Battery health grading systems are becoming increasingly crucial in various applications, from portable electronics to electric vehicles. This guide delves into the intricacies of these systems, examining their methodologies, factors impacting battery life, and the data analysis techniques employed. We will also explore the design considerations, implementation strategies, and future trends shaping this critical field.

Understanding battery health is essential for optimizing performance, extending lifespan, and ensuring safety. This guide provides a structured approach to battery health grading systems, covering all aspects from foundational principles to emerging technologies.

Introduction to Battery Health Grading Systems

Battery health grading systems provide a standardized way to evaluate the performance and remaining capacity of rechargeable batteries. This assessment is crucial for ensuring optimal device operation and predicting the lifespan of the battery. The systems account for factors like capacity degradation, internal resistance changes, and cycle life, providing a numerical representation of the battery’s overall health.Understanding battery health is vital across a wide range of applications, from consumer electronics to electric vehicles.

Accurate assessments allow for proactive maintenance, optimized usage, and informed replacement decisions, ultimately improving efficiency and extending the operational life of the battery-powered devices.

Battery Health Assessment Methods

Various methods are employed to evaluate battery health. These methods can range from simple discharge tests to sophisticated electrochemical analyses. Accurate assessment is essential for optimizing battery management and prolonging their lifespan.

- Discharge Testing: This common method involves discharging the battery under controlled conditions and measuring the capacity retained at different discharge rates. The results are then compared to the battery’s initial capacity to establish a health grade. This method is relatively straightforward and cost-effective, making it suitable for many applications.

- Cycle Life Testing: This method assesses the battery’s ability to withstand repeated charge-discharge cycles. By subjecting the battery to a predetermined number of cycles, the capacity degradation is observed, allowing for an estimation of the battery’s expected lifespan.

- Internal Resistance Measurement: Changes in internal resistance often indicate battery degradation. A higher internal resistance signifies increased energy loss during operation, impacting battery performance. Measuring this resistance provides a valuable indicator of battery health.

- Electrochemical Impedance Spectroscopy (EIS): This advanced technique employs electrochemical measurements to analyze the battery’s internal impedance. The resulting impedance spectra provide detailed insights into the battery’s internal processes, including degradation mechanisms. This sophisticated method is often employed in research and advanced applications requiring precise analysis.

Battery Types and Grading System Variations

Different battery types exhibit varying characteristics and require specific grading systems. The grading criteria reflect the unique chemical properties and performance characteristics of each battery type.

- Lithium-ion Batteries (Li-ion): Li-ion batteries are widely used in portable electronics and electric vehicles. Their grading systems often consider capacity retention, internal resistance, and cycle life. Factors like charging/discharging rate and temperature influence the grading accuracy.

- Lead-acid Batteries: These batteries, frequently used in stationary applications and some vehicles, have grading systems focused on capacity retention and voltage output. The assessment often involves examining the specific gravity of the electrolyte and the battery’s overall physical condition.

- Nickel-metal hydride (NiMH) Batteries: NiMH batteries, used in older consumer electronics, are graded primarily based on capacity retention and voltage during discharge. The aging mechanisms and the influence of temperature during operation affect the battery’s health assessment.

Comparison of Battery Health Grading Systems

The following table provides a concise overview of different battery health grading systems, highlighting their key features and differences.

| Battery Type | Key Grading Criteria | Grading Scale (Example) | Typical Applications |

|---|---|---|---|

| Lithium-ion | Capacity retention, internal resistance, cycle life, voltage, temperature | A (Excellent) to F (Poor) | Portable electronics, electric vehicles, power tools |

| Lead-acid | Capacity retention, voltage output, electrolyte specific gravity, physical condition | 1 (Excellent) to 5 (Poor) | Backup power systems, stationary storage, some vehicles |

| Nickel-metal hydride | Capacity retention, voltage during discharge, charging/discharging cycles | 1-5 stars | Consumer electronics, older portable devices |

Factors Affecting Battery Health

Battery health, a crucial aspect of portable electronic devices and electric vehicles, is significantly influenced by various factors. Understanding these factors is essential for optimizing battery performance and lifespan. Proper management of these factors can lead to extended battery life and reduced maintenance costs.

Battery health grading systems are crucial for ensuring reliable performance, especially in demanding applications like EV ambulance services. These systems need to accurately assess the condition of the battery pack to guarantee uninterrupted service during critical situations. Proper grading is vital for maintaining the safety and effectiveness of these essential vehicles.

Environmental Conditions

Environmental conditions play a critical role in battery degradation. Extreme temperatures, humidity, and exposure to harsh elements can accelerate the chemical reactions within the battery, leading to reduced capacity and shorter lifespan. For instance, leaving a lithium-ion battery in a hot car during summer can significantly degrade its performance faster than if it were stored in a cooler environment.

Moisture can also contribute to corrosion and short circuits, further impacting battery health.

Charging and Discharging Cycles

The number of charging and discharging cycles a battery undergoes is a primary determinant of its health. Each cycle contributes to a gradual reduction in the battery’s capacity. The rate of this reduction varies depending on the type of battery and the charging/discharging method. Rapid charging and deep discharging are particularly detrimental to battery health, leading to a faster rate of capacity loss compared to moderate charging and discharging.

Temperature Fluctuations, Battery health grading systems

Temperature fluctuations have a substantial impact on battery performance. Extremes of heat and cold can alter the chemical processes within the battery, leading to capacity loss and reduced cycle life. For example, storing a battery in a cold environment can make it harder to charge, while excessive heat can lead to faster capacity fade. Optimal battery performance is typically achieved within a specific temperature range.

Relationship Between Factors and Degradation

| Factor | Impact on Battery Health | Example |

|---|---|---|

| Environmental Conditions (Extreme Temperature, Humidity) | Accelerated chemical reactions, reduced capacity, shortened lifespan. | Leaving a phone in a hot car on a summer day. |

| Charging/Discharging Cycles | Gradual capacity reduction with each cycle. Rapid charging and deep discharging accelerate degradation. | Repeatedly charging and discharging a laptop battery without proper management. |

| Temperature Fluctuations | Altered chemical processes, capacity loss, reduced cycle life. | Storing a battery in a freezer or leaving it in a scorching hot car. |

Battery Health Metrics and Algorithms

Battery health grading systems rely on a set of metrics and algorithms to assess the current state of a battery. These systems aim to predict the battery’s remaining lifespan and its performance characteristics. Accurate evaluation is crucial for optimizing battery management and ensuring reliable operation in various applications.

Common Battery Health Metrics

Battery health metrics provide quantitative measures of a battery’s condition. These metrics are typically derived from measurements taken during the battery’s operational lifespan. Crucially, they reflect the degradation experienced by the battery over time. The most frequently used metrics include capacity, voltage, internal resistance, and cycle life.

- Capacity: This metric quantifies the maximum amount of energy a battery can store. A decrease in capacity indicates battery degradation. For example, a laptop battery with an initial capacity of 5000 mAh might degrade to 4500 mAh after prolonged use, reflecting a loss of energy storage capability.

- Voltage: Battery voltage is a key indicator of its state. A drop in voltage often precedes capacity loss, and the rate of voltage drop can provide insights into the degradation process. For instance, a gradual voltage decline suggests a progressive deterioration, while a sudden drop might indicate a fault.

- Internal Resistance: This parameter reflects the opposition to current flow within the battery. An increase in internal resistance signifies deterioration in the battery’s ability to deliver current, which often correlates with capacity loss. A higher internal resistance can lead to lower output current, affecting the device’s performance.

- Cycle Life: This metric tracks the number of charge-discharge cycles a battery can endure before its performance degrades significantly. Batteries typically have a specified number of cycles for which they can maintain a certain performance level. Manufacturers often specify cycle life in terms of the percentage of initial capacity maintained after a certain number of cycles.

Algorithms Employed in Battery Health Grading Systems

Various algorithms are used to process the measured metrics and estimate battery health. These algorithms are essential for converting raw data into actionable insights. Accurate prediction of battery health is paramount for efficient device operation.

- Statistical Models: These models use statistical methods like regression analysis to establish relationships between the measured metrics and the battery’s remaining lifespan. These models can be employed to predict the battery’s future performance based on past data. For example, a linear regression model can estimate capacity degradation based on the number of charge-discharge cycles. This method is useful for estimating remaining battery life under normal operating conditions.

- Machine Learning Algorithms: These sophisticated algorithms can analyze complex patterns in the battery’s behavior and predict future performance more accurately. For instance, neural networks can learn from a large dataset of battery performance data, identifying subtle patterns that might be missed by simpler models, allowing more precise estimations of battery degradation.

Determining Battery Capacity and Remaining Life

Battery capacity and remaining life are crucial components of battery health assessments. Calculating these values is based on the collected metrics and the employed algorithms.

- Capacity Calculation: Battery capacity is typically determined by measuring the total charge that the battery can store. The capacity is expressed in units such as milliampere-hours (mAh) or watt-hours (Wh). A common formula used to estimate capacity is the integral of current over time during a discharge test.

- Remaining Life Calculation: Estimating remaining life involves projecting the future degradation of the battery based on the measured metrics and the chosen algorithm. Mathematical models are used to predict how capacity will decline over time. Examples of such models include linear, exponential, or sigmoid decay models.

Remaining life = (Initial Capacity – Current Capacity) / (Rate of Capacity Degradation per Cycle)

The rate of degradation depends on factors such as usage patterns, temperature, and environmental conditions.

Examples of Mathematical Models

Different mathematical models are used to estimate battery capacity and remaining life. These models vary in their complexity and accuracy.

| Model Type | Description | Formula (Example) |

|---|---|---|

| Linear Decay | Assumes a constant rate of capacity loss over time. | Capacity = Initial Capacity – (Rate of Degradation – Time) |

| Exponential Decay | Assumes an exponential rate of capacity loss over time. | Capacity = Initial Capacity

|

| Sigmoid Decay | Captures the initial rapid degradation followed by a slower decline. | Capacity = Initial Capacity / (1 + e(-Rate of Degradation – Time)) |

Data Collection and Analysis Techniques

Effective battery health grading relies heavily on accurate data collection and sophisticated analysis. This involves employing various methods to capture performance indicators, followed by rigorous analysis to derive meaningful health metrics. Proper interpretation of these metrics is crucial for accurate grading and ultimately, informed decision-making regarding battery management.

Battery health grading systems are crucial for accurately assessing a vehicle’s power source. These systems, often integrated with over-the-air car firmware updates, allow for real-time monitoring and prediction of battery performance. The constant data gathering and analysis enabled by over-the-air car firmware ultimately improves the reliability and longevity of battery health grading systems, making them more effective tools for vehicle maintenance.

Methods for Collecting Battery Performance Data

Data collection is the cornerstone of any battery health assessment. Various methods are available, each with its own strengths and limitations. These methods often complement each other, providing a more comprehensive understanding of the battery’s condition.

- Cyclic Testing: This method involves subjecting the battery to repeated charge-discharge cycles under controlled conditions. The number of cycles completed, along with the associated voltage, current, and temperature data, provides valuable insight into the battery’s capacity retention and degradation over time. For example, a battery exhibiting a significant capacity drop after a certain number of cycles indicates potential degradation.

Monitoring the voltage profile during each cycle can pinpoint specific degradation patterns.

- Real-World Usage Monitoring: Real-world operating conditions often differ significantly from controlled laboratory settings. Employing sophisticated sensors embedded within the battery pack to continuously monitor parameters like voltage, current, temperature, and state of charge (SOC) during actual usage provides a more realistic assessment of the battery’s health. The collected data can then be analyzed to determine how the battery behaves under diverse load profiles.

- Accelerated Aging Tests: These tests subject the battery to more severe operating conditions than typical usage, accelerating the degradation process. This allows for quicker evaluation of the battery’s long-term health, albeit under more extreme circumstances. The resulting data provides a basis for extrapolating expected performance degradation under normal operating conditions.

Data Analysis Techniques for Battery Health Grading

Various analytical techniques are employed to process the collected data and derive battery health metrics. Choosing the appropriate technique depends on the specific data characteristics and the desired level of granularity.

- Statistical Analysis: Statistical methods, such as regression analysis, can be used to identify trends and patterns in the collected data. These trends reveal correlations between various parameters, like the number of charge-discharge cycles and the resulting capacity loss. This helps in establishing mathematical models for predicting future performance.

- Machine Learning Algorithms: Machine learning (ML) algorithms, particularly those used for classification and regression, can be highly effective in identifying patterns and predicting battery health. These models can be trained on historical data to accurately predict the remaining useful life (RUL) of the battery. ML algorithms can also help in distinguishing between different types of battery degradation. For example, a deep learning model trained on voltage and current profiles could distinguish between capacity fading and internal resistance changes.

- Data Mining Techniques: Data mining techniques can unearth hidden patterns and relationships in large datasets. By applying techniques like clustering, the battery data can be grouped into distinct classes based on similarities in their degradation characteristics. This is particularly useful in identifying potential issues with specific manufacturing batches or designs.

Interpreting Collected Data

Interpretation of the collected data is paramount in deriving meaningful insights. Data interpretation involves identifying key trends, understanding the context of the collected data, and drawing meaningful conclusions about the battery’s health.

- Trend Analysis: Plotting the collected data over time, such as the capacity retention over multiple charge-discharge cycles, reveals crucial trends in battery performance degradation. This helps to understand how the battery degrades over time. Visualizing this trend in a graph or chart allows for easy interpretation of the degradation rate and its implications.

- Comparative Analysis: Comparing the performance of different batteries under similar conditions allows for the identification of outliers and anomalies. For instance, if one battery degrades significantly faster than others, it could point towards manufacturing defects or inconsistencies in the operating conditions. This comparison is crucial for understanding the performance variability across different batteries.

Data Visualization Methods for Battery Health

Data visualization plays a crucial role in effectively communicating complex battery health data. Clear and concise visualizations make it easier to identify patterns and trends in the collected data.

- Line Graphs: Line graphs effectively visualize trends over time, such as capacity retention versus the number of cycles. These graphs highlight the degradation pattern and provide insights into the rate of capacity fading. A decreasing trend in the graph indicates a decrease in battery capacity.

- Scatter Plots: Scatter plots can be used to show the relationship between two variables, like voltage and current during discharge. These plots can highlight correlations and deviations from expected behavior, potentially revealing issues with internal resistance.

- Histograms: Histograms can display the distribution of data points, such as the variation in discharge times. This can be helpful in identifying anomalies or unusual behavior in the battery performance.

Summary Table of Data Collection and Analysis Methods

| Method | Data Collection | Data Analysis |

|---|---|---|

| Cyclic Testing | Charge/discharge cycles, voltage, current, temperature | Statistical analysis, regression models |

| Real-World Usage Monitoring | Continuous monitoring of voltage, current, temperature, SOC | Machine learning algorithms, data mining |

| Accelerated Aging Tests | Performance under extreme conditions | Statistical analysis, prediction models |

System Design Considerations for Battery Health Grading

A robust battery health grading system requires careful consideration of hardware and software components, security measures, and communication protocols. Effective design ensures accurate and reliable assessment of battery performance, enabling informed decisions regarding battery replacement or maintenance. The system must be scalable and adaptable to accommodate different battery types and applications.A well-designed system for battery health grading not only provides accurate assessments but also ensures data integrity and security.

This is crucial for preventing unauthorized access and misuse of sensitive battery performance data. Proper system design also considers communication protocols to enable seamless data transfer between different components, allowing for efficient processing and analysis.

Hardware Components for Battery Monitoring

The hardware components play a vital role in accurately capturing the critical parameters for battery health assessment. Precise measurements are essential for accurate grading, ensuring the system reflects the true state of the battery.

- Battery Management System (BMS): The BMS is a crucial component for collecting real-time data about the battery’s voltage, current, temperature, and other vital parameters. It acts as the primary interface for acquiring critical data.

- Sensors: Various sensors, such as temperature sensors, voltage sensors, and current sensors, are integrated into the system to monitor the battery’s physical conditions and electrical characteristics. Accurate sensing is paramount for precise battery health analysis. For example, temperature sensors provide critical information on battery temperature, which significantly impacts battery performance and lifespan.

- Data Acquisition System (DAQ): The DAQ acts as a bridge between the sensors and the data processing units. It digitizes the analog signals from the sensors, enabling the software components to interpret and utilize the data.

Software Components for Data Analysis and Grading

The software components are responsible for processing the raw data acquired from the hardware, performing the necessary calculations, and ultimately providing a health grade.

- Data Processing Algorithms: Sophisticated algorithms are implemented to calculate battery health metrics based on the collected data. These algorithms must be robust to ensure accurate grading across various battery types and operating conditions.

- Battery Health Models: These models are essential for correlating the measured data with established battery degradation patterns. The models help predict future battery performance and provide a more comprehensive evaluation.

- Grading System: A well-defined grading system is critical for standardizing the health assessment process. The system should clearly define thresholds and categories to classify battery health levels.

- User Interface (UI): A user-friendly interface is necessary for presenting the battery health assessment results. The UI should be intuitive and provide clear visualizations of the data.

Security Measures for Data Protection

Security measures are essential for protecting sensitive battery data from unauthorized access and malicious activities.

- Data Encryption: Encrypting data transmission and storage is crucial to prevent unauthorized access. Strong encryption protocols, like AES-256, are essential for sensitive data protection.

- Access Control: Implementing robust access control mechanisms limits data access to authorized personnel. This can include user authentication and authorization systems.

- Data Validation: Validation procedures are necessary to ensure the integrity and accuracy of the data. These procedures help prevent data manipulation and ensure data reliability.

Communication Protocols for Data Transmission

Effective communication protocols are essential for transmitting data between various system components.

- Wireless Protocols: Wireless communication protocols like Wi-Fi or Bluetooth can be used to transmit data from the BMS to the central data processing unit.

- Wired Protocols: Wired protocols, like Ethernet, provide high-speed data transfer for real-time monitoring and analysis.

- Standardized Protocols: Using industry-standard protocols like CAN (Controller Area Network) facilitates seamless integration and interoperability with other systems.

System Architecture Diagram

The system architecture for battery health grading involves several interconnected components. A diagram illustrating the flow of data is presented below.

(Diagram illustrating the system architecture for battery health grading. The diagram would show the BMS connected to sensors, which transmit data to a DAQ. The DAQ transmits data to a central processing unit where algorithms and models are used to assess battery health. The results are then displayed on a user interface.)

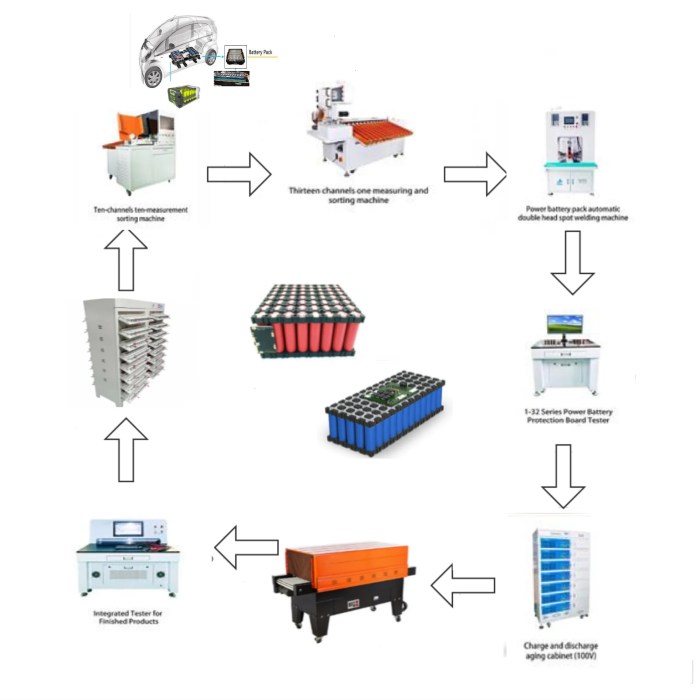

Implementation and Applications

Implementing a battery health grading system involves a multifaceted approach. Careful consideration of data acquisition methods, algorithm selection, and system integration is crucial for successful deployment. Different industries have unique needs, which necessitates tailored system configurations. The benefits of such systems are substantial, encompassing enhanced battery lifecycle management and cost savings. However, potential challenges like data reliability and system complexity must be addressed during development.

Implementation Steps

A structured approach to implementation is vital for a successful battery health grading system. Initial setup involves careful selection of hardware and software components. The system’s architecture should be scalable to accommodate future growth and evolving requirements. Data collection protocols are designed to ensure consistent and reliable measurements. This necessitates thorough testing and validation of the entire system to guarantee accurate results.

Rigorous quality assurance measures ensure that the system operates as intended. Deployment and integration into existing infrastructure are critical phases, demanding meticulous planning and execution. Finally, ongoing monitoring and maintenance are essential for optimal performance and accuracy.

Applications in Different Industries

Battery health grading systems find application across a wide spectrum of industries. The unique needs of each industry influence the specific requirements of the system. For instance, in electric vehicle (EV) manufacturing, battery health assessment is critical for performance prediction and quality control. The aerospace industry, with its focus on safety and reliability, requires stringent battery health monitoring.

Renewable energy applications, like solar energy storage, demand accurate battery health grading to ensure optimal performance and lifespan.

Advantages of Using Battery Health Grading Systems

Implementing a battery health grading system offers significant advantages. Accurate predictions of battery performance contribute to optimized maintenance strategies. Early detection of potential failures allows for timely intervention, minimizing downtime and repair costs. Enhanced battery lifecycle management translates to significant cost savings over the long term. Moreover, improved safety measures, facilitated by the system’s ability to anticipate issues, contribute to a more secure operational environment.

Ultimately, these systems lead to increased operational efficiency and reduced environmental impact.

Potential Challenges in Implementation

Implementing a battery health grading system presents several challenges. Data acquisition methods must be reliable and consistent to ensure accurate results. The complexity of battery chemistry and operating conditions can complicate data analysis and algorithm development. System integration into existing infrastructure can pose significant challenges, requiring careful planning and execution. Ensuring data security and privacy is paramount, particularly in sensitive applications.

Maintaining system accuracy and reliability over time requires continuous monitoring and updates.

Applications Table

| Application Area | Specific Requirements |

|---|---|

| Electric Vehicles (EVs) | High-speed data acquisition, real-time performance monitoring, integration with vehicle control systems. |

| Renewable Energy Storage | Long-term performance prediction, robust data analysis, integration with grid management systems. |

| Aerospace | Extreme environment handling, high-precision data analysis, safety-critical system integration. |

| Portable Electronics | Compact design, low power consumption, user-friendly interface for battery status display. |

| Industrial Machinery | Predictive maintenance, long-term operational stability, robust system integration with existing control systems. |

Standards and Regulations

Battery health grading systems are crucial for ensuring the safety, reliability, and performance of batteries in various applications. However, the accuracy and consistency of these systems need to be validated and regulated to prevent potential misuse and ensure consumer protection. This section explores the critical standards and regulations that govern battery health grading, examining the specific frameworks used in different industries and the legal implications of these systems.

Relevant Standards and Regulations

Battery health grading systems are increasingly subject to industry-specific standards and regulations. These standards define the methodologies, testing procedures, and reporting requirements for assessing battery health. Compliance with these standards is vital for maintaining the quality and safety of battery products.

Key Standards Used in Different Industries

Various industries have adopted specific standards for battery health grading. Automotive manufacturers often use standards like SAE J2985 for battery testing, while in the energy storage sector, standards like IEC 62619 for lithium-ion batteries are commonly used. These standards provide a framework for comparing and evaluating battery performance across different manufacturers and applications.

- Automotive Industry: SAE J2985 is a crucial standard for battery testing and performance evaluation in vehicles. It defines various test procedures for determining battery health, including discharge and charge cycles, temperature cycling, and calendar aging. This standard is vital for ensuring consistent performance and safety in electric vehicles.

- Energy Storage: IEC 62619 is a significant standard for lithium-ion batteries used in energy storage systems. It specifies requirements for safety, performance, and testing, covering areas like thermal runaway behavior, capacity degradation, and cycle life. Adherence to these standards ensures the reliable and safe operation of energy storage systems.

- Portable Electronics: While not a single, universally recognized standard, the industry often relies on manufacturer-specific guidelines and quality control procedures. These focus on capacity retention and cycle life, typically with specific requirements based on the intended product use.

Legal Implications of Battery Health Grading Systems

Accurate and transparent battery health grading systems are essential for avoiding legal disputes. Misrepresentation of battery health can lead to product liability issues and reputational damage. Strict adherence to established standards and regulations is paramount for avoiding legal challenges and ensuring consumer trust.

Certification Procedures for Battery Health Grading Systems

Certification procedures vary based on the industry and specific standards. Manufacturers may need to undergo rigorous testing and evaluation to obtain certifications for their battery health grading systems. Third-party testing laboratories often play a critical role in ensuring the accuracy and validity of the certification process.

Regulatory Frameworks in Different Countries or Regions

Different countries and regions have varying regulatory frameworks for battery health grading. For example, some regions might have stricter regulations regarding the reporting and disclosure of battery health information. These regulations reflect specific safety and consumer protection concerns within each jurisdiction.

Future Trends and Innovations: Battery Health Grading Systems

Battery health grading systems are constantly evolving to keep pace with advancements in battery technology. Emerging trends in battery chemistry, manufacturing processes, and monitoring techniques are driving the need for more sophisticated and accurate grading methods. This section explores these evolving trends and their implications for the future of battery health management.

Emerging Battery Technologies

The development of next-generation battery chemistries, such as solid-state batteries and lithium-sulfur batteries, is significantly impacting battery health grading systems. These newer chemistries often exhibit unique degradation patterns compared to traditional lithium-ion batteries. Consequently, current grading algorithms may need adjustments or entirely new models to accurately assess the health of these novel cells. For example, the higher operating temperatures and different electrochemical processes in solid-state batteries necessitate specific monitoring strategies to detect and quantify degradation.

Innovations in Battery Health Monitoring

Innovative monitoring techniques are being developed to improve the accuracy and efficiency of battery health assessment. These advancements include the integration of advanced sensors, such as those measuring internal cell temperature, voltage, and impedance, into battery packs. By capturing more comprehensive data, battery health grading systems can potentially predict degradation more accurately. The development of advanced signal processing algorithms to extract valuable insights from these measurements will be crucial.

This will lead to more reliable prognostics, enabling proactive maintenance and minimizing downtime.

AI and Machine Learning in Grading Accuracy

Artificial intelligence (AI) and machine learning (ML) are poised to revolutionize battery health grading. AI models, trained on large datasets of battery performance data, can identify complex patterns and relationships that may be missed by traditional methods. This capability enables the development of predictive models that forecast battery lifespan and degradation more precisely. For example, AI-powered systems can analyze historical data on various battery types and operating conditions to create a detailed profile for each battery, enabling more accurate health predictions.

These models can also learn from real-time data to adapt to varying operating conditions, ensuring a dynamic and responsive assessment.

Advanced Sensors and Data Analytics

Advanced sensors, such as those capable of measuring internal cell temperatures and voltages with high precision and resolution, are essential to acquiring detailed data for accurate battery health grading. Combined with sophisticated data analytics, this approach can reveal nuanced degradation patterns that would be difficult to identify using simpler techniques. Furthermore, the data analysis process needs to handle large volumes of complex data generated from these sensors, enabling efficient and accurate insights into the battery health status.

The insights can further guide the development of targeted maintenance strategies and optimization approaches for improved battery performance.

Summary of Emerging Trends

The future of battery health grading systems hinges on embracing emerging battery technologies, innovative monitoring techniques, and the application of AI and machine learning. By incorporating advanced sensors, comprehensive data analysis, and AI-powered models, grading systems will become more sophisticated, accurate, and predictive, enabling more efficient and sustainable battery management. These advancements will ultimately lead to longer battery lifespans and lower operational costs for various applications.

Case Studies of Battery Health Grading Systems

Real-world implementations of battery health grading systems offer valuable insights into their practical application, performance, and limitations. Examining these case studies helps to understand the nuances of implementing such systems in diverse scenarios and the key factors that contribute to their success or failure. These studies demonstrate the importance of carefully considering factors such as data acquisition methods, algorithm selection, and system integration to achieve accurate and reliable battery health assessments.

Examples of Battery Health Grading Systems

Various industries have deployed battery health grading systems. Electric vehicle manufacturers, for instance, often integrate such systems to monitor the performance of battery packs in their vehicles. Renewable energy companies use similar systems to assess the health of batteries in energy storage systems. These systems are tailored to the specific requirements and characteristics of the batteries being monitored.

Features and Functionalities of Existing Systems

Different systems employ various features and functionalities. Some systems focus on monitoring specific battery parameters like voltage, current, and temperature. Others incorporate advanced algorithms to predict future battery performance and degradation. The data collected is typically analyzed to generate a health score or a detailed report on the battery’s current condition. Advanced systems might even predict remaining useful life (RUL) based on historical data and performance trends.

These features can include sophisticated signal processing techniques to identify anomalies and subtle degradation patterns, and incorporate machine learning models for enhanced prediction accuracy.

Performance and Effectiveness

The effectiveness of battery health grading systems varies depending on several factors. The accuracy of the system depends on the quality and completeness of the data being collected, the reliability of the algorithms used for analysis, and the design of the system architecture. Some systems have demonstrated high accuracy in predicting battery degradation, while others may have shown limitations in certain conditions or specific battery chemistries.

In general, systems utilizing comprehensive data collection and robust algorithms tend to achieve higher accuracy and better predictive capabilities.

Lessons Learned from Implementations

Analysis of existing systems reveals several important lessons. The choice of data collection method significantly impacts the system’s accuracy. The design of the data acquisition system needs to be carefully considered to minimize noise and ensure reliable measurements. Selecting the appropriate algorithm for analyzing battery data is crucial. Choosing algorithms that are suitable for the specific battery chemistry and operational conditions is important.

Integration with other systems, such as vehicle control systems or energy management systems, needs careful consideration to avoid conflicts and ensure seamless operation.

Table of Case Studies

| Case Study | Industry | Key Features | Performance | Lessons Learned |

|---|---|---|---|---|

| Electric Vehicle Battery Management System (EVBMS) | Automotive | Real-time monitoring of voltage, current, and temperature; predictive maintenance algorithms | High accuracy in predicting battery degradation, leading to improved vehicle reliability | Importance of data integrity and algorithm validation for accurate predictions |

| Renewable Energy Storage System (RESS) | Renewable Energy | Monitoring battery cycles and environmental conditions; advanced degradation models | Improved capacity utilization and reduced downtime for energy storage systems | Need for robust data acquisition systems to handle fluctuating environmental conditions |

| Portable Electronic Device Battery Management | Consumer Electronics | Reduced battery discharge time and enhanced battery life through intelligent management | Improved user experience and reduced device downtime | Balancing battery performance with device form factor and cost |

Closure

In conclusion, battery health grading systems are vital for maintaining optimal battery performance and longevity across diverse industries. The methods, factors, and considerations presented in this guide provide a comprehensive framework for understanding and implementing these systems effectively. Future advancements in battery technology and data analytics promise to further enhance the precision and efficiency of these systems.

FAQ Corner

What are the most common battery types used in these systems?

Lithium-ion batteries are prevalent, but other types like nickel-metal hydride and lead-acid batteries are also used, each with its own grading system variations.

How do environmental conditions affect battery health?

Temperature fluctuations, humidity, and exposure to extreme temperatures significantly impact battery performance and lifespan.

What are some typical data visualization methods for battery health data?

Line graphs, bar charts, and heatmaps are common methods for visualizing battery health data, aiding in understanding trends and patterns.

What are the security concerns associated with battery health grading systems?

Data security is paramount. Robust encryption, access controls, and data protection protocols are crucial for safeguarding sensitive battery performance information.