materials, minimizing the environmental impact of extraction. |

| Manufacturing | Vehicle assembly | Optimize material usage, employ durable and repairable designs, prioritize energy efficiency. |

| Use Phase | Vehicle operation | Design for longevity, enhance vehicle reliability, and promote vehicle maintenance. Encourage the sharing and rental of vehicles to reduce overall demand. |

| End-of-Life | Vehicle disposal | Implement comprehensive take-back programs, establish robust recycling processes, and recover valuable materials for reuse. |

| Recovery & Reuse | Recycling and remanufacturing | Ensure that valuable materials are recovered, recycled, and reused in new products. |

Material Recovery and Recycling

The transition to a circular economy in the automotive sector necessitates robust material recovery and recycling processes. Effective strategies for reclaiming valuable materials from end-of-life vehicles (ELVs) are crucial for resource conservation and reducing environmental impact. This involves not only the collection and processing of components but also the development of innovative technologies and infrastructure.Automotive materials vary widely in their composition and recyclability.

Some metals are easily recovered, while others, like certain plastics and composites, pose greater challenges. The successful implementation of recycling programs requires careful consideration of these complexities and the development of optimized procedures.

Methods for Material Recovery and Recycling of Automotive Components

Material recovery methods for automotive components encompass a range of approaches, each tailored to the specific material being processed. Mechanical processes, such as shredding and sorting, are frequently employed for initial material separation. Advanced techniques, including chemical processes, are sometimes necessary to extract valuable metals from complex alloys. The specific method used often depends on the type of component and the desired level of purity for the recovered materials.

The recovery process aims to maximize the yield of valuable materials and minimize the generation of waste.

Challenges and Opportunities Related to Recycling of Different Automotive Materials

Recycling different automotive materials presents distinct challenges and opportunities. Steel, a prevalent material in vehicles, is relatively straightforward to recycle, achieving high recovery rates. However, the intricate mix of metals in alloys and the presence of contaminants in various components can pose difficulties. Recycling aluminum, another common material, faces challenges related to the efficient separation from other materials.

Similarly, the recovery of plastics and composites is complex due to the diversity of polymers used and the potential for contamination. Opportunities lie in developing advanced separation technologies and promoting the use of recycled materials in new applications. For example, companies like BMW are pioneering the use of recycled aluminum and steel in new vehicles.

Current State of Automotive Recycling Infrastructure Globally

Globally, the automotive recycling infrastructure varies significantly. Developed nations often have more established and sophisticated facilities for processing ELVs, allowing for higher material recovery rates. Developing countries, however, often lack the necessary infrastructure, leading to lower recycling rates and environmental concerns. Investment in recycling facilities and the development of standardized procedures are crucial to improve global recycling rates and ensure the responsible management of automotive waste.

Comparison of Different Recycling Technologies and Their Effectiveness

Different recycling technologies for automotive materials offer varying degrees of effectiveness. Mechanical methods, such as shredding and sorting, are commonly used due to their cost-effectiveness and relative simplicity. Chemical processes, while potentially more effective in recovering specific materials, can be more expensive and energy-intensive. Pyrometallurgical processes, involving high temperatures, are suitable for certain metals, but often have environmental implications.

The optimal technology selection depends on factors such as the material composition, desired purity, and available infrastructure.

Recyclability of Various Automotive Materials

| Material | Recyclability | Challenges | Opportunities |

|---|---|---|---|

| Steel | High | Potential for contamination from other materials | Widely used in new vehicles, demonstrating high recovery rates. |

| Aluminum | Medium | Separation from other materials, potential for contamination | High value in the secondary market. |

| Copper | High | Potential for contamination from other materials | High demand in electrical applications. |

| Plastics | Low-Medium | Complexity in sorting and processing diverse types | Development of new processing technologies to enhance recovery rates. |

| Glass | High | Potential for contamination from other materials | Widely recyclable and reusable in new applications. |

| Rubber | Medium | Separation from other materials, potential for contamination | Potential for energy recovery and use in new applications. |

Design for Disassembly and Remanufacturing

Designing vehicles for ease of disassembly and subsequent remanufacturing is crucial for achieving a circular economy in the automotive industry. This approach minimizes waste, conserves resources, and reduces the environmental impact of vehicle production and disposal. By incorporating disassembly-friendly design principles, manufacturers can effectively recover valuable materials and components for reuse or recycling, contributing to a more sustainable future.Designing for disassembly is an iterative process that integrates the entire lifecycle of a vehicle, from initial design stages to eventual end-of-life management.

It necessitates a shift in perspective, moving away from a linear “make-use-dispose” model towards a more closed-loop system. This approach acknowledges the significant economic and environmental benefits associated with remanufacturing.

Designing for Disassembly

Designing for disassembly involves the careful consideration of how a vehicle can be broken down into its component parts efficiently and safely. This includes strategically placing fasteners, using standardized components, and ensuring accessibility for specialized tools and personnel. The goal is to facilitate rapid and accurate separation of parts, minimizing damage and maximizing material recovery. Proper labeling and documentation of components are equally important for efficient remanufacturing processes.

This includes creating detailed dismantling instructions for technicians.

Benefits of Design for Disassembly and Remanufacturing

The benefits of designing for disassembly and remanufacturing extend across various aspects of the automotive industry. These benefits include reducing material waste, conserving natural resources, and lowering production costs associated with new parts manufacturing. The use of recycled materials also contributes to the reduction of harmful emissions during manufacturing. This approach also enhances the lifespan of vehicles and parts, ultimately reducing the need for frequent replacements.

Circular economy automotive aims to reduce waste and maximize resource use. Adopting eco-driving techniques, like eco driving techniques , plays a crucial role in achieving this goal. By optimizing fuel efficiency and minimizing emissions, these techniques directly contribute to a more sustainable automotive sector.

Role of Modular Design

Modular design plays a vital role in enabling easier disassembly and remanufacturing. By dividing the vehicle into independent modules, manufacturers can facilitate the replacement or remanufacturing of specific components without impacting other parts of the vehicle. This modular approach allows for flexibility in design and maintenance, enhancing the vehicle’s overall lifespan. It also aids in the recovery of specific materials.

Remanufacturing Process

Remanufacturing involves refurbishing used automotive parts to restore them to their original condition. This process typically involves cleaning, inspecting, repairing, and testing the parts to ensure they meet the original specifications. The steps involved in the remanufacturing process include:

- Disassembly: Carefully separating the part into its constituent components.

- Cleaning: Thoroughly cleaning the parts to remove contaminants and debris.

- Inspection: Assessing the condition of each component and identifying any damage or wear.

- Repair/Replacement: Repairing or replacing damaged components with new or remanufactured parts.

- Testing: Rigorously testing the remanufactured part to verify its functionality and meet original specifications.

- Reassembly: Carefully assembling the remanufactured part to its original configuration.

Suitable Automotive Components for Remanufacturing

Remanufacturing can be applied to a wide range of automotive components. This approach is particularly effective for components that can be disassembled, cleaned, and repaired, allowing for cost savings and resource conservation. Below is a table outlining different types of automotive components suitable for remanufacturing:

| Component Type | Description |

|---|---|

| Engine Components | Crankshafts, cylinder heads, engine blocks, and other engine parts. |

| Transmission Components | Gearboxes, clutches, and other transmission parts. |

| Braking System Components | Brake calipers, brake pads, rotors, and other braking components. |

| Suspension Components | Shock absorbers, struts, and other suspension parts. |

| Electrical Components | Wiring harnesses, motors, and other electrical components. |

Extended Producer Responsibility (EPR)

Extended Producer Responsibility (EPR) is a policy framework that places a significant portion of the responsibility for end-of-life management of products on the producers themselves. This contrasts with traditional approaches where governments bear the primary burden for waste management. EPR aims to promote sustainability by encouraging producers to design for recyclability, reusability, and ultimately, a reduction in waste.EPR shifts the focus from a linear “take-make-dispose” model to a more circular one.

By holding producers accountable, EPR incentivizes them to consider the entire lifecycle of their products, from raw material sourcing to end-of-life disposal. This approach encourages innovation in sustainable materials, manufacturing processes, and product design.

Concept of EPR in the Automotive Industry

EPR in the automotive sector extends the producer’s responsibility beyond just the product itself. It encompasses the entire lifecycle, from the manufacturing process to the end-of-life management of vehicles. This includes the collection, sorting, recycling, and reuse of materials. Producers are required to contribute financially or technically to these processes.

Benefits of EPR for Circular Economy Principles

EPR policies, when effectively implemented, significantly contribute to the circular economy by:

- Incentivizing design for recyclability and reusability: Producers are motivated to incorporate recyclable and reusable materials into their designs, leading to a reduction in waste and a shift toward a more sustainable material mix.

- Enhancing material recovery and recycling rates: EPR programs often mandate or incentivize the collection and processing of end-of-life vehicles, improving the overall efficiency of material recovery and recycling streams.

- Promoting the development of sustainable materials and technologies: By placing responsibility on producers, EPR fosters innovation in the development of sustainable materials, manufacturing processes, and end-of-life technologies, such as advanced recycling techniques.

- Reducing environmental impact: A significant reduction in waste, improved resource efficiency, and decreased pollution are some direct outcomes of EPR policies, aligning with the fundamental principles of the circular economy.

Examples of EPR Policies in Various Countries

Numerous countries have implemented EPR policies for the automotive sector, with varying degrees of stringency and focus. Examples include:

- European Union: The EU has implemented several regulations that encompass the entire lifecycle of vehicles, from manufacturing to end-of-life management. These regulations often require manufacturers to pay for the end-of-life management of their vehicles.

- Japan: Japan has implemented policies that mandate the collection and recycling of end-of-life vehicles. The government works closely with manufacturers to ensure the effective implementation of these policies.

- South Korea: South Korea’s policies require manufacturers to take responsibility for the collection and recycling of end-of-life vehicles, aiming to improve resource efficiency.

Incentivizing Sustainable Materials and Processes

EPR policies can directly incentivize the development of sustainable materials and processes by:

- Setting targets for material recyclability: EPR policies can specify the percentage of recycled content required in new vehicles, thereby pushing producers toward more sustainable materials.

- Providing financial incentives for the development and implementation of new recycling technologies: EPR schemes can include provisions for funding research and development in advanced recycling methods, thus accelerating innovation.

- Encouraging the use of bio-based or recycled materials: Policies can offer financial or regulatory advantages to manufacturers using bio-based or recycled materials in their vehicle production, promoting sustainability and reducing dependence on virgin resources.

EPR Policies of Different Countries and their Impact (Illustrative Table)

| Country | EPR Policy Details | Impact (Illustrative) |

|---|---|---|

| European Union | Comprehensive regulations covering vehicle lifecycle, producer responsibility for end-of-life management. | Increased recycling rates, innovation in recycling technologies, shift toward more sustainable materials. |

| Japan | Mandates collection and recycling of end-of-life vehicles, collaboration with manufacturers. | Improved resource recovery, reduced environmental impact, potential for cost savings in material sourcing. |

| South Korea | Producer responsibility for collection and recycling of end-of-life vehicles. | Enhanced resource efficiency, reduced reliance on virgin materials, potential for job creation in recycling sector. |

Sharing Economy and Mobility Services

The sharing economy is rapidly transforming the automotive sector, offering new models of vehicle access and ownership. This shift is a crucial component of the circular economy, promoting resource efficiency and reducing the environmental impact of traditional car ownership. By enabling flexible mobility solutions, the sharing economy can play a vital role in transitioning to a sustainable transport system.The concept of shared mobility is not new, but the scale and scope of these services are rapidly expanding.

This dynamic environment presents both significant opportunities and challenges for the automotive industry, and understanding these facets is critical to fostering sustainable growth.

The Concept of the Sharing Economy in Automotive

The sharing economy, in the automotive context, refers to models that allow individuals to access vehicles without owning them. This includes car-sharing services, ride-hailing platforms, and peer-to-peer car rentals. These platforms connect drivers and passengers, promoting efficient use of vehicles and reducing the number of privately owned cars on the road. This concept directly aligns with the core principles of the circular economy by reducing the need for new vehicle production and extending the lifespan of existing vehicles.

Car-Sharing Programs and Circular Economy Principles

Car-sharing programs significantly contribute to a circular economy by optimizing vehicle utilization. Instead of each individual owning a car for infrequent use, car-sharing services allow many people to access vehicles on demand. This reduced need for individual ownership directly impacts the demand for new vehicle production, a critical element in a circular economy. Furthermore, optimized maintenance schedules and efficient repair procedures within the car-sharing fleet can extend the lifespan of vehicles.

These programs promote resource efficiency by reducing the overall number of vehicles needed and maximizing the use of existing resources.

Electric Vehicle (EV) Sharing Services and Circularity

The integration of electric vehicles (EVs) into sharing services is a powerful catalyst for circularity. EV batteries, while posing potential challenges regarding end-of-life management, offer opportunities for resource recovery and reuse. Recycling programs for EV batteries are already being developed and implemented, demonstrating the potential for a circular approach to handling these components. The potential for battery swaps or battery-as-a-service models further enhances the circularity of EVs in shared mobility programs.

Moreover, the reduced emissions from EVs in shared mobility networks contribute to overall environmental benefits.

Key Players in the Automotive Sharing Economy

The automotive sharing economy is characterized by a diverse range of key players, including:

- Automotive manufacturers: Manufacturers are increasingly developing and integrating car-sharing programs into their offerings, recognizing the shift in consumer preferences and the potential for new revenue streams. They are partnering with car-sharing companies to offer their vehicles, demonstrating a crucial role in the transition to shared mobility.

- Car-sharing companies: Companies like Zipcar, Getaround, and others are at the forefront of car-sharing services, developing platforms and infrastructure to connect drivers and passengers.

- Ride-hailing platforms: Companies like Uber and Lyft, while primarily focused on ride-hailing, are also expanding their services to include car-sharing options, demonstrating a growing convergence of services within the mobility sector.

- Technology companies: Companies like Google and Apple are contributing to the development of connected car technologies and mobile applications that facilitate car-sharing interactions.

Challenges and Opportunities for the Sharing Economy

The sharing economy in the automotive sector presents both challenges and opportunities. Challenges include:

- Infrastructure limitations: The availability of parking spaces, charging stations (especially for EVs), and other supporting infrastructure may limit the widespread adoption of sharing services.

- Regulatory hurdles: Regulations and licensing requirements for car-sharing programs can vary significantly across different regions, creating complexity and potential obstacles.

- Security concerns: Ensuring the security of vehicles and managing potential risks associated with shared access requires robust systems and protocols.

- Scalability issues: Scaling up car-sharing programs to meet growing demand can be challenging, requiring significant investment in infrastructure and operational capabilities.

Opportunities include:

- Increased vehicle utilization: Sharing services can significantly increase the utilization rate of vehicles, reducing the need for individual car ownership and minimizing the environmental footprint.

- Reduced traffic congestion: More efficient use of vehicles can potentially contribute to reduced traffic congestion in urban areas.

- New revenue streams for manufacturers: Manufacturers can generate new revenue streams through partnerships with car-sharing companies and access new market segments.

- Improved access to mobility for all: Shared mobility solutions offer convenient and affordable access to transportation, particularly for those who may not own a car or live in areas with limited public transport.

Sustainable Materials and Manufacturing

Moving towards a circular economy in the automotive industry necessitates a fundamental shift in material sourcing and manufacturing processes. Sustainable materials play a crucial role in reducing environmental impact, ensuring resource efficiency, and enhancing the overall lifecycle of vehicles. The focus on these materials reflects a growing global commitment to minimizing the industry’s carbon footprint and promoting responsible resource management.

Importance of Sustainable Materials

The automotive industry traditionally relies heavily on non-renewable resources. This dependence contributes significantly to resource depletion and environmental pollution. Employing sustainable materials in manufacturing offers a more environmentally friendly approach. The use of renewable and recycled materials reduces the strain on natural resources, lowers greenhouse gas emissions throughout the vehicle lifecycle, and decreases reliance on finite materials.

Sustainable materials also enhance the reputation of automotive companies, attracting environmentally conscious consumers and contributing to a more sustainable future for the industry.

Potential of Bio-Based Materials

Bio-based materials offer a promising alternative to conventional materials in automotive applications. These materials, derived from renewable resources like plants and agricultural byproducts, can replace petroleum-based components in various vehicle parts. Examples include bio-plastics for interior trim, body panels made from wood-based composites, and sustainable fabrics for seating. The potential for bio-based materials is substantial, as they can drastically reduce the environmental impact of vehicle production and contribute to a more circular economy.

Creating New Materials

The development of new materials for automotive applications is a continuous process. Research and innovation focus on creating materials with improved properties, enhanced performance, and reduced environmental impact. Advanced composites, reinforced polymers, and novel metals are being explored to improve fuel efficiency, structural integrity, and overall vehicle performance while minimizing environmental harm. These advancements often involve collaborations between automotive manufacturers, material scientists, and researchers.

Recycled Materials: Advantages and Disadvantages

Integrating recycled materials into vehicle manufacturing presents both advantages and disadvantages. Recycled materials offer a cost-effective alternative to virgin materials and contribute to waste reduction. Furthermore, utilizing recycled materials in automotive manufacturing can significantly decrease the environmental footprint of vehicle production. However, ensuring the quality and consistency of recycled materials can be challenging. The presence of impurities and the potential for variations in material properties can impact the performance and safety of the vehicle.

Strict quality control measures are necessary to mitigate these concerns.

Comparison of Sustainable Materials

| Material | Source | Properties | Advantages | Disadvantages |

|---|---|---|---|---|

| Recycled Steel | Scrap metal | Strong, durable | Cost-effective, reduces reliance on virgin ore | Potential for impurities, inconsistent quality |

| Bio-based Plastics | Plants, agricultural byproducts | Lightweight, potentially strong | Renewable resource, lower carbon footprint | May have lower strength compared to conventional plastics, limited availability |

| Recycled Aluminum | Scrap aluminum | Lightweight, recyclable | Resource-efficient, reduces energy consumption | Potential for impurities, processing challenges |

| Wood-based Composites | Wood fibers, resins | Lightweight, strong | Renewable resource, biodegradable | Potential for moisture absorption, limited availability in specific regions |

Energy Efficiency and Renewable Energy

The automotive industry’s transition to a circular economy hinges critically on minimizing its environmental impact, and energy efficiency and renewable energy play pivotal roles. Reducing energy consumption throughout the vehicle lifecycle, from manufacturing to operation, and embracing renewable sources are crucial steps in achieving sustainability.Efficient vehicles consume less energy, reducing the need for fuel and associated emissions, thereby lessening the environmental footprint.

Renewable energy sources offer a sustainable alternative to fossil fuels, minimizing reliance on finite resources and decreasing greenhouse gas emissions. These combined efforts contribute directly to a more sustainable and circular automotive ecosystem.

Energy Efficiency Improvements in Vehicles

Optimizing energy efficiency in vehicles is a multifaceted endeavor encompassing various technological advancements and design choices. Engine technologies play a key role, including advancements in internal combustion engines (ICE) and the burgeoning electric vehicle (EV) sector. Hybrid powertrains, for instance, combine ICEs with electric motors, allowing for improved fuel efficiency and reduced emissions.

Role of Renewable Energy Sources in the Automotive Sector

Renewable energy sources, such as solar and wind power, can significantly reduce the environmental impact of automotive manufacturing and operation. Utilizing renewable energy in vehicle production facilities minimizes reliance on fossil fuels and associated emissions. This transition is not only environmentally beneficial but also fosters economic opportunities.

Strategies for Improving Energy Efficiency in Vehicles

Several strategies contribute to enhancing energy efficiency in vehicles. Aerodynamic design, lightweight materials, and advanced engine technologies are key areas of focus. Optimized driving dynamics and advanced driver-assistance systems (ADAS) also contribute to reducing energy consumption.

- Aerodynamic Design: Streamlined vehicle shapes reduce air resistance, lowering energy consumption during operation. Examples include the use of spoilers and optimized underbody designs in production models.

- Lightweight Materials: Utilizing lighter materials in vehicle construction significantly reduces the mass that needs to be accelerated, lowering fuel consumption. Aluminum and carbon fiber composites are frequently employed in modern vehicle designs.

- Advanced Engine Technologies: Engine advancements, such as turbocharging and variable valve timing, enhance fuel efficiency. These technologies improve combustion and reduce energy loss in traditional ICEs.

- Optimized Driving Dynamics: Features such as regenerative braking systems, which recover energy during braking, and optimized gear ratios contribute to energy efficiency.

- Advanced Driver-Assistance Systems (ADAS): ADAS features like adaptive cruise control and lane-keeping assist can improve driving smoothness and reduce unnecessary acceleration and braking, leading to fuel savings.

Incorporating Renewable Energy Sources into Automotive Manufacturing

Transitioning to renewable energy sources in automotive manufacturing involves several methods. Solar panels and wind turbines can power production facilities, reducing reliance on the grid and minimizing emissions. Utilizing renewable energy for charging EV batteries is another crucial aspect of the transition.

- On-Site Renewable Energy Generation: Integrating solar panels and wind turbines on production sites reduces reliance on the grid and associated emissions. This is especially relevant for facilities with ample space and suitable conditions for these installations.

- Renewable Energy for Battery Charging: Utilizing renewable energy sources, such as solar or wind power, to charge electric vehicle batteries reduces the carbon footprint associated with electricity generation. This approach is vital for achieving a truly sustainable EV lifecycle.

Reducing the Environmental Footprint of Vehicle Production

Minimizing the environmental footprint of vehicle production is crucial. Reducing material waste, using recycled materials, and optimizing manufacturing processes are critical aspects.

- Material Recycling: Recycling materials like aluminum and steel reduces the demand for virgin resources and associated environmental impacts. Implementing robust recycling programs is essential for circularity.

- Optimized Manufacturing Processes: Optimizing manufacturing processes to minimize energy consumption and waste generation reduces the environmental impact of vehicle production. Continuous improvement methodologies are critical.

End-of-Life Vehicle Management

Effective end-of-life vehicle (ELV) management is crucial for a successful circular economy in the automotive sector. Properly managing vehicles at the end of their useful life minimizes environmental impact, conserves resources, and promotes responsible resource recovery. It also facilitates the transition towards a more sustainable and resilient automotive industry.ELV management encompasses a wide range of activities, from dismantling and recycling to the reuse of parts and the responsible disposal of hazardous materials.

A well-structured approach ensures the recovery of valuable materials, while minimizing pollution and the risk of environmental contamination.

Importance of Effective ELV Management

Effective ELV management is vital for several reasons. It minimizes environmental harm by reducing landfill waste and promoting the recovery of valuable materials like steel, aluminum, copper, and plastics. Furthermore, it safeguards human health by controlling the release of hazardous substances. It also helps in complying with regulations and maintaining a positive public image for automotive companies and the industry as a whole.

Methods for Managing ELVs within a Circular Economy Framework

Several methods are employed to manage ELVs within a circular economy framework. These methods are designed to maximize resource recovery and minimize environmental impact. Key strategies include dismantling vehicles, recovering reusable components, recycling materials, and treating hazardous substances. These strategies are designed to optimize the process, ensuring compliance with environmental regulations and contributing to the overall circular economy.

Challenges in Managing ELVs in Different Regions

Managing ELVs presents various challenges across different regions. These challenges stem from varying regulations, infrastructure limitations, economic factors, and cultural norms. Developing countries, for instance, often face issues with inadequate infrastructure for dismantling and recycling, leading to potential environmental risks. Developed countries, while having more advanced infrastructure, may encounter issues with the economic viability of recycling certain materials.

These diverse regional challenges underscore the need for adaptable and tailored ELV management strategies.

Methods to Promote Responsible Disposal of Vehicles

A structured approach to promoting responsible disposal is essential. This includes implementing comprehensive regulations, raising public awareness, and providing incentives for responsible practices. Vehicle owners should be educated on proper disposal methods and the importance of recycling. Incentives like tax breaks or financial reimbursements for the return of vehicles for recycling can encourage responsible practices. Government regulations should be in place to ensure the proper handling and disposal of ELVs.

Comparison of ELV Management Strategies

| Strategy | Description | Environmental Impact | Economic Viability |

|---|---|---|---|

| Disassembly and Recycling | Systematic dismantling of vehicles to recover reusable parts and recycle materials. | Minimizes landfill waste, recovers valuable resources. | Potentially high, dependent on material prices and processing efficiency. |

| Remanufacturing | Rehabilitation of used components to restore their original functionality. | Reduces material consumption and waste. | High, especially if demand is present for the remanufactured parts. |

| Reuse | Direct repurposing of vehicles or components for alternative applications. | Significant reduction in waste and resource consumption. | Variable, depends on the application and demand for used parts. |

| Landfilling | Disposal of vehicles in landfills. | High environmental impact, resource depletion. | Generally low, but can be cost-effective for certain situations. |

Policy and Regulatory Frameworks

Government policies and regulations play a crucial role in shaping the automotive industry’s transition towards a circular economy. These frameworks provide the necessary incentives and constraints to encourage sustainable practices, drive innovation, and ensure the responsible management of vehicles throughout their lifecycle. Effective policies can stimulate investment in recycling infrastructure, incentivize the design for disassembly, and ultimately create a more environmentally friendly automotive sector.The effectiveness of circular economy initiatives in the automotive sector hinges heavily on supportive policy environments.

Robust regulations can compel manufacturers to adopt sustainable practices, leading to a reduction in waste and environmental impact. These policies also foster a level playing field for businesses committed to circular economy principles, potentially accelerating the broader adoption of these practices across the industry.

Role of Government Policies

Government policies are instrumental in driving the circular economy in the automotive industry. These policies can establish targets for recycling rates, incentivize the development of sustainable materials, and mandate design for disassembly. They can also support the creation of a skilled workforce for recycling and remanufacturing processes. Ultimately, effective policies can unlock the full potential of the circular economy by providing the necessary framework for sustainable practices.

Importance of Regulations

Regulations are critical for ensuring the sustainability of the automotive industry. They establish clear standards for material usage, waste management, and end-of-life vehicle (ELV) handling. Robust regulations can prevent environmentally harmful practices and ensure that the transition to a circular economy is implemented responsibly and effectively. By enforcing regulations, governments can create a predictable and supportive environment for companies to invest in circular economy solutions.

Key Policies and Regulations Supporting Circular Economy Principles

- Extended Producer Responsibility (EPR) schemes: These policies hold manufacturers accountable for the end-of-life management of their products, encouraging them to design for recyclability and reuse. Manufacturers are incentivized to minimize environmental impact by incorporating recycled materials in their designs.

- Tax incentives and subsidies for sustainable materials and technologies: Governments can offer financial incentives to encourage the use of recycled materials and the development of innovative technologies for material recovery and recycling. This encourages businesses to adopt more sustainable production methods.

- Mandates for design for disassembly: These regulations require manufacturers to design vehicles in a way that facilitates disassembly and component recovery at the end of their lifespan. This increases the potential for reuse and recycling.

- Standards for material recovery and recycling: Setting clear standards for material recovery and recycling ensures that resources are effectively captured and reused. This minimizes waste and maximizes resource efficiency.

Challenges in Implementing Effective Policies

Implementing effective policies faces several challenges. Coordination among different government agencies and stakeholders can be difficult. The complexity of the automotive supply chain can make it challenging to implement policies effectively across all actors. Policymakers must also consider the potential economic impacts on different sectors and address any concerns about job displacement. The cost of implementing new regulations can be a hurdle, but these are offset by the long-term environmental and economic benefits.

Examples of Policy Initiatives in Different Countries

Several countries have implemented initiatives to promote circular economy principles in the automotive industry. For instance, some European countries have implemented comprehensive EPR schemes for ELVs, which have spurred advancements in vehicle recycling and reuse. These schemes have driven investment in recycling infrastructure and improved the overall sustainability of the automotive industry. Furthermore, certain countries have established incentives for the development and adoption of electric vehicles, aiming to reduce reliance on fossil fuels.

Economic and Societal Impacts: Circular Economy Automotive

The transition to a circular economy in the automotive sector presents a multifaceted opportunity to reshape the industry’s economic and societal footprint. By prioritizing resource efficiency, reuse, and recycling, the sector can unlock substantial economic benefits, create new job opportunities, and contribute to a more sustainable future. This shift necessitates a holistic approach encompassing design, manufacturing, and end-of-life management.The circular economy model offers a powerful pathway to enhance the automotive industry’s resilience and competitiveness by reducing dependence on finite resources.

This approach also enables a more sustainable consumption and production pattern, mitigating environmental risks and promoting long-term economic stability.

Circular economy principles are crucial in the automotive industry, particularly when considering the rise of electric vehicles like electric trucks. The focus on sustainable material sourcing and battery recycling is vital for the long-term viability of this transition. Ultimately, a truly circular economy approach is needed for the future of automotive manufacturing.

Economic Benefits of Implementing Circular Economy Principles

Implementing circular economy principles in the automotive industry yields a range of economic benefits. These range from cost savings through material recovery and reuse to the creation of new market opportunities. By embracing a lifecycle approach, the industry can optimize resource utilization, minimize waste generation, and unlock cost efficiencies.

- Reduced material costs: Recycling and reusing materials drastically reduce the need for virgin resources, lowering production costs and improving profitability. For example, companies using recycled aluminum in car components can experience significant savings compared to using raw aluminum.

- Enhanced product lifespan: Designing for durability and repairability extends the lifespan of vehicles, reducing the need for frequent replacements and increasing the overall value of the product. A longer product lifecycle can generate higher revenue streams over time.

- Creation of new markets and industries: The circular economy fosters the development of new markets and industries related to material recovery, recycling, and reuse. This creates opportunities for innovation and job creation in these specialized fields.

- Increased competitiveness: Companies that adopt circular economy principles demonstrate environmental responsibility and enhance their brand image. This often translates to increased customer loyalty and a competitive edge in the market.

Social Impacts of the Transition to a Circular Economy

The transition to a circular economy in the automotive sector has significant social implications, affecting employment, community development, and overall well-being.

- Job creation: The circular economy model fosters the development of new jobs in areas like material recovery, recycling, and remanufacturing. For instance, specialized technicians and engineers are needed for the disassembly and repair of vehicles. Furthermore, the increased demand for sustainable materials and manufacturing processes will create more opportunities for specialized workers.

- Community development: Circular economy initiatives can revitalize local communities by creating employment opportunities and fostering economic growth. This can lead to improved infrastructure and social services, benefiting the overall community.

- Improved worker safety: The transition towards safer and more efficient recycling and remanufacturing processes can contribute to improved working conditions and reduce risks associated with traditional end-of-life vehicle management.

Job Creation Potential Associated with Circular Economy Initiatives

Circular economy initiatives in the automotive sector offer significant job creation potential across various sectors.

- Recycling and material recovery: Specialized technicians, engineers, and workers are needed for sorting, processing, and recycling automotive components. This creates direct employment opportunities.

- Remanufacturing and repair: Skilled labor is required for disassembling, repairing, and remanufacturing parts, creating jobs in specialized workshops and facilities.

- Design and engineering: The need for designing vehicles for disassembly and reuse creates new roles for engineers and designers focused on circular economy principles.

- Sustainable materials manufacturing: The production of sustainable materials for vehicles will lead to new employment opportunities in manufacturing facilities focused on these specialized materials.

Potential for Reducing Waste and Pollution

Adopting circular economy principles significantly reduces waste and pollution associated with the automotive lifecycle.

- Minimized waste generation: By designing for disassembly and reuse, the industry can drastically reduce the amount of waste sent to landfills. This approach also lowers the consumption of raw materials.

- Reduced pollution: Recycling and remanufacturing processes generally produce less pollution than extracting virgin materials. This contributes to a cleaner environment and healthier communities.

- Improved resource efficiency: The circular economy model encourages the reuse and recycling of materials, improving resource efficiency and minimizing the environmental impact of the industry.

Long-Term Economic Impact

The long-term economic impact of adopting circular economy principles in the automotive industry is substantial and positive. It’s not just about short-term cost savings; it’s about building a resilient and sustainable industry for the future.

“A circular economy approach fosters long-term economic growth by creating a more sustainable and resilient industrial landscape.”

- Increased competitiveness: Companies embracing circular economy principles will enhance their long-term competitiveness by minimizing their environmental footprint and optimizing resource use.

- Enhanced resilience: A circular economy approach makes the automotive industry less vulnerable to fluctuations in raw material prices and supply chain disruptions.

- Sustainable growth: The industry can experience long-term, sustainable growth by prioritizing resource efficiency and minimizing environmental impact.

Future Trends and Innovations

The automotive sector is undergoing a rapid transformation, driven by the increasing adoption of circular economy principles. This evolution necessitates a proactive approach to embracing emerging technologies and innovative business models to foster sustainability and resource efficiency. The future of mobility is intricately linked to the effective implementation of circular economy principles, shaping not only the production and consumption of vehicles but also the entire lifecycle management.

Emerging Trends in Circularity

The circular economy in automotive is characterized by several emerging trends, including the increasing emphasis on vehicle reuse, refurbishment, and recycling. This shift is driven by the growing recognition of the environmental and economic benefits of extending the lifespan of vehicles and maximizing material recovery. Furthermore, innovative business models are being developed, focusing on shared mobility and vehicle-to-grid (V2G) technologies.

Potential of New Technologies

New technologies hold immense potential for promoting circularity in the automotive sector. Advanced materials, such as recycled plastics and metals, are being developed and integrated into vehicle production. This approach not only reduces the reliance on virgin materials but also lowers the environmental footprint of manufacturing. Additionally, advancements in battery technology, coupled with innovative energy storage solutions, are paving the way for more sustainable and efficient mobility.

Emerging Technologies Supporting Circularity

Several emerging technologies are poised to significantly support the circularity of the automotive sector. These include:

- Advanced Materials: The development of high-performance recycled materials like recycled plastics and metals is a crucial aspect. Companies are exploring various methods to recycle and reuse materials, reducing the need for new resource extraction. For example, Tesla’s use of recycled aluminum in their vehicles showcases the potential for sustainable material sourcing.

- Additive Manufacturing (3D Printing): This technology enables the production of complex parts using recycled materials, reducing waste and improving efficiency. It can also enable customized repairs and upgrades, extending the lifespan of vehicles.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms can optimize vehicle design for recyclability, predict potential material failures, and facilitate the automated sorting of materials during dismantling.

- Vehicle-to-Grid (V2G) technology: This technology enables vehicles to act as energy storage units, allowing them to feed electricity back into the grid. This can enhance energy efficiency and promote a more sustainable energy system.

Future of the Automotive Sector

The automotive sector will be significantly shaped by circular economy principles in the coming years. This shift will lead to more sustainable vehicle production, enhanced vehicle lifecycle management, and the development of innovative business models. The focus will be on designing vehicles for disassembly, remanufacturing, and reuse, creating a closed-loop system for materials. Examples of this are already emerging with companies like BMW and Renault exploring vehicle sharing programs, highlighting the transition toward circular models.

Technology-Enabled Circularity Table, Circular economy automotive

| Technology | Enabling Circularity | Example |

|---|---|---|

| Advanced Materials | Reduced reliance on virgin materials, lower environmental footprint | Recycled aluminum in vehicle construction |

| Additive Manufacturing | Customizable parts, reduced waste, extended vehicle lifespan | 3D-printed repair parts for existing vehicles |

| AI/ML | Optimized design for recyclability, automated dismantling | Predictive maintenance systems that identify potential material failures |

| V2G | Enhanced energy efficiency, sustainable energy system | Electric vehicles acting as energy storage units for the grid |

Last Word

In conclusion, the circular economy automotive approach represents a significant shift towards sustainability and resource efficiency. By implementing innovative strategies across the vehicle lifecycle, from material selection to end-of-life management, the industry can minimize its environmental footprint and create a more resilient and sustainable future. The transition will require collaboration among industry stakeholders, policymakers, and consumers, but the potential rewards are substantial.

Quick FAQs

What are the key challenges in implementing circular economy principles in the automotive sector?

Implementing circular economy principles in the automotive sector faces several challenges, including the high upfront investment costs for new technologies, the need for robust recycling infrastructure, and the potential for resistance from established industry players. There are also challenges in standardizing materials and processes for seamless material reuse.

How can governments incentivize the adoption of circular economy practices in the automotive industry?

Governments can incentivize circular economy adoption through policies like tax breaks for companies investing in recycling and remanufacturing technologies, subsidies for the development and deployment of sustainable materials, and regulations that promote the design for disassembly of vehicles. This can encourage the development of new, sustainable technologies and business models.

What role do consumers play in a circular economy automotive model?

Consumers play a crucial role in driving circular economy principles in the automotive sector. By choosing vehicles with a focus on durability, repairability, and recyclability, and by actively participating in shared mobility programs, consumers can directly influence the demand for sustainable products and practices.

What are the economic benefits of adopting a circular economy approach in the automotive sector?

The transition to a circular economy in the automotive sector creates economic opportunities through the development of new technologies, the creation of new jobs in recycling and remanufacturing, and the potential for cost savings associated with reduced material waste and increased resource efficiency.