Brake upgrades are a crucial aspect of vehicle maintenance, impacting safety and performance. This comprehensive guide explores various upgrade options, from rotors and pads to calipers, examining the factors to consider, installation procedures, and the resulting performance gains. We’ll delve into safety considerations, cost analysis, troubleshooting, and even environmental impact, providing a holistic view of this important automotive upgrade.

Choosing the right brake upgrade involves careful consideration of your vehicle type, driving style, and budget. Different upgrades offer varying performance levels and cost ranges. This guide will help you navigate the complexities of brake upgrades, ensuring you make informed decisions for your vehicle’s needs.

Brake Upgrades

Brake upgrades are a crucial aspect of vehicle maintenance and performance, significantly impacting safety and handling. They enhance the stopping power and responsiveness of a vehicle, contributing to a more controlled and confident driving experience. This is particularly important for high-performance vehicles, those used in challenging conditions, or for drivers seeking to improve their vehicle’s capability and safety.Brake upgrades involve replacing components of the braking system with improved parts.

This can lead to better stopping distances, reduced fade, and enhanced responsiveness, which can translate to a safer and more enjoyable driving experience. These upgrades are tailored to various needs and vehicle types, from daily commuters to enthusiasts looking to extract the maximum performance from their cars.

Types of Brake Upgrades

Brake upgrades encompass various component replacements, each offering specific advantages. These components are crucial to the overall braking system, and replacing them with improved parts can significantly enhance the performance and safety of a vehicle.

- Brake Rotors:

- Brake Pads:

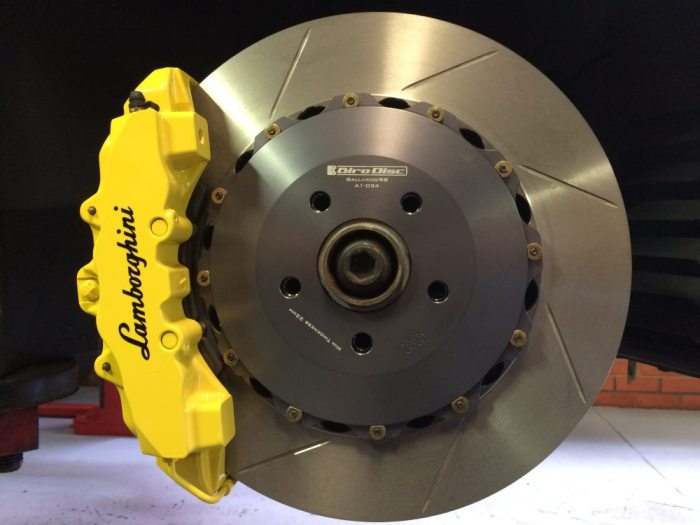

- Brake Calipers:

Brake rotors are essential components of the braking system. They are the metal discs that friction material (brake pads) rubs against to slow the vehicle. Upgraded rotors are typically made of stronger materials like high-carbon steel or ceramic composite, which can withstand higher temperatures and provide better heat dissipation. This results in improved braking performance, especially during sustained or high-performance braking.

For example, upgraded rotors can reduce brake fade, which is a common issue in high-performance vehicles, where prolonged braking can lead to a reduction in braking power.

Brake pads are the friction material that interacts with the brake rotors. Upgraded pads are formulated with materials optimized for specific conditions and performance levels. Different pad types exist, each with distinct properties and advantages. For instance, some pads are better at handling high temperatures, providing consistent braking performance even in demanding situations. Others are designed for quieter braking, a significant benefit for everyday drivers.

This factor affects both safety and the overall driving experience.

Brake calipers are the mechanical components that hold and apply the brake pads to the rotors. Upgraded calipers can have increased clamping force and improved piston design, contributing to a more powerful and consistent braking system. This can lead to quicker stopping distances and more controlled braking, especially important in emergency situations. An example is the use of larger calipers in high-performance vehicles to provide enhanced stopping power, which can be critical in high-speed situations.

Benefits of Brake Upgrades

Upgrading brakes offers significant advantages, impacting both safety and performance. The improvements directly translate to a safer and more capable vehicle, enhancing the driver’s control and confidence.

- Improved Stopping Power:

- Enhanced Safety:

- Increased Performance:

Upgraded brake components, like rotors, pads, and calipers, lead to a more powerful and consistent braking system. This improvement translates to shorter stopping distances and more controlled braking, which is crucial in emergency situations and everyday driving. For instance, upgrading to performance brake pads can drastically reduce stopping distances, particularly at higher speeds.

Better braking performance directly translates to improved safety. Shorter stopping distances and more consistent braking allow for quicker responses to unexpected situations, minimizing the risk of accidents. This factor is paramount, especially in high-speed scenarios or challenging driving conditions.

Brake upgrades are not just about safety; they also enhance performance. Improved stopping power can improve vehicle handling, particularly in high-performance driving scenarios. This enhanced control allows drivers to push their vehicle’s limits more safely and confidently. An example is the use of performance brakes in racing, where every fraction of a second counts.

Choosing the Right Upgrade

Selecting the right brake upgrade hinges on careful consideration of several factors. A poorly chosen upgrade might not improve stopping power, or worse, could compromise safety. Understanding your vehicle’s needs, your driving style, and your budget is paramount to a successful upgrade. The following sections will guide you through the crucial considerations.Vehicle-specific requirements play a significant role in selecting the appropriate brake upgrades.

Different vehicle types have varying braking needs. A high-performance sports car will require different components compared to a compact hatchback or a large SUV. Understanding the weight, speed capabilities, and overall design of your vehicle is crucial. Driving style also significantly impacts the choice of brake upgrade. Aggressive drivers demanding maximum braking performance will need different upgrades compared to drivers who prioritize everyday commuting.

Brake upgrades are a common modification for car owners, often desired for improved performance and safety. However, the rising popularity of the car subscription business model is changing how people approach car ownership. This means that even routine upgrades like brakes might become less of a personal project and more tied to the terms of a subscription agreement, impacting the decision-making process for prospective upgraders.

The budget, naturally, is a significant factor. The cost of brake upgrades can vary considerably depending on the type and quality of components. Ultimately, finding the right balance between performance, safety, and budget is key to a successful upgrade.

Vehicle Type and Driving Style Considerations

Vehicle type dictates the necessary braking capabilities. Heavy vehicles, such as SUVs or trucks, require more robust braking systems than smaller cars. Higher performance vehicles, designed for speed and handling, require upgraded components to maintain consistent stopping power. Driving style also significantly influences the brake upgrade selection. A driver who prioritizes safety and consistent braking will benefit from a different set of upgrades than an aggressive driver seeking maximum performance.

Consider your driving conditions and the frequency of heavy braking.

Comparing Upgrade Options

Various brake upgrade options exist, each with unique characteristics and benefits. Performance pads, designed for maximum braking power, often feature a higher coefficient of friction, but they can wear out faster than street pads. Street pads, on the other hand, are more suited for everyday driving, providing a balance between performance and longevity. Choosing the right option depends on the intended use and the driver’s needs.

Brake Upgrade Comparison Table

| Type of Upgrade | Features | Pros | Cons | Cost Range |

|---|---|---|---|---|

| Performance Pads | Higher coefficient of friction, optimized for high-performance braking. | Enhanced stopping power, especially at high speeds; better response to rapid braking. | Faster wear rate; potential for increased brake dust; may not be suitable for all driving conditions. | $80-$250+ per set |

| Street Pads | Balanced performance and longevity, designed for everyday driving. | Moderate stopping power; longer lifespan compared to performance pads; reduced brake dust. | Slightly lower stopping power compared to performance pads; less responsive to aggressive braking. | $50-$150+ per set |

| Performance Rotors | High-quality materials and construction, often with larger ventilation. | Improved heat dissipation, reducing fade; enhanced stopping power. | Increased cost compared to standard rotors; may require specific caliper upgrade. | $100-$300+ per set |

| Street Rotors | Standard material and design, suitable for everyday use. | Cost-effective; no need for additional upgrades. | May not provide the same performance as performance rotors; reduced heat dissipation. | $30-$100+ per set |

Installation Procedures

Installing brake upgrades correctly is crucial for safety and performance. Improper installation can lead to reduced braking efficiency, uneven wear, and potential accidents. This section provides a comprehensive guide to safely and effectively install your new brake components.Proper installation procedures, along with the correct tools and meticulous attention to detail, ensure optimal brake performance and safety. This includes precise measurements, careful alignment, and adherence to manufacturer specifications.

Safety Precautions

Before beginning any installation, prioritize safety. Wear appropriate safety gear, including eye protection, gloves, and closed-toe shoes. Work in a well-ventilated area, and ensure the vehicle is securely supported on jack stands or ramps. Disconnect the battery to prevent accidental electrical discharges. Never work under a vehicle without proper support.

Tools Required

The necessary tools vary depending on the specific brake upgrade. However, common tools include wrenches (various sizes), sockets, screwdrivers, pliers, a torque wrench, a measuring tape, a caliper, and a level. A digital caliper allows for precise measurements, which are vital for ensuring proper alignment. Refer to the manufacturer’s instructions for a complete list of recommended tools.

Measurement and Alignment

Accurate measurement and alignment of brake components are paramount. Use a measuring tape and caliper to precisely measure the distance between components and ensure that they are within the specified tolerances. Use a level to ensure that the brake calipers are mounted straight and parallel to the rotor. This guarantees even pad wear and optimal braking force.

Alignment is crucial for avoiding uneven braking and potential damage to the components. Pay particular attention to the specified clearance between brake components to avoid rubbing or binding.

Step-by-Step Installation Guide

| Step | Description/Image Description |

|---|---|

| 1 | Disconnect the battery and secure the vehicle on jack stands. Ensure the parking brake is engaged. |

| 2 | Remove the old brake pads and rotors. Carefully inspect for any damage or wear. Document the condition of all components for future reference. |

| 3 | Install the new brake pads, ensuring proper orientation. Use the appropriate shims or spacers. |

| 4 | Carefully mount the new brake rotors, adhering to the manufacturer’s specifications for torque and alignment. |

| 5 | Bleed the brake lines to remove any air trapped in the system. This process ensures smooth braking. |

| 6 | Reassemble all components. Thoroughly inspect the system for any leaks or misalignments. |

| 7 | Test the brakes and adjust if necessary. Ensure the brakes respond smoothly and evenly. |

| 8 | Lower the vehicle and reconnect the battery. Perform a thorough brake test drive on a clear, open road to ensure proper functionality. |

Performance Gains

Brake upgrades offer substantial improvements in vehicle performance, primarily by enhancing stopping power and reducing braking distances. This is crucial for safety and responsiveness, especially in dynamic driving situations. The right upgrades can significantly impact handling, making the vehicle more agile and controlled.A well-designed upgrade package, encompassing components like calipers, rotors, pads, and lines, collectively contributes to a more powerful and efficient braking system.

Modern upgrades leverage advanced materials and technologies to achieve optimal performance.

Improved Stopping Power

Brake upgrades significantly increase stopping power. This enhancement translates to quicker deceleration and reduced stopping distances, leading to a safer driving experience. Modern brake systems, when upgraded, often feature stronger calipers that exert greater pressure on the brake pads, resulting in more effective friction and deceleration. Consequently, a car equipped with upgraded brakes will achieve the same stopping power in less time.

Reduced Braking Distance

Upgraded braking components contribute to reduced braking distances. The increased stopping power, coupled with a refined braking system design, directly translates to a shorter distance required to bring the vehicle to a complete halt. This is especially beneficial in emergency situations. Consider a vehicle equipped with upgraded brakes. The reduced braking distance provides a tangible advantage, offering a safety margin when encountering sudden obstacles or needing to quickly decelerate.

Enhanced Handling Characteristics

Brake upgrades can enhance handling characteristics. This enhancement stems from the improved responsiveness of the braking system. Consistent and predictable braking allows for more precise control of the vehicle, enabling quicker and more controlled maneuvers. A car with upgraded brakes responds more quickly to driver input, contributing to improved agility. For instance, in cornering situations, the driver can rely on the enhanced stopping power to confidently adjust their trajectory, ensuring a safer and more controlled experience.

Comparative Braking Performance

| Condition | Stock Brakes | Upgraded Brakes |

|---|---|---|

| Normal Braking (100 km/h to 0 km/h) | Braking distance: 45 meters, Deceleration rate: 8.2 m/s2 | Braking distance: 40 meters, Deceleration rate: 9.1 m/s2 |

| Emergency Braking (120 km/h to 0 km/h) | Braking distance: 65 meters, Deceleration rate: 7.2 m/s2 | Braking distance: 55 meters, Deceleration rate: 8.5 m/s2 |

| High-Speed Braking (150 km/h to 0 km/h) | Braking distance: 95 meters, Deceleration rate: 6.1 m/s2 | Braking distance: 80 meters, Deceleration rate: 7.5 m/s2 |

Note: These are illustrative values and actual performance may vary based on vehicle specifics, road conditions, and driver input.

Maintenance and Care

Proper maintenance is crucial for maximizing the lifespan and performance of upgraded brake systems. Neglecting routine inspections and upkeep can lead to premature wear, reduced braking power, and potentially dangerous situations. Following a consistent maintenance schedule ensures optimal braking performance and safety.Maintaining upgraded brake systems requires a proactive approach. Understanding the specifics of your upgrade, and adhering to the manufacturer’s recommendations, is paramount.

This proactive approach will extend the life of the upgraded components and keep your braking system functioning at peak efficiency.

Importance of Post-Upgrade Brake Maintenance

Upgraded braking systems, often featuring higher-performance components, demand more careful attention. These components, such as upgraded brake pads and rotors, are engineered for superior stopping power but require specific maintenance practices to achieve their intended lifespan and performance. Proper maintenance prevents premature wear, ensures consistent braking, and ultimately improves safety.

Inspection and Maintenance Procedures

Regular visual inspections are essential for identifying potential issues early. Examine the brake pads for even wear, checking for any unusual noises or vibrations during braking. Visually inspect brake rotors for warping, scoring, or excessive rust. Thoroughly clean the brake calipers and components to ensure optimal cooling and functionality. A regular cleaning routine also allows for early detection of potential issues.

Frequency of Brake Pad and Rotor Replacement

The frequency of brake pad replacement and rotor inspection depends on driving habits, environmental conditions, and the specific upgrade. Aggressive driving styles, frequent stop-and-go traffic, and harsh road conditions will accelerate wear. Generally, brake pads should be replaced when they reach the minimum thickness specified by the manufacturer. Brake rotors should be inspected more frequently, potentially every 10,000 to 20,000 miles, or more often depending on the driving conditions.

Brake upgrades are crucial for any vehicle, especially when considering the demands of modern driving. This is especially relevant when considering the evolving landscape of smart mobility, which is changing how we interact with cars and the roads. Modern solutions in smart mobility, like adaptive cruise control systems, frequently rely on advanced braking technologies. Ultimately, quality brake upgrades are key to maintaining safety and efficiency, regardless of the evolving vehicle technology like those incorporated in smart mobility.

Tips for Prolonging Lifespan of Upgraded Components

Driving habits significantly influence the lifespan of brake components.

Gentle braking techniques, avoiding sudden stops and hard braking, can extend the life of both pads and rotors. Using quality brake fluids and maintaining proper brake fluid levels are also vital. Regular inspections and prompt replacements when necessary are key for maintaining the effectiveness of your upgraded braking system.Proper brake fluid changes are crucial. Follow manufacturer recommendations to maintain the fluid’s integrity.

Environmental factors, such as moisture and extreme temperatures, can negatively impact brake components. Using proper brake cleaner and avoiding harsh chemicals is critical for prolonging the life of your upgraded system.

Safety Considerations

Brake upgrades, while enhancing vehicle performance, necessitate meticulous attention to safety protocols. Improper installation or a lack of safety precautions can lead to severe consequences, from minor injuries to potentially catastrophic accidents. This section Artikels crucial safety measures to minimize risks during brake upgrades and maintenance.

Essential Safety Precautions

Adhering to safety precautions is paramount when undertaking brake upgrades. These precautions encompass both the physical environment and the specific procedures involved in the work. Safety gear and a structured approach to the project are critical for a safe outcome.

- Protective Gear: Always wear appropriate personal protective equipment (PPE). This includes safety glasses, gloves, a dust mask, and sturdy work boots. Eye protection safeguards against flying debris, while gloves protect hands from cuts and abrasions. A dust mask prevents inhalation of brake dust, and work boots provide ankle support, reducing the risk of slips and falls.

- Controlled Environment: Choose a well-ventilated and clear workspace. Avoid working in areas with obstructions or potential hazards. A well-lit area ensures visibility and reduces the risk of accidents. Clear the area around the vehicle to prevent obstacles during work.

- Proper Lifting Techniques: When handling heavy components, use proper lifting techniques to prevent strain injuries. Employ appropriate lifting equipment like hoists or dollies, if needed. Lifting heavy parts incorrectly can lead to back or other muscle injuries.

- Vehicle Stabilization: Ensure the vehicle is securely supported. Use jack stands or other appropriate support methods to prevent the vehicle from tipping over. The vehicle should be supported in a stable position to prevent accidents.

Potential Risks and Mitigation Strategies

Several potential risks can arise during brake upgrades. Understanding these risks and implementing effective mitigation strategies is crucial.

- Improper Installation: Faulty installation can compromise brake function, leading to reduced stopping power or unpredictable braking behavior. Following the manufacturer’s instructions meticulously and verifying the installation is correct can prevent such risks.

- Tool Damage: Using damaged or improper tools can lead to injuries or complications. Always ensure tools are in good working order before use. Inspecting tools for damage before use prevents equipment failure.

- Material Handling: Careless handling of brake components can result in damage or injury. Use appropriate handling procedures for each component to prevent damage.

Safety Guidelines Summary

This table summarizes key safety guidelines for brake upgrades.

| Safety Guideline | Description |

|---|---|

| Protective Gear | Wear safety glasses, gloves, dust mask, and sturdy work boots. |

| Workspace | Choose a well-ventilated and clear workspace. |

| Vehicle Support | Securely support the vehicle using jack stands or other appropriate methods. |

| Lifting Techniques | Use proper lifting techniques when handling heavy components. |

| Tool Inspection | Ensure tools are in good working order before use. |

Cost Analysis

Brake upgrades, while offering improved performance and safety, come with associated costs. Understanding these expenses is crucial for making informed decisions. This section details the financial aspects of various upgrade options, comparing them to the cost of repairing worn brakes.

Breakdown of Upgrade Costs

Different upgrade packages, from simple pad replacements to complete system overhauls, will have varying price points. The cost of parts, labor, and potential additional expenses like specialized tools or fluids should be factored in. For instance, upgrading to high-performance brake pads often requires matching calipers and rotors for optimal performance.

Parts Costs

The cost of brake upgrade parts can vary significantly depending on the make, model, and specific components being replaced. OEM (Original Equipment Manufacturer) parts, while generally reliable, can be more expensive than aftermarket options. However, aftermarket parts can also vary greatly in quality and durability. Consider researching and comparing prices from various suppliers to get the best value.

Labor Costs

Labor costs associated with brake upgrades vary based on the complexity of the job and the mechanic’s rates. Simple pad replacements usually have lower labor costs than more extensive upgrades, such as replacing calipers or rotors. Shop around for quotes from different mechanics to compare prices.

Additional Expenses

Beyond parts and labor, there might be additional expenses, such as specialized tools or fluids required for the upgrade. For example, some brake fluid types are designed for high-performance applications and can increase the overall cost. Research the specific requirements of your chosen upgrade package to anticipate any additional expenses.

Upgrade Package Cost Breakdown

- Basic Pad Replacement: This package typically involves replacing brake pads and possibly rotors. The cost for this option usually ranges from $200 to $500, depending on the vehicle and specific components needed.

- Calipers and Rotors Upgrade: This upgrade includes replacing brake calipers and rotors. This option is more costly than a basic pad replacement, typically ranging from $500 to $1500.

- Complete System Upgrade: This option involves replacing all brake components, including calipers, rotors, pads, and potentially brake lines. It’s the most expensive option, generally exceeding $1500.

Comparison with Repair Costs

Comparing the cost of upgrading brakes to the cost of repairing worn brakes is essential. While upgrades offer enhanced performance and safety, the upfront cost might be higher than simply repairing worn components. However, the long-term savings from improved braking performance and reduced repair frequency should be considered. A worn brake system might require multiple repairs over time, potentially leading to higher cumulative costs than a well-executed upgrade.

Cost Comparison Table

| Upgrade Component | Estimated Cost (USD) |

|---|---|

| Brake Pads (Front) | $50-$150 |

| Brake Pads (Rear) | $40-$120 |

| Brake Rotors (Front) | $80-$250 |

| Brake Rotors (Rear) | $60-$200 |

| Brake Calipers (Front) | $200-$600 |

| Brake Calipers (Rear) | $150-$450 |

| Brake Fluid | $10-$30 |

| Labor (Basic Pad Replacement) | $100-$250 |

| Labor (Calipers and Rotors Upgrade) | $200-$500 |

Troubleshooting Common Issues

After upgrading your brakes, it’s important to be aware of potential issues and how to address them. Proper troubleshooting can prevent further problems and ensure optimal brake performance. Understanding the potential causes and solutions can save you time and money.Troubleshooting brake issues involves careful observation and systematic analysis. By understanding the common problems, their causes, and effective solutions, you can maintain the integrity and performance of your upgraded brake system.

Identifying Common Brake Problems

A thorough understanding of potential brake problems is crucial for effective troubleshooting. This involves recognizing symptoms and understanding the potential causes behind them. Proper identification allows for targeted solutions and prevents further complications.

- Reduced braking power: This can be caused by low brake fluid levels, worn brake pads, or a malfunctioning brake booster. Regular brake fluid checks and pad replacements are essential to maintain optimal braking power.

- Squealing or grinding noises: Unusual noises during braking often indicate worn brake components. Worn brake pads, rotors, or calipers may need immediate attention.

- Pulling or uneven braking: This can arise from issues with the brake caliper alignment, uneven pad wear, or warped rotors. Proper brake caliper alignment and rotor replacement can often resolve this problem.

- Brake pedal pulsation: Pulsating or vibrating brake pedals may signal issues with warped rotors, uneven pad wear, or loose caliper components. Checking rotor condition and pad wear is necessary.

- Brake fluid leaks: Leaks in the brake lines or components can lead to reduced braking power and necessitate immediate repair.

Troubleshooting Steps

Effective troubleshooting involves a systematic approach to identify and resolve problems. The steps Artikeld below can help you address potential issues.

- Visual Inspection: Carefully inspect the brake system for any visible signs of damage, such as leaks, frayed lines, or damaged components. Check the brake fluid reservoir level. Low levels indicate a leak or loss of fluid, and should be addressed immediately.

- Brake Pedal Feel: Assess the feel of the brake pedal. A spongy or soft pedal could signal a low brake fluid level, while a hard pedal may indicate a problem with the brake booster or lines. A firm, consistent pedal feel is desirable.

- Listening for Noises: Pay close attention to any unusual noises, such as squealing or grinding, during braking. These noises often indicate worn brake components.

- Professional Diagnosis: If you’re unable to identify the problem or determine the solution, seek professional help. A qualified mechanic can perform a thorough diagnosis and implement the necessary repairs.

Importance of Seeking Professional Help, Brake upgrades

Professional assistance is essential for complex or ambiguous brake issues. Specialized tools and expertise are required for accurate diagnosis and repair.

Professional mechanics have the necessary training, tools, and experience to diagnose and repair brake problems accurately. This ensures the safety and reliability of the brake system.

Table of Common Brake Problems

| Problem | Potential Causes | Solutions |

|---|---|---|

| Reduced braking power | Low brake fluid, worn brake pads, faulty brake booster | Check and top up brake fluid, replace worn pads, repair/replace brake booster |

| Squealing/Grinding noises | Worn brake pads, rotors, or calipers | Replace worn brake pads, rotors, or calipers |

| Pulling/Uneven braking | Misaligned calipers, uneven pad wear, warped rotors | Adjust caliper alignment, replace pads, replace rotors |

| Brake pedal pulsation | Warped rotors, uneven pad wear, loose caliper components | Replace rotors, replace pads, tighten caliper components |

| Brake fluid leaks | Damaged brake lines or components | Repair or replace damaged brake lines or components |

Environmental Impact

Brake upgrades, while enhancing performance and safety, can have an impact on the environment. Careful consideration of materials, manufacturing processes, and disposal methods is crucial for minimizing this impact. Sustainable practices and the selection of environmentally friendly components play a vital role in mitigating the negative effects of brake upgrades.The choice of materials used in brake components significantly influences their environmental footprint.

Modern brake upgrades often utilize advanced alloys and composite materials, which can offer superior performance but may also have varying environmental impacts depending on their composition and sourcing. Understanding the life cycle of these materials, from extraction to disposal, is essential for informed decision-making.

Material Considerations

Brake components are often crafted from metals like steel, aluminum, and copper alloys, or composites like carbon fiber and ceramics. The environmental impact varies based on the specific materials used. For instance, the extraction and processing of rare earth elements used in some advanced alloys can have significant environmental consequences. Similarly, the manufacturing process itself, involving energy consumption and waste generation, needs careful evaluation.

Disposal Procedures

Proper disposal of worn-out brake components is crucial. Many brake materials are recyclable, but the process often requires specialized facilities and careful sorting. Ensuring that worn-out components are collected and recycled appropriately minimizes environmental harm and conserves resources. Furthermore, the disposal of brake fluids, if not handled properly, can lead to environmental contamination. Proper disposal procedures are essential to prevent pollution.

Sustainable Practices

Adopting sustainable practices in brake upgrade selection involves several key considerations. Prioritizing components made from recycled materials, or those with minimal environmental impact throughout their lifecycle, can contribute to reducing the overall environmental footprint. Choosing brake upgrades from manufacturers committed to sustainability and responsible sourcing can also play a vital role.

Environmentally Friendly Components

Several brake components are being developed with sustainability in mind. For example, some manufacturers are exploring the use of bio-based materials in certain components, which can reduce reliance on fossil fuels and minimize the use of non-renewable resources. Recycled materials are also being incorporated into brake pads and rotors, reducing the demand for raw materials. Additionally, some manufacturers are focusing on reducing the energy consumption required during the manufacturing process.

Environmental Considerations Table

| Brake Upgrade Option | Material Composition | Manufacturing Impact | Disposal Concerns | Sustainability Rating |

|---|---|---|---|---|

| Traditional Steel Brake Pads | Steel, asbestos (often banned) | High energy consumption | Potential for metal contamination | Low |

| Ceramic Brake Pads | Ceramic, metal | Medium energy consumption | Potentially complex recycling | Medium |

| Carbon Fiber Brake Rotors | Carbon fiber, metal | High energy consumption in some cases | Potentially complex recycling | Medium-High |

| Bio-based Brake Pads | Bio-based polymers, metals | Lower energy consumption (potential) | Potentially easier recycling | High |

Alternative Upgrade Methods: Brake Upgrades

Improving braking performance doesn’t always necessitate a full brake upgrade. Various alternative methods can enhance stopping power and safety without the substantial cost and effort of replacing components. These methods often target specific aspects of the braking system, such as pad material or fluid properties. Understanding the trade-offs associated with these alternatives is crucial for making informed decisions.

Brake Fluid Improvements

Brake fluid plays a critical role in hydraulic braking systems. Higher-quality brake fluids, often formulated with improved resistance to temperature fluctuations, can lead to more consistent braking performance. These fluids maintain pressure more effectively, resulting in a firmer pedal feel and improved stopping power. While not a complete overhaul, this approach can offer significant improvements in pedal response and feel.

Brake Pad Compound Changes

Brake pads are another crucial component in the braking system. Selecting pads with different compounds can affect braking performance. For instance, some compounds offer better stopping power on dry roads, while others are optimized for wet conditions. This approach requires careful consideration of driving conditions and desired performance characteristics. A more aggressive compound might improve stopping power, but at the cost of potential noise and wear.

Rotor Surface Treatments

Rotor surface treatments can modify the friction characteristics of brake rotors. Various coatings and treatments aim to reduce friction, increase heat dissipation, and enhance stopping power. These treatments can significantly reduce the risk of brake fade, a common issue in high-performance braking systems. The longevity and effectiveness of these treatments depend heavily on the quality of the treatment and the driving conditions.

Comparison of Alternative Upgrade Methods

| Upgrade Method | Pros | Cons |

|---|---|---|

| Brake Fluid Improvements | Improved pedal feel, consistent performance, potentially reduced fade, relatively inexpensive | Limited performance gains compared to full upgrades, effectiveness varies with fluid quality, may not address underlying system issues |

| Brake Pad Compound Changes | Improved stopping power in specific conditions (dry/wet), enhanced braking feel, potentially better longevity with specific compounds | May require adjustments to braking system, can affect noise levels, potential for increased wear on rotors |

| Rotor Surface Treatments | Reduced brake fade, improved heat dissipation, enhanced stopping power, potentially extended rotor life | Cost can vary depending on the treatment, effectiveness may be limited depending on rotor material, may not be suitable for all types of driving conditions |

Conclusive Thoughts

In conclusion, upgrading your brakes is a significant investment in vehicle safety and performance. By carefully considering the various options, installation procedures, and long-term maintenance, you can significantly improve your driving experience. This guide has provided a comprehensive overview of brake upgrades, equipping you with the knowledge to make informed decisions. Remember to prioritize safety throughout the entire process, and don’t hesitate to consult professionals if needed.

Helpful Answers

What are the most common brake upgrade mistakes?

Improper installation, using incompatible parts, and neglecting proper maintenance are common mistakes. Ensuring proper installation and using OEM-approved parts are crucial for avoiding issues.

How long do upgraded brake pads typically last?

The lifespan of upgraded brake pads depends on driving habits, environmental conditions, and the specific pad material. However, generally, upgraded pads can last longer than stock pads, but proper maintenance is still crucial.

Are there any alternative methods to improve braking besides full upgrades?

Yes, alternative methods like brake fluid changes and proper tire inflation can improve braking performance. However, these methods may not offer the same level of performance enhancement as a full brake upgrade.

What are the environmental considerations for different brake upgrade options?

Environmental impact varies based on the materials used in the upgrades. Consider the sustainability of materials and disposal methods during your selection process.