Ceramic coating offers a durable and protective layer for various surfaces. This guide delves into the specifics of ceramic coatings, exploring their composition, types, benefits, and applications across industries. From automotive to architectural use, we’ll uncover the advantages and considerations related to this advanced coating technology.

Understanding the different types of ceramic coatings, like nano-ceramic and hybrid, is crucial. This section will Artikel their respective properties, applications, and performance characteristics, enabling a deeper understanding of their unique strengths.

Introduction to Ceramic Coatings

Ceramic coatings are thin, protective layers applied to surfaces to enhance their properties. These coatings offer superior resistance to various environmental factors, including abrasion, chemicals, and heat. Their durability and longevity make them a popular choice in diverse industries.Ceramic coatings are engineered with specific chemical compositions and manufacturing processes to achieve desired properties. Their applications range from automotive finishes to industrial equipment protection, showcasing their versatility and performance advantages.

Chemical Composition of Ceramic Coatings

Common ceramic coatings are composed primarily of metal oxides, such as silica (SiO2), alumina (Al2O3), and zirconia (ZrO2). These oxides, often combined with other elements, form a hard, durable, and corrosion-resistant layer. The specific composition influences the coating’s properties, such as its hardness, adhesion, and resistance to heat. For example, a coating rich in silica might exhibit high transparency, while one with a higher alumina content might be more resistant to scratching.

Types of Ceramic Coatings

Ceramic coatings come in various forms, tailored to specific applications. Nano-ceramic coatings, a popular type, utilize nanoparticles to achieve exceptional hardness and durability. Hybrid ceramic coatings combine ceramic materials with other polymers or resins, offering a balance of properties, often at a more accessible price point. The choice of coating type depends on the desired balance of performance and cost.

Manufacturing Processes for Ceramic Coatings

The manufacturing processes for ceramic coatings vary depending on the desired properties and application. One common method involves plasma spraying, where a ceramic material is melted and sprayed onto the substrate in a controlled plasma environment. Another approach is chemical vapor deposition (CVD), where a chemical reaction in a controlled environment creates a thin ceramic film on the surface.

Different manufacturing techniques influence the final coating properties, such as thickness, uniformity, and adhesion.

Comparison of Ceramic Coating Types

| Type | Properties | Applications | Advantages |

|---|---|---|---|

| Nano-ceramic | Exceptional hardness, high durability, enhanced scratch resistance, excellent chemical resistance, superior heat resistance. | Automotive coatings, industrial equipment protection, high-performance sports equipment, cutting tools, and high-precision machinery parts. | Superior scratch and wear resistance compared to other coatings. Offers exceptional protection in harsh environments. |

| Hybrid | Balanced properties, good hardness and durability, often more affordable than pure ceramic coatings, good adhesion. | Automotive refinishing, marine applications, architectural coatings, and various industrial applications requiring a balance of cost and performance. | Offers a cost-effective alternative to nano-ceramic coatings while maintaining acceptable levels of performance. Provides a broader range of applications. |

Applications of Ceramic Coatings

Ceramic coatings, renowned for their exceptional properties, find diverse applications across various industries. Their hardness, chemical resistance, and low friction characteristics make them ideal solutions for enhancing the performance and longevity of numerous products and surfaces. From automotive components to high-tech electronics, the versatility of ceramic coatings is truly remarkable.

Automotive Applications

Ceramic coatings are increasingly popular in the automotive sector. Their ability to provide a durable, protective layer significantly improves the appearance and longevity of vehicles. This is achieved through enhanced resistance to scratches, UV degradation, and environmental contaminants. Furthermore, the low-friction properties of some ceramic coatings can contribute to improved fuel efficiency by reducing drag.

Aerospace Applications, Ceramic coating

The aerospace industry leverages ceramic coatings for their exceptional thermal resistance and corrosion resistance. These coatings are crucial in high-temperature environments, protecting critical components from extreme heat and wear. For instance, ceramic coatings are employed in jet engines and other high-performance aircraft parts, where durability and thermal protection are paramount.

Industrial Applications

Ceramic coatings find broad application in various industrial settings. Their resistance to abrasion, corrosion, and high temperatures makes them suitable for numerous industrial components and equipment. This includes machinery parts, industrial furnaces, and pipelines. These coatings offer significant cost savings by extending the lifespan of equipment and reducing maintenance requirements.

Architectural and Decorative Applications

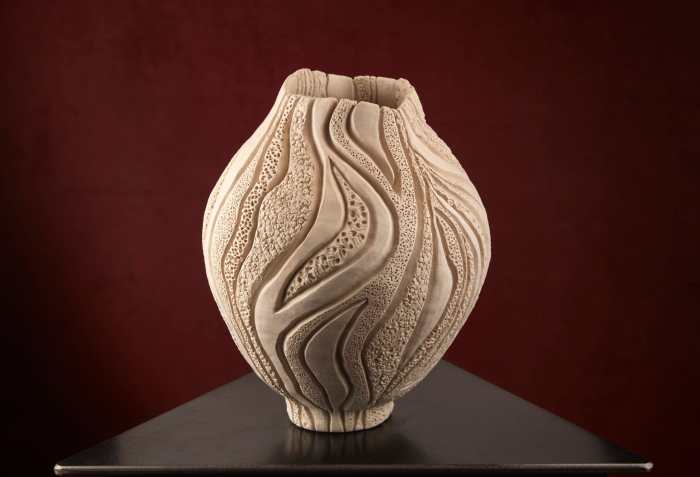

Beyond functional applications, ceramic coatings are also utilized in architectural and decorative settings. They can enhance the aesthetic appeal of buildings and other structures by providing a durable, protective, and visually appealing surface finish. This is achieved through various colors and finishes, enhancing the overall design. In certain applications, the reflective properties of specific ceramic coatings can also reduce the need for external lighting.

Electronics Applications

In the electronics industry, ceramic coatings are employed to protect components from corrosion and degradation. Their high dielectric strength and electrical insulation properties are crucial in enhancing the reliability and longevity of electronic devices. Furthermore, these coatings can improve the heat dissipation of electronic components, thereby preventing overheating and ensuring optimal performance.

Products Utilizing Ceramic Coatings

- Automotive parts (e.g., bumpers, wheels, engine components)

- Aerospace components (e.g., engine parts, aircraft structures)

- Industrial machinery (e.g., gears, bearings, pipes)

- Architectural coatings (e.g., building facades, decorative elements)

- Electronic components (e.g., circuit boards, connectors)

- Cutting tools (e.g., drill bits, milling cutters)

The above list showcases a sampling of the wide array of products and components that benefit from the application of ceramic coatings. The diverse range of applications reflects the versatility and importance of these coatings in modern manufacturing and construction.

Performance Characteristics

Ceramic coatings exhibit a range of performance characteristics that make them suitable for diverse applications. These characteristics are crucial in determining their effectiveness and longevity. Their exceptional resistance to various environmental factors and high-temperature tolerance are key advantages.

Impact of Temperature

Ceramic coatings demonstrate varying degrees of thermal stability depending on their composition. Some formulations can withstand extremely high temperatures, while others are more suitable for moderate heat environments. This temperature tolerance is vital in applications requiring resistance to heat-related degradation or damage. The ability of a coating to withstand extreme temperatures is influenced by its chemical structure and the specific ceramic materials used in its creation.

Different ceramic materials have varying melting points and thermal expansion coefficients, leading to variations in performance at different temperatures.

Resistance to UV Radiation and Weathering

Ceramic coatings often exhibit superior resistance to ultraviolet (UV) radiation and weathering compared to traditional paints or coatings. This resistance is a consequence of the high chemical stability and inherent strength of the ceramic materials. UV radiation and weathering can cause degradation in many materials, including the fading or cracking of organic coatings. Ceramic coatings, however, are less susceptible to these effects, ensuring longer-lasting protection for the underlying surface.

The precise resistance depends on the specific formulation and the presence of UV stabilizers.

Ceramic coating offers a robust layer of protection, but it’s also crucial to consider the performance brake pads you use. High-performance brake pads, like those available at performance brake pads , can generate intense heat during braking, which can potentially impact the integrity of the coating. Choosing the right combination ensures optimal performance and longevity for your vehicle’s protective ceramic coating.

Performance in Various Environments

Ceramic coatings demonstrate excellent performance in diverse environments. Their high chemical resistance makes them suitable for applications involving exposure to harsh chemicals, moisture, or corrosive substances. Their ability to withstand extreme temperatures is also valuable in high-heat environments. In summary, their performance in various environments is directly related to the specific ceramic composition and the manufacturing process.

Consider applications in industrial settings, where chemical exposure is common, or in automotive parts exposed to high temperatures and UV radiation.

Thermal Conductivity and Heat Resistance

The thermal conductivity of a ceramic coating directly impacts its ability to conduct heat away from the underlying surface. Lower thermal conductivity values indicate better heat resistance. Heat resistance is a critical factor in many applications, such as protecting components from excessive heat or preventing heat transfer to sensitive parts. The choice of ceramic coating depends on the specific thermal requirements of the application.

Different types of ceramic coatings have different thermal conductivities and heat resistance capabilities.

Comparison of Ceramic Coating Types

| Ceramic Coating Type | Thermal Conductivity | Heat Resistance | UV Resistance |

|---|---|---|---|

| Nano-ceramic | Generally low, often < 1 W/mK | Excellent, high melting points of constituent materials | Very high, due to the dense structure and chemical stability |

| Hybrid | Intermediate, depending on the blend of materials | Good, often a balance between high-temp and cost | High, but may vary based on the specific hybrid formulation |

Note: Values for thermal conductivity and heat resistance are approximate and may vary depending on the specific formulation and manufacturing process. UV resistance is typically very high for all ceramic coatings, but specific values depend on the type of UV protection incorporated in the formula.

Installation and Application Procedures

Proper installation of ceramic coatings is crucial for achieving the desired protective and aesthetic outcomes. Careful attention to surface preparation, application methods, and curing times ensures optimal performance and longevity. Variations in coating types necessitate tailored application strategies.

Surface Preparation

Thorough surface preparation is paramount to the success of a ceramic coating application. A clean, smooth, and contaminant-free surface maximizes adhesion and prevents premature degradation of the coating. This entails meticulous removal of existing contaminants, such as dirt, grease, waxes, and previous coatings. The surface should be free of imperfections like rust, pitting, or loose paint, which can hinder the coating’s ability to bond effectively.

Adhesion promoters, if recommended by the coating manufacturer, are often used to enhance the bond between the coating and the substrate.

Application Methods

Diverse methods are available for applying ceramic coatings, each with its own advantages and limitations. The chosen method often depends on the surface area, complexity of the design, and the specific coating formulation.

- Spray Application: This method involves atomizing the coating into a fine mist, which is then sprayed onto the surface. Spray application is suitable for large areas and provides a relatively uniform coating. Careful attention to spray pressure, distance, and nozzle type is essential for achieving optimal coverage and preventing uneven thickness.

- Dip Application: This technique is particularly useful for applying coatings to parts with complex shapes. The part is submerged into a container of the coating, allowing the coating to adhere to the surface. The dip method can lead to uneven coating thickness if not carefully controlled, demanding precise immersion times and withdrawal methods.

- Manual Application: For smaller or more intricate surfaces, a manual application method, like a brush or applicator, may be more appropriate. Manual application allows for precise control over the coating application, enabling targeted coverage of areas requiring extra attention. However, it can be time-consuming for large areas.

Curing and Drying Times

Curing and drying times are critical factors influencing the final performance of the ceramic coating. Different ceramic coatings have varying curing requirements, and exceeding or falling short of these times can compromise the coating’s durability and effectiveness. These times are influenced by factors like temperature, humidity, and the specific coating composition.

Ceramic coating is a fantastic way to protect surfaces, and its durability is key. Imagine the potential for this kind of protection on robotic delivery pods, like the ones being developed and tested now, robotic delivery pods. This kind of coating could significantly extend the lifespan of these important delivery systems, making them even more reliable for the future.

Ultimately, ceramic coating offers a significant advantage in various applications, from everyday vehicles to innovative delivery systems.

| Ceramic Coating Type | Curing Time (Approximate) | Drying Time (Approximate) |

|---|---|---|

| Type A | 24-48 hours | 1-2 hours |

| Type B | 12-24 hours | 30-60 minutes |

| Type C | 48-72 hours | 2-4 hours |

Note: These are approximate times and may vary depending on the specific conditions. Always consult the manufacturer’s instructions for precise curing and drying guidelines.

Step-by-Step Guide for Applying Ceramic Coatings

- Thoroughly clean the surface, removing any contaminants.

- If necessary, apply an adhesion promoter according to manufacturer’s instructions.

- Select the appropriate application method (spray, dip, or manual).

- Apply the coating in thin, even layers, ensuring complete coverage.

- Allow the coating to cure according to the manufacturer’s recommendations.

- Avoid touching the coated surface until it has fully cured.

Comparison with Other Coating Technologies

Ceramic coatings offer a compelling alternative to traditional paint and other coating methods. Their unique properties, including exceptional hardness, chemical resistance, and durability, often surpass those of competing technologies. This comparison explores the advantages and disadvantages of ceramic coatings relative to other popular coating options.Ceramic coatings stand out due to their exceptional performance characteristics. However, their cost-effectiveness and suitability for specific applications should be considered alongside alternative coating technologies.

Understanding these comparisons allows informed decisions on the most appropriate coating for a given project.

Comparison Table

The following table provides a comparative overview of ceramic coatings versus other common coating technologies.

| Coating Technology | Pros | Cons | Applications |

|---|---|---|---|

| Ceramic Coating | High hardness and scratch resistance, excellent chemical resistance, superior durability, enhanced corrosion protection, low friction coefficient, potentially improved fuel efficiency (in automotive applications), and aesthetic appeal. | Higher initial cost compared to some alternatives, specialized application procedures, limited availability of specific colours or finishes. | Automotive parts (e.g., engine components, exhaust systems), industrial machinery, architectural coatings, tools, and consumer products. |

| Epoxy Coatings | Relatively low cost, good adhesion to various substrates, readily available in various colours and finishes, wide range of application methods. | Lower hardness and scratch resistance than ceramic coatings, moderate chemical resistance, limited durability compared to ceramic coatings, potential for chipping or cracking. | Industrial flooring, metal parts, wood surfaces, and other general protective coatings. |

| Powder Coatings | Excellent corrosion resistance, durable, good aesthetic appeal, high build rate, can be applied to complex shapes. | Requires specialized application equipment, potential for uneven coatings on complex surfaces, lower chemical resistance compared to ceramic coatings. | Metal furniture, appliances, and automotive parts. |

| Polymer Coatings | Cost-effective, wide variety of colours and finishes, ease of application. | Lower durability and chemical resistance compared to ceramic coatings, susceptible to scratching and abrasion, limited resistance to extreme temperatures. | General protective coatings for wood, metal, and plastic surfaces. |

Advantages of Ceramic Coatings

Ceramic coatings exhibit a range of advantages over other coating technologies, primarily due to their unique composition and structure.

- Superior Hardness and Scratch Resistance: Ceramic coatings are significantly harder than most other coating types, making them exceptionally resistant to scratches and abrasion. This translates to a longer lifespan in high-wear environments.

- Enhanced Chemical Resistance: Their chemical inertness provides superior resistance to various chemicals, solvents, and corrosive substances, protecting substrates from damage in demanding environments.

- Exceptional Durability: The inherent strength and hardness of ceramic coatings contribute to their exceptional durability. They can withstand extreme temperatures and mechanical stresses, making them suitable for high-performance applications.

- Low Friction Coefficient: Ceramic coatings often possess a lower coefficient of friction, reducing wear and tear and potentially improving energy efficiency in moving parts.

Disadvantages of Ceramic Coatings

Despite their many benefits, ceramic coatings do have some drawbacks compared to other technologies.

- Higher Initial Cost: The advanced manufacturing processes and materials used in ceramic coatings often lead to a higher initial cost compared to more conventional coatings.

- Specialized Application Procedures: Applying ceramic coatings effectively often requires specialized equipment and techniques, which can increase the overall project cost and time.

- Limited Color Options: Currently, the range of available colors and finishes for ceramic coatings might be more limited compared to some other coating options.

Situations Where Ceramic Coatings Excel

Ceramic coatings demonstrate significant advantages in specific situations.

- High-Performance Automotive Applications: The low friction and high-temperature resistance make ceramic coatings ideal for engine components and exhaust systems, potentially improving fuel efficiency and reducing wear.

- Industrial Machinery: The enhanced corrosion resistance and hardness of ceramic coatings make them suitable for components in harsh industrial environments, extending the lifespan of machinery.

- Architectural Coatings: Ceramic coatings’ durability and weather resistance can be advantageous in architectural applications, offering a long-lasting protective layer for buildings and structures.

Cost-Effectiveness Considerations

While the initial cost of ceramic coatings might be higher, their long-term cost-effectiveness often outweighs the upfront investment.

- Extended Lifespan: The superior durability of ceramic coatings can lead to a significantly longer lifespan for coated components, reducing the need for frequent replacements and repairs, ultimately lowering long-term costs.

- Reduced Maintenance: The enhanced resistance to wear and corrosion of ceramic coatings can significantly reduce the need for maintenance and repairs, lowering associated costs over the life cycle of the product or structure.

- Potential for Increased Efficiency: In certain applications, such as automotive parts, the low friction coefficient of ceramic coatings can contribute to improved fuel efficiency, leading to indirect cost savings.

Cost Considerations

Ceramic coatings, while offering significant performance advantages, vary considerably in pricing. Understanding the factors influencing cost is crucial for making informed decisions about their application. This section explores the pricing structure, influencing factors, cost-effectiveness, and project-specific cost considerations.The pricing of ceramic coatings is not a simple equation, and a single number doesn’t adequately represent the cost. The final price depends on several variables, making it crucial to get detailed quotes from reputable installers.

Pricing Structure of Ceramic Coatings

The pricing structure for ceramic coatings typically involves several components. A base price often reflects the type of coating, the labor associated with application, and the specific vehicle or surface being treated. Additional factors, such as the complexity of the project or the required preparation steps, will impact the overall cost. Often, add-on services, such as detailing and cleaning, will be priced separately.

Factors Influencing the Cost of Ceramic Coatings

Several key factors significantly impact the price of ceramic coatings. The type of ceramic coating material, often determined by the desired level of protection and performance, influences the price. Higher-end coatings, known for superior durability and scratch resistance, command a higher price. The size and complexity of the surface being coated directly correlate with the labor hours required.

This includes the extent of the area and any intricate shapes or difficult-to-reach areas. Installation expertise and the reputation of the application company can also affect the final price.

Cost-Effectiveness of Ceramic Coatings

Comparing ceramic coatings to alternative solutions like waxes or sealants requires a thorough analysis of long-term benefits. While the initial cost of a ceramic coating might be higher than a simple sealant, its extended lifespan and superior protection often translate into cost-effectiveness over time. The long-term protection and reduced maintenance requirements can offset the initial investment. In cases involving high-end vehicles or those requiring exceptional protection, the cost-effectiveness becomes more pronounced.

Factors Influencing the Overall Cost of a Ceramic Coating Project

Several factors directly impact the overall cost of a ceramic coating project. The condition of the vehicle’s surface, including any pre-existing damage or imperfections, plays a crucial role. Extensive prep work, like cleaning, polishing, and removing contaminants, will increase the project’s labor cost. The geographical location of the application can influence pricing due to variations in labor costs and material availability.

The choice of installer and their reputation can also impact the price, as some companies may offer competitive rates while others may command higher premiums.

Comparison of Costs of Different Ceramic Coating Types

Different ceramic coating types vary in price based on their composition, performance characteristics, and application requirements. Higher-end ceramic coatings, often boasting superior hardness and scratch resistance, typically command a higher price point compared to simpler coatings. The cost differences stem from the raw materials, the manufacturing processes, and the specialized application procedures needed for each type. The higher price is often justified by the superior long-term performance and enhanced protection.

A detailed comparison should consider the specific needs and priorities of the vehicle owner.

Environmental Impact

Ceramic coatings, while offering significant performance advantages, require careful consideration of their environmental footprint. The production process and the overall lifecycle of these coatings can have varying impacts on the environment. A comprehensive analysis of these factors is crucial for sustainable application.

Ceramic Coating Production Impacts

The manufacturing of ceramic coatings often involves high energy consumption and the use of raw materials that may have environmental implications. Specific production processes can involve the release of greenhouse gases and the generation of waste. The selection of raw materials and the energy efficiency of production facilities directly influence the environmental impact of the coating. For example, the use of environmentally friendly raw materials and energy-efficient processes can significantly reduce the carbon footprint associated with ceramic coating production.

Environmental Impact of Using Ceramic Coatings

The use of ceramic coatings can reduce the environmental impact of the coated item over its lifetime. Reduced corrosion and wear can translate into less material waste and a longer service life. However, the environmental impact of using ceramic coatings depends on factors like the specific application and the material’s lifecycle. For example, a ceramic coating applied to a vehicle part may reduce the need for replacement parts, thus lowering material consumption.

Recyclability and Reusability of Ceramic Coatings

The recyclability and reusability of ceramic coatings are still developing areas of research. Current methods may not always allow for the complete or efficient recycling of the coating. However, advancements in material science are paving the way for more sustainable practices. Some ceramic coatings might be repairable or replaceable, reducing the need for complete product replacement.

Sustainability of Ceramic Coating Materials

The sustainability of ceramic coating materials hinges on the specific raw materials used. Coatings derived from readily available, recycled, or renewable sources are more sustainable than those reliant on scarce or environmentally damaging resources. Furthermore, the use of recycled materials in coating production significantly reduces the environmental impact. For example, some ceramic coatings incorporate recycled glass, thus lowering the need for virgin material extraction.

Environmental Considerations

- Raw Material Sourcing: The environmental impact of the raw materials used in ceramic coating production varies greatly depending on their origin and extraction methods. Consideration of sustainable sourcing and the use of recycled materials is critical.

- Energy Consumption: The energy required for ceramic coating production and application processes contributes significantly to the carbon footprint. Minimizing energy consumption through efficient production processes is essential.

- Waste Generation: The generation of waste during coating production, application, and disposal should be minimized. Exploring waste reduction strategies and responsible disposal methods is critical.

- Chemical Emissions: Some ceramic coating production processes involve chemical emissions. Minimizing these emissions through the use of cleaner technologies and adherence to environmental regulations is vital.

- Lifecycle Assessment (LCA): Conducting a comprehensive LCA for ceramic coatings can provide valuable insights into the environmental impact of each stage of the coating’s lifecycle. This information allows for targeted improvements in sustainability.

- End-of-Life Management: Planning for the end-of-life management of coated products is essential. The recyclability and reusability of the coatings themselves should be considered during the design and manufacturing phases.

Future Trends and Developments

Ceramic coatings are constantly evolving, driven by advancements in materials science and the increasing demand for enhanced performance across diverse applications. The future of ceramic coatings promises even greater efficiency, durability, and functionality, opening up exciting possibilities for various industries.

Potential Advancements in Ceramic Coating Technology

Significant advancements in ceramic coating technology are anticipated, focusing on improved deposition techniques and the development of novel ceramic materials. Researchers are exploring techniques to achieve more uniform and defect-free coatings, enhancing their mechanical and thermal properties. For instance, plasma-enhanced chemical vapor deposition (PECVD) is expected to see refinements that will enable more complex geometries to be coated with greater precision.

Furthermore, the development of new ceramic compositions with tailored properties, like enhanced hardness and corrosion resistance, is a major focus. These advancements are crucial for improving the performance and longevity of coated components in harsh environments.

Future Applications of Ceramic Coatings

Ceramic coatings are poised for expansion into new applications. Their unique properties, including high hardness, low friction, and excellent thermal stability, are proving valuable in emerging sectors. One example includes their use in high-temperature components for aerospace and power generation, where they can significantly improve component lifespan. Further applications include automotive parts, particularly in enhancing the performance and durability of engine components.

The potential extends to biomedical applications, such as coatings for implants and surgical tools, owing to their biocompatibility and corrosion resistance.

Role of Nanotechnology in Ceramic Coating Innovation

Nanotechnology plays a crucial role in ceramic coating innovation. The ability to control the size and structure of ceramic nanoparticles allows for the development of coatings with enhanced properties. Nanomaterials can be incorporated into the ceramic matrix, improving the coating’s hardness, wear resistance, and adhesion. For instance, the incorporation of nano-sized ceramic particles can significantly enhance the scratch resistance of a coating.

This leads to a stronger and more resilient coating that can withstand demanding environmental conditions.

Potential for New Types of Ceramic Coatings

The exploration of new types of ceramic coatings is ongoing. Researchers are investigating novel compositions and structures to address specific performance requirements. This includes exploring hybrid ceramic coatings that combine the advantages of different ceramic materials. For instance, a coating might incorporate alumina with zirconia to achieve a balance of hardness and toughness. The development of self-healing coatings is also an exciting area of research, with potential applications in various sectors.

Overview of Emerging Trends

Several emerging trends in ceramic coatings are worth noting. One trend is the focus on environmentally friendly production methods. This includes the use of sustainable raw materials and the minimization of waste during the coating process. Another trend is the integration of advanced characterization techniques, allowing for precise control over coating properties. Finally, there is a growing interest in the development of smart coatings that respond to environmental stimuli.

These intelligent coatings could potentially adjust their properties in response to changing conditions, opening up a range of possibilities for applications.

Final Summary

In conclusion, ceramic coatings represent a significant advancement in protective surface treatments. Their exceptional durability, scratch resistance, and chemical resilience make them a compelling choice for various applications. While cost and environmental considerations play a role, the potential benefits often outweigh the drawbacks, making ceramic coatings a promising technology for the future.

FAQ Section

What are the common types of ceramic coatings?

Common types include nano-ceramic and hybrid coatings. Nano-ceramic coatings often boast enhanced properties like scratch resistance, while hybrid coatings offer a balance of features.

What are the key benefits of ceramic coatings?

Ceramic coatings excel in durability, scratch resistance, chemical resistance, and reduced maintenance requirements. They provide a protective barrier against various elements.

How much do ceramic coatings typically cost?

Cost varies significantly based on the type of coating, the surface area, and the complexity of the project. A professional estimate is advisable for accurate pricing.

What are the safety precautions when applying ceramic coatings?

Always follow the manufacturer’s instructions regarding ventilation, protective equipment (gloves, eye protection), and handling procedures. Proper ventilation is crucial to avoid inhalation of fumes.