Brake calipers are the crucial components that bring your vehicle to a halt. Understanding their function, types, maintenance, and potential issues is essential for any driver. This guide delves into the intricacies of brake calipers, from their fundamental role in braking systems to the advanced engineering behind their design.

Different types of calipers exist, each tailored to specific vehicle needs and performance requirements. Single-piston calipers provide basic stopping power, while dual-piston and four-piston options offer enhanced stopping power for various driving conditions. This article will explore these differences in detail, providing a comprehensive comparison table for easy understanding.

Introduction to Brake Calipers

Brake calipers are crucial components in a vehicle’s braking system. They are responsible for applying pressure to brake pads, which in turn create friction against the brake rotors to slow or stop the vehicle. Understanding their function and various types is essential for appreciating the complexity and performance of modern braking systems.Brake calipers are essentially hydraulic pistons housed within a structure.

When the driver depresses the brake pedal, hydraulic pressure is transmitted through brake lines to the calipers. This pressure forces the pistons within the calipers outward, pushing the brake pads against the brake rotors, generating the friction needed to slow or stop the vehicle. The efficiency and effectiveness of this process are directly tied to the design and materials of the calipers.

Types of Brake Calipers

Different types of brake calipers are designed to meet varying performance needs and cost considerations. Understanding the distinctions between these types is important for choosing the right caliper for a specific application.

- Single-piston calipers are the simplest type, featuring a single piston to apply pressure to the brake pads. Their straightforward design typically leads to lower manufacturing costs. However, this simplicity often translates to lower stopping power compared to more complex designs.

- Dual-piston calipers employ two pistons to apply pressure, increasing the clamping force on the brake pads. This results in a noticeable improvement in stopping power compared to single-piston calipers. They strike a balance between cost and performance.

- Four-piston calipers utilize four pistons to generate even higher clamping force, delivering the most significant stopping power. These are frequently found in high-performance vehicles, sports cars, and trucks needing superior braking capability. The increased complexity of the design translates into higher manufacturing costs.

Materials Used in Brake Caliper Construction

The materials used in brake caliper construction are critical for ensuring durability, heat dissipation, and resistance to corrosion. Different materials offer varying degrees of performance and cost-effectiveness.

- Cast iron is a common material due to its excellent heat dissipation properties. However, its weight can contribute to a higher unsprung mass, impacting ride comfort. Its cost-effectiveness makes it suitable for applications requiring reasonable stopping power without extreme performance needs.

- Aluminum alloys are increasingly used due to their lightweight nature. This contributes to a better balance of performance and handling characteristics, especially for vehicles requiring high performance or fuel efficiency. While lightweight, aluminum’s heat dissipation capabilities might be slightly lower than cast iron, which requires careful design considerations.

- Forged steel is another option, providing high strength and stiffness. This is particularly important in high-performance applications where reliability and resistance to deformation under high stress are crucial. However, forged steel typically comes at a higher cost compared to other materials.

Performance Comparison of Caliper Types

The table below summarizes the performance characteristics of different caliper types. This comparison highlights the trade-offs between stopping power, cost, and complexity.

| Caliper Type | Piston Count | Stopping Power | Cost |

|---|---|---|---|

| Single-piston | 1 | Low | Low |

| Dual-piston | 2 | Medium | Medium |

| Four-piston | 4 | High | High |

Components of Brake Calipers

Brake calipers, the heart of your vehicle’s braking system, are intricate assemblies. Understanding their components and how they work is crucial for maintaining efficient and safe braking. Their design allows for precise control of the braking force, translating pedal pressure into the necessary friction to slow or stop the vehicle.

Caliper Pistons

Caliper pistons are the primary force-transmitting components within a brake caliper. They convert the hydraulic pressure from the brake fluid into mechanical force, pushing the brake pads against the brake rotors. The precise design of the piston, typically a cylindrical shape, is vital for uniform pressure distribution and efficient braking. Different piston designs cater to various braking needs, optimizing performance based on vehicle type and driving conditions.

Caliper Seals

Caliper seals are critical components that maintain the integrity of the brake fluid within the caliper system. These seals prevent brake fluid leakage, ensuring consistent hydraulic pressure throughout the braking process. They are often made of resilient materials like silicone or rubber, with various thicknesses catering to different piston sizes and operating conditions. Their consistent performance is crucial for maintaining the efficiency of the braking system.

Brake Hoses

Brake hoses are essential for transferring the hydraulic pressure from the master cylinder to the brake calipers. They are typically made of flexible rubber or reinforced metal, ensuring flexibility and durability during use. Hoses are designed with various lengths, depending on the vehicle’s design and the location of the calipers. Properly maintained brake hoses are vital for preventing brake failure due to leakage or damage.

Typical Dimensions of Brake Caliper Components

| Component | Dimension | Material |

|---|---|---|

| Caliper Piston | Diameter (e.g., 25mm, 30mm, 40mm) | Steel/Aluminum |

| Caliper Seal | Thickness (e.g., 2mm, 3mm) | Silicone/Rubber |

| Brake Hose | Length (e.g., 150mm, 200mm, 300mm) | Rubber/Metal |

Note: Dimensions vary significantly based on vehicle type and specific brake system design. These are just examples.

Caliper Assembly Process

The assembly of a brake caliper involves carefully aligning and securing its components. First, the pistons are installed within the caliper body. Next, the seals are placed around the pistons, ensuring a tight and leak-proof fit. The brake pads are then positioned on the caliper’s backing plates. Finally, the brake hose is connected to the caliper and secured to prevent leaks.

Each step is crucial to prevent issues with the brake system’s operation and performance.

Brake Caliper Maintenance and Repair: Brake Calipers

Proper brake caliper maintenance is crucial for ensuring safe and reliable vehicle operation. Neglecting these components can lead to brake failure, posing significant risks on the road. Regular inspections and timely repairs are essential to prevent costly replacements and maintain optimal braking performance.

Common Maintenance Procedures

Regular maintenance procedures for brake calipers include visual inspections, lubrication, and cleaning. These routine checks help identify potential issues early on, preventing more serious problems and extending the lifespan of the brake system. Visual inspections should focus on the caliper’s overall condition, looking for signs of corrosion, damage, or leaks. Lubrication of moving parts, such as the piston and slide pins, is important to maintain smooth operation and prevent friction.

Cleaning the caliper and surrounding components removes dirt, debris, and rust, preventing them from interfering with the braking mechanism.

Identifying Signs of Wear and Tear

Recognizing the signs of brake caliper wear and tear is vital for proactive maintenance. A spongy or unresponsive brake pedal is a common indicator of potential issues. Unusual noises, such as grinding or squealing sounds, during braking, also suggest problems. Visual inspection can reveal corrosion, pitting, or cracks on the caliper body, or signs of fluid leaks.

Additionally, reduced braking force or uneven braking feel may indicate internal wear within the caliper. By understanding these indicators, drivers can address the issue promptly and avoid potential hazards.

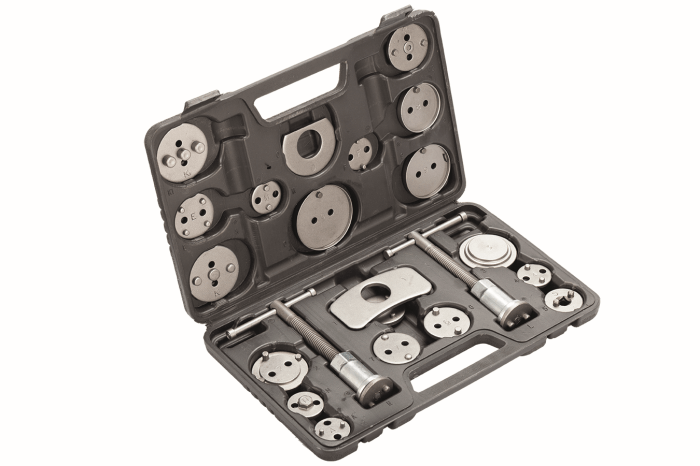

Replacing a Brake Caliper

Replacing a brake caliper is a more involved procedure, requiring specific tools and knowledge. Before commencing the replacement process, ensure all necessary tools and parts are readily available. Disconnect the brake line from the caliper, and carefully remove the caliper from the vehicle’s braking system. Inspect the piston and ensure it moves freely. Install the new caliper, ensuring proper alignment and connection of the brake line.

Finally, bleed the brake system to eliminate any air trapped within the lines. Following these steps with precision is critical to maintaining a safe braking system.

Proper Caliper Bleeding Procedures

Proper caliper bleeding procedures are essential to eliminate air bubbles in the brake system. Improper bleeding can result in inconsistent braking performance, reduced braking power, and potential brake failure. Using a brake bleeder tool, slowly release the brake fluid to remove air pockets. Carefully monitor the fluid level during the process and refill as needed. Thorough bleeding ensures a smooth and effective braking system.

Brake Caliper Design and Engineering

Brake caliper design is a critical aspect of vehicle braking systems, directly influencing performance, safety, and longevity. Sophisticated engineering principles are applied to ensure efficient braking power while maintaining durability and cost-effectiveness. Different designs cater to varying vehicle types and performance requirements.Brake caliper design considerations are multifaceted. Engineers must balance performance needs with manufacturing constraints and cost-effectiveness.

Brake calipers are crucial for vehicle safety, ensuring smooth stopping. A helpful aid for maneuvering, like a 360-degree parking camera , can be a real asset when parking. Ultimately, the combination of these safety features, both in the braking system and visual aids, contributes to a more secure driving experience.

These considerations include the need for adequate braking force, efficient heat dissipation, and a robust design that can withstand the stresses of repeated use.

Brake calipers are crucial components in any vehicle, but their effectiveness is also intertwined with urban transport policies. Properly designed and maintained calipers are essential for safe urban driving, impacting everything from traffic flow to the overall safety of the public transport system. Factors like vehicle weight limits and road infrastructure, as outlined in urban transport policies , influence the types of calipers needed for safe operation in a given environment.

Ultimately, robust brake calipers are paramount for a well-functioning urban transport system.

Design Considerations in Brake Caliper Engineering

Various factors are carefully evaluated during the design process. These factors include the desired stopping power, the vehicle’s weight and size, and the operating temperature range. Material selection, hydraulic system design, and overall mechanical structure are critical considerations. Optimal design balances performance with cost and manufacturability.

Different Brake Caliper Designs and Their Advantages/Disadvantages

Several designs exist for brake calipers, each with unique advantages and disadvantages.

- Floating Calipers: These calipers feature a floating piston design that allows the caliper to move slightly during braking. This design typically provides better heat dissipation and reduces brake pad wear. However, it can be slightly less precise in terms of brake pad engagement compared to fixed calipers.

- Fixed Calipers: These calipers have a fixed mounting position. This design often leads to more precise brake pad engagement, contributing to more consistent braking performance. Heat dissipation might be slightly less efficient than in floating calipers, which can be an issue in high-performance braking applications.

- Single-piston Calipers: These calipers are simpler and less expensive to manufacture. They are generally suitable for lighter vehicles and offer adequate braking performance in everyday driving conditions. However, they may not offer the same stopping power as multi-piston designs for higher-performance applications.

- Multi-piston Calipers: These calipers employ multiple pistons for increased clamping force, resulting in superior stopping power and responsiveness. They are commonly found in high-performance vehicles and offer significantly enhanced braking capability. The added complexity and cost are significant drawbacks.

Impact of Materials Selection on Caliper Performance

The choice of materials significantly impacts caliper performance. Materials must be able to withstand high temperatures, pressures, and wear.

- Cast Iron: Cast iron calipers are cost-effective but can have limited heat dissipation, leading to potential overheating issues. This is often mitigated by incorporating fins or other cooling enhancements.

- Aluminum Alloys: Aluminum alloys are lighter than cast iron, contributing to improved vehicle performance. They also exhibit better heat dissipation characteristics, making them suitable for high-performance applications.

- Steel: Steel calipers offer a balance between strength, durability, and weight. They are frequently used in applications requiring a robust structure, though they may not provide the same heat dissipation as aluminum.

Safety Standards for Brake Calipers

Adherence to established safety standards is paramount. These standards ensure consistent quality and performance across various brake caliper designs.

| Standard | Description | Compliance |

|---|---|---|

| SAE J2525 | Brake system safety | Must meet |

| ISO 16890 | Brake performance standards | Must meet |

SAE J2525 and ISO 16890 standards are critical benchmarks for ensuring brake system safety and performance, ensuring consistency and safety across the industry.

Troubleshooting Brake Caliper Issues

Brake calipers, crucial components in a vehicle’s braking system, are susceptible to various malfunctions. Proper diagnosis and repair are essential to ensure safe and reliable operation. This section details common problems, their causes, and effective troubleshooting methods.

Common Brake Caliper Problems

Identifying the specific issue is the first step in successful repair. Common problems include squeaking, dragging, and fluid leaks. Understanding the symptoms and their potential causes aids in efficient diagnosis and targeted repairs.

Squeaking Brake Calipers

Squeaking noises during braking often indicate friction between components. This friction can arise from various factors, including worn or damaged brake pads, warped rotors, or improper pad installation. Inspecting the brake pads for excessive wear and the rotors for irregularities is critical. Proper lubrication of the caliper’s sliding pins and bushings can also resolve this issue.

Dragging Brake Calipers

A dragging caliper manifests as a consistent pulling sensation or a feeling of resistance during braking. This often results from a sticking piston, a seized caliper, or improperly adjusted caliper components. Visually inspecting the caliper for any obvious obstructions and checking the piston for proper movement are initial steps. A caliper may require disassembly and lubrication of internal components to restore smooth operation.

Fluid Leaks from Brake Calipers

Fluid leaks from the caliper can stem from various causes, including damaged seals, worn hoses, or cracks in the caliper itself. A leak can lead to a loss of brake fluid, potentially compromising braking performance and safety. Inspecting the caliper for any cracks, damage to seals, or leaks from the mounting bolts is crucial. Replacing worn seals or damaged components is necessary to address the leak.

Diagnosis Methods for Caliper Issues

Diagnosing brake caliper problems requires a systematic approach. Visual inspection for leaks, damage, or obstructions is a primary step. Using a brake pressure gauge can help determine if the caliper is functioning correctly under pressure. Listening for noises during braking provides clues to the location and nature of the issue.

Repairing Caliper Issues

Repairing brake caliper issues necessitates a methodical approach. For squeaking, addressing worn components, adjusting pad installation, and lubricating sliding pins are common solutions. Dragging calipers may require cleaning, lubricating, or replacing the piston or internal components. Fluid leaks require replacing damaged seals, hoses, or the caliper itself. In all cases, following manufacturer guidelines and safety precautions is essential.

Importance of Proper Maintenance

Regular maintenance, including inspecting brake pads for wear and visually checking the calipers for leaks or damage, is vital to prevent potential issues. Early detection and intervention can significantly reduce the likelihood of costly repairs and ensure the safety of the vehicle’s braking system.

Brake Caliper Performance and Efficiency

Brake caliper performance is crucial for vehicle safety and optimal stopping power. Understanding the factors influencing this performance allows for informed decisions regarding maintenance, repair, and even vehicle upgrades. Efficient brake calipers minimize stopping distances, contributing to overall vehicle safety.Factors influencing brake caliper performance are multifaceted and interrelated. Material properties of the caliper components, including the piston, bracket, and mounting hardware, significantly impact performance.

The design of the caliper, the friction materials used in the pads, and the overall system hydraulics all play a vital role in determining efficiency.

Factors Affecting Stopping Distances

Stopping distance is a critical parameter directly influenced by several factors inherent to the brake caliper system. A combination of these elements, interacting dynamically, determines the final stopping distance.

- Vehicle Speed: Higher speeds necessitate longer stopping distances, as the kinetic energy of the vehicle needs to be dissipated. A higher initial speed translates directly to a longer distance needed to decelerate to a complete stop. For instance, stopping a vehicle traveling at 60 mph will require a considerably longer distance compared to stopping the same vehicle at 30 mph.

- Road Conditions: The coefficient of friction between the tires and the road surface plays a critical role. Wet or icy roads drastically reduce the friction, leading to significantly longer stopping distances. Conversely, dry pavement offers higher friction, resulting in shorter stopping distances. This highlights the importance of road conditions in evaluating stopping distances.

- Brake Pad Material and Condition: The friction characteristics of brake pads are directly correlated to stopping distance. New, properly-maintained brake pads offer optimal friction. Worn or contaminated pads can significantly reduce friction, increasing stopping distances. A comparison of various pad materials can highlight the differences in friction coefficients and stopping distances.

- Hydraulic System Pressure: A consistent and sufficient hydraulic pressure is essential for effective brake caliper operation. Low hydraulic pressure can reduce the clamping force on the brake rotors, leading to longer stopping distances. Conversely, excessive pressure, while not typically an issue, may potentially affect the caliper’s operation and may not result in improved stopping distances.

Caliper Type Comparisons

Different caliper types exhibit varying degrees of efficiency. The choice of caliper type often depends on the specific vehicle’s needs and design constraints.

| Caliper Type | Efficiency | Advantages | Disadvantages |

|---|---|---|---|

| Single-piston calipers | Lower | Cost-effective | Less stopping power, potentially prone to fading |

| Dual-piston calipers | Moderate | Improved stopping power over single-piston | Higher cost compared to single-piston |

| Four-piston calipers | High | Excellent stopping power, suitable for high-performance vehicles | Higher cost, potential for increased unsprung weight |

| Floating calipers | Moderate to High | Reduced stress on the mounting points, potentially improving braking efficiency | More complex design, slightly increased maintenance |

The table above highlights a general comparison. Actual performance can vary depending on the specific design, materials, and manufacturing tolerances of each caliper type.

Brake Caliper Applications

Brake calipers, the crucial components responsible for stopping a vehicle, exhibit diverse design considerations based on the specific application. Understanding these variations is vital for ensuring optimal braking performance across a range of vehicle types and conditions. From the compact efficiency of a small car to the substantial demands of a heavy-duty truck, the design principles of brake calipers adapt to meet the specific needs of each application.Different vehicle types necessitate varying caliper designs to accommodate diverse weight, speed, and braking requirements.

This necessitates understanding the specific design constraints and performance targets for each application. The following sections detail these considerations.

Types of Vehicles Using Brake Calipers

Brake calipers are integral components in a wide spectrum of vehicles. Their design and function are adapted to the specific needs of each vehicle type.

- Passenger Cars: These vehicles typically feature smaller calipers designed for moderate braking forces. The calipers are often integrated with compact hydraulic systems to maintain responsiveness and efficiency.

- Light Trucks and SUVs: These vehicles often require larger calipers to handle the increased weight and potential for higher speeds. The design incorporates stronger materials and potentially more complex hydraulic systems to maintain stopping power.

- Heavy-Duty Trucks: The demanding braking requirements of heavy-duty trucks necessitate robust calipers capable of withstanding significant forces. These calipers frequently feature larger pistons, stronger materials, and more robust hydraulic systems to accommodate the substantial weight and braking demands.

- Motorcycles: Motorcycle calipers often employ smaller designs with lighter materials, but with a focus on responsiveness and high-efficiency braking. The design is often optimized for quick and precise stopping capabilities.

- Race Cars: The design of calipers for race cars emphasizes maximum braking performance. This frequently involves lightweight materials, high-performance hydraulics, and innovative designs to minimize weight and maximize braking forces.

Design Requirements for Different Vehicle Applications

Various factors influence the design requirements for different vehicle types. These considerations are crucial in ensuring optimal performance and safety.

- Weight Capacity: The weight of the vehicle significantly impacts the design requirements. Heavier vehicles necessitate larger calipers with increased piston sizes and stronger materials to generate the required braking force.

- Speed and Performance: High-performance vehicles and race cars demand calipers that provide rapid and responsive braking at high speeds. This typically involves lightweight materials, optimized hydraulic systems, and precision-engineered components.

- Operating Conditions: The operating conditions, such as temperature extremes and potential for corrosion, influence the material selection and design of the calipers. Robust materials that can withstand these conditions are essential.

- Cost-Effectiveness: The cost of the calipers is a crucial factor in the design process. Balancing performance with cost-effectiveness is vital for mass-produced vehicles.

Impact of Vehicle Weight on Caliper Design

Vehicle weight is a critical factor in determining the appropriate caliper design. Higher vehicle weights demand larger calipers to generate the necessary braking force.

- Increased Braking Force: A heavier vehicle requires a greater braking force to achieve the same stopping distance as a lighter vehicle. Larger calipers with increased piston areas are needed to generate this additional force.

- Material Strength: To withstand the higher forces, calipers for heavier vehicles must be constructed from stronger and more durable materials. This often includes using alloys with higher tensile strength.

- Hydraulic System: The hydraulic system must also be robust enough to handle the increased pressure demands of a heavier vehicle. This might involve larger hydraulic lines and components.

- Example: A heavy-duty truck, with its substantial weight, necessitates significantly larger calipers compared to a compact car. The calipers in a truck need to be more robust to withstand the higher braking forces.

History of Brake Caliper Evolution

The evolution of brake calipers reflects a continuous quest for improved stopping power, durability, and efficiency. Early designs, often rudimentary and prone to failure, paved the way for the sophisticated systems we see today. This journey involves not only advancements in design but also a significant shift in materials and technologies, leading to a substantial increase in safety and performance.

Early Brake Caliper Designs

Early automobiles relied on rudimentary braking systems, often employing drum brakes. Brake calipers, in their nascent form, were less sophisticated than their modern counterparts. These early designs were frequently made of cast iron and lacked the precision machining that is now commonplace. They faced limitations in terms of stopping power and durability, particularly in high-speed applications.

Advancements in Materials

The transition from cast iron to more advanced materials significantly improved the performance and longevity of brake calipers. Aluminum alloys, for instance, brought about lighter designs without sacrificing strength, leading to better fuel efficiency. Further refinements involved the introduction of high-strength steel alloys, enhancing resistance to wear and tear. Composite materials have also shown promise, offering a balance between weight and performance.

Technological Innovations

Technological innovations have profoundly shaped brake caliper design. The development of precision machining techniques enabled more intricate geometries, improving friction and heat dissipation. Hydraulic systems, crucial for transmitting force effectively, have evolved to include sophisticated pressure control mechanisms, resulting in improved braking responsiveness. Modern designs also incorporate sensors and actuators for advanced driver-assistance systems, like anti-lock braking systems (ABS).

Challenges in Development

The development of brake calipers has faced numerous challenges. Balancing strength and weight has been a critical consideration, particularly in high-performance vehicles. Heat dissipation, a major concern in high-speed braking, has necessitated innovative designs and materials to prevent overheating and potential failure. Ensuring consistent performance across a wide range of operating conditions, from extreme temperatures to varied driving styles, has also posed a substantial challenge.

Examples of Key Advancements

One key advancement involved the introduction of floating calipers. These designs, compared to fixed calipers, offer improved heat dissipation, enabling more powerful braking systems. This design improvement allowed for enhanced braking performance in high-speed scenarios, which was critical in the evolution of high-performance vehicles. Another example includes the use of ceramic brake pads, which offer increased friction and durability, leading to a more responsive and lasting braking system.

Materials and Technologies in Modern Calipers

Modern brake calipers frequently incorporate advanced materials like high-strength aluminum alloys and specialized steels. Precision machining techniques are employed to create intricate geometries, optimizing heat dissipation and friction. These improvements contribute to improved braking efficiency and durability, allowing for more reliable and consistent performance.

Future Trends in Brake Caliper Technology

Brake caliper technology is constantly evolving, driven by the need for enhanced safety, improved performance, and reduced environmental impact. Future trends in brake caliper design will focus on innovative materials, advanced manufacturing techniques, and sophisticated control systems. This will lead to lighter, more efficient, and potentially more cost-effective braking systems.Future brake calipers will likely incorporate significant advancements in materials science, design principles, and manufacturing processes.

This will be reflected in improved performance characteristics, potentially exceeding current standards in terms of stopping power and efficiency.

Material Advancements

Brake calipers are subjected to high temperatures and pressures during operation. Consequently, materials with superior heat resistance, strength, and corrosion resistance are crucial. Composite materials, such as carbon fiber-reinforced polymers, are being explored for their lightweight nature and high strength-to-weight ratio. This could lead to lighter brake calipers, potentially reducing unsprung mass and improving overall vehicle handling.

Furthermore, advanced alloys with improved heat dissipation and fatigue resistance are being researched, enabling calipers to withstand more demanding conditions without compromising performance.

Design Innovations

Innovative designs are being developed to optimize hydraulic flow and improve heat dissipation. One area of focus is the integration of more efficient cooling channels within the caliper design, enhancing heat transfer to surrounding components. Additionally, advanced fluid management systems are being considered, potentially reducing fluid loss and improving the consistency of braking performance across different operating conditions.

Manufacturing Processes

The development of advanced manufacturing techniques, such as 3D printing and additive manufacturing, is expected to significantly impact brake caliper production. These methods offer greater design flexibility and the potential for creating complex geometries, leading to more intricate and efficient cooling systems within the caliper. Moreover, they can enable the creation of lightweight, optimized parts, reducing overall system mass.

The use of these methods is already evident in prototype development, with potential for wider implementation in the near future.

Performance and Efficiency Improvements

The future holds promise for significant improvements in brake caliper performance and efficiency. Integration of advanced sensors and actuators, coupled with sophisticated control algorithms, could lead to adaptive braking systems. These systems could adjust braking force in real-time based on various factors, such as road conditions, vehicle speed, and driver input. The result would be a significant increase in braking responsiveness and consistency, potentially enhancing safety and reducing stopping distances.

Predictive maintenance capabilities are also being developed, allowing for proactive identification of potential issues and preventing catastrophic failures. This approach would not only enhance safety but also reduce downtime and maintenance costs.

Brake Caliper Safety Considerations

Proper brake caliper installation and maintenance are paramount for vehicle safety. Faulty calipers can lead to catastrophic brake failure, potentially resulting in serious accidents. Understanding the safety implications and adhering to best practices is crucial for ensuring the reliable operation of the braking system.

Importance of Proper Installation and Maintenance

Correct installation of brake calipers is vital to ensure consistent braking performance and avoid potential hazards. Improper installation can lead to uneven pad wear, compromised seal integrity, and ultimately, reduced braking efficiency. Regular maintenance, including inspecting for leaks, corrosion, and proper pad thickness, is equally important to maintain the system’s functionality and reliability. Failure to address these issues can compromise the braking system’s ability to stop the vehicle effectively.

Safety Precautions During Repair and Replacement

Safety precautions are paramount during brake caliper repair and replacement. These procedures involve working with pressurized hydraulic systems and potentially hazardous materials. Ensuring proper personal protective equipment (PPE) is essential, such as safety glasses, gloves, and appropriate clothing. Furthermore, disconnecting the brake lines and hydraulic components requires careful handling to prevent fluid leaks and potential contamination. Adequate ventilation is crucial in the workspace to mitigate exposure to potentially harmful substances during the repair process.

Strict adherence to manufacturer’s instructions for disconnecting and reconnecting brake lines and components is essential to avoid compromising the system’s safety.

Recommendations for Maintaining Safe Braking Systems, Brake calipers

Maintaining a safe braking system involves a combination of regular inspections and adherence to recommended maintenance schedules. A critical aspect of this is inspecting the brake calipers for any signs of wear, damage, or fluid leaks. Regular brake fluid changes, in accordance with the vehicle manufacturer’s recommendations, are crucial to maintaining hydraulic system integrity. Using only the specified brake caliper components and pads ensures proper fit and function.

Moreover, timely replacement of worn brake components, including calipers, pads, and rotors, is crucial for safe braking performance. Properly disposing of waste materials and ensuring compliance with environmental regulations are essential parts of safe braking system maintenance.

Visual Inspection Checklist for Brake Calipers

Regular visual inspections are essential for identifying potential issues early on. This checklist provides a structured approach to ensure the thorough examination of brake calipers:

- Inspect for any signs of leaks or fluid pooling around the caliper. Leaks can indicate a damaged seal or a compromised component, necessitating immediate attention to prevent brake failure.

- Check for corrosion on the caliper body or mounting points. Corrosion can weaken the caliper’s structure, affecting its performance and potentially causing failure.

- Examine the brake pads for wear and tear. Adequate pad thickness is critical for effective braking. Worn pads should be replaced promptly to ensure safe braking.

- Inspect the caliper pistons for proper alignment and movement. Any misalignment or sticking pistons can affect the caliper’s function and necessitate repair or replacement.

- Look for damage to the caliper mounting brackets. Any damage to these brackets can compromise the caliper’s secure attachment to the vehicle, potentially leading to safety hazards.

Closing Notes

In conclusion, brake calipers are critical for vehicle safety. Proper maintenance, understanding of different types, and recognition of potential issues are vital for optimal performance and prolonged lifespan. This guide has explored the key aspects of brake calipers, from their design and function to their crucial role in vehicle safety. We’ve covered everything from the fundamental components to advanced engineering considerations.

Remember, proper maintenance and care are essential to ensure safe and effective braking.

Expert Answers

What are the common causes of brake caliper squeaking?

Squeaking brakes often result from worn brake pads, a lack of lubrication, or rust buildup on the caliper components. Proper lubrication and pad replacement can resolve the issue.

How often should brake calipers be inspected?

Regular inspections, at least annually or more frequently depending on driving conditions and vehicle usage, are recommended to detect potential issues early on.

What are the typical signs of brake caliper wear?

Signs of wear include squeaking, dragging sounds during braking, reduced braking performance, and visible wear on the caliper components. Any unusual noise or reduced braking power should prompt immediate inspection.

What are the safety precautions when replacing a brake caliper?

Safety precautions include ensuring the vehicle is securely supported, using appropriate tools, and following proper bleeding procedures. Always consult a qualified mechanic if you’re unsure about the steps involved.