EV noise standards are becoming increasingly important as electric vehicles (EVs) gain popularity. These standards dictate the acceptable noise levels for EVs, impacting everything from design choices to consumer perception. Understanding these regulations is crucial for manufacturers, regulators, and consumers alike.

This comprehensive guide explores the intricacies of EV noise standards, delving into their definition, impact on design, global regulations, and associated technologies. We’ll also examine consumer perception, sustainability implications, future trends, and comparisons with traditional internal combustion engine vehicles (ICEVs).

Impact on EV Design

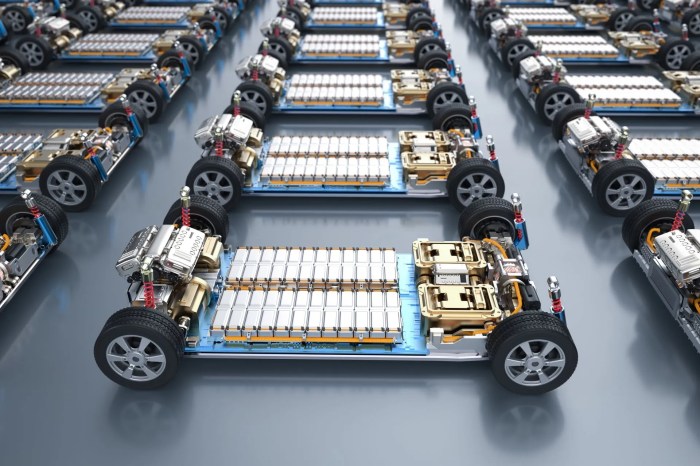

Electric vehicle (EV) noise standards are profoundly impacting the design of various components, driving innovations in motor technology, battery management, and chassis engineering. These standards, often aiming for near-silent operation, necessitate careful consideration of trade-offs between acoustic performance and other critical design factors such as cost, efficiency, and performance.Noise standards are pushing manufacturers to explore advanced materials and design techniques to minimize unwanted sounds.

This necessitates a deep understanding of the various sources of noise in EVs and their potential impact on the overall driving experience.

Motor Design Considerations

Motor design is significantly affected by noise standards. Manufacturers are increasingly incorporating sophisticated motor designs to reduce noise, vibration, and harshness (NVH). For instance, adopting specialized bearing materials and configurations can minimize friction-induced noise. Additionally, optimizing the rotor and stator designs plays a crucial role in reducing the mechanical resonances that generate audible noise. Different motor types, like induction motors and permanent magnet motors, exhibit different noise characteristics, demanding distinct design approaches.

Advanced motor control systems can also be employed to mitigate noise, enabling the motor to operate in a quieter manner under specific conditions.

Battery Pack Design

Battery pack design is another critical area influenced by noise standards. Noise arising from the movement of cells within the pack, or from thermal management systems, needs careful attention. Design choices include the use of damping materials and optimized cell arrangement to minimize vibrations. Furthermore, thermal management systems must be designed to operate without excessive noise generation, possibly by incorporating quieter fans and optimizing heat dissipation strategies.

Chassis and Body Design

Chassis and body designs are essential in reducing the transmission of noise from the components to the cabin. Manufacturers often incorporate sound-absorbing materials in the chassis and body panels. Active noise cancellation systems are increasingly used in high-end EVs to counteract noise from the motor and other sources. Employing advanced acoustic engineering principles in the design of the body structure and optimizing the airflow around the vehicle can reduce wind noise and other external sounds.

Example Design Choices

Several manufacturers are adopting innovative designs to exceed noise standards. Some examples include the use of composite materials in the chassis for better sound absorption, the integration of advanced vibration damping systems in the motor mounts, and the incorporation of acoustic liners in the cabin to isolate sound. The use of lightweight materials, like carbon fiber, can contribute to a quieter interior, although this can often come with higher costs.

Trade-offs in Design

A critical aspect of designing quieter EVs is the trade-off between noise reduction and other design considerations. While minimizing noise is paramount, designers must balance this with factors like performance, cost, and safety. For instance, reducing weight can improve acceleration and range, but heavier materials might be needed to enhance sound insulation. Similarly, advanced motor technologies might come at a higher price point compared to traditional designs.

Comparison of EV Designs

| Design | Noise Level (dB) | Motor Type | Other Features |

|---|---|---|---|

| Model A | 60 | Permanent Magnet Synchronous Motor (PMSM) | Active Noise Cancellation, Lightweight Chassis |

| Model B | 65 | Induction Motor | Sound Absorbent Materials, Optimized Cooling System |

| Model C | 58 | PMSM | Advanced Battery Packaging, Damping Materials |

Global Standards and Regulations

Global regulations surrounding electric vehicle (EV) noise are a critical aspect of ensuring both user experience and public acceptance. These standards are increasingly important as EVs become more prevalent, impacting the design and development processes for manufacturers worldwide. Differing standards across regions require careful consideration and compliance strategies to successfully navigate the global market.

Major Global Standards

Various global regions have established standards for EV noise levels, reflecting different priorities and societal contexts. These standards aim to balance the need for quieter vehicles with considerations for pedestrian safety and overall environmental harmony.

European Union Standards

The European Union (EU) has implemented stringent noise regulations for EVs, often setting the benchmark for other regions. These regulations frequently incorporate a comprehensive approach that considers various aspects of EV noise, including road noise, wind noise, and interior noise. Compliance with EU standards is crucial for EV manufacturers seeking to operate in the EU market.

United States Standards

In the United States, standards for EV noise are generally less stringent than those in the EU. However, regulations are evolving, reflecting a growing awareness of the need for quieter vehicles. This evolution in the US aligns with global trends towards lower noise levels in EVs, impacting future design choices.

Japanese Standards

Japan, known for its focus on technological innovation, also has its own set of noise standards for EVs. These standards typically reflect a balance between technological advancements and societal expectations. These standards, like those in other regions, are subject to change as EV technology advances.

Comparison and Contrast

A key difference in standards lies in the specific decibel limits for various noise categories. For example, EU standards often mandate lower noise levels for both exterior and interior sound compared to the US. This difference influences the engineering choices made by EV manufacturers when designing vehicles for different markets. Japan’s standards might fall somewhere in between, incorporating both technological considerations and societal factors.

Impact on the Global EV Market

The diversity in global EV noise standards significantly impacts the global EV market. Manufacturers must adapt their designs to meet the varying requirements of different regions, adding complexity to production processes. This necessitates a sophisticated approach to global manufacturing and distribution strategies. A successful EV manufacturer will need to consider the cost implications of adhering to various regional noise standards when determining the pricing of their vehicles in each market.

For example, a model developed to meet EU noise standards might have higher production costs than a similar model designed to meet less stringent US standards.

EV noise standards are becoming increasingly important, especially considering the growing use of electric vehicles. This also influences the development of features like vehicle to grid solutions , which could potentially alter the way we think about noise reduction strategies in the future. Ultimately, these evolving standards are key to ensuring a quieter and more sustainable future for electric transportation.

Compliance Procedures

Obtaining compliance with these standards typically involves rigorous testing and certification procedures. Manufacturers often engage independent testing laboratories to ensure their vehicles meet the specified noise levels. The specific procedures can vary by region, and manufacturers must carefully understand the requirements for each market. This includes, but is not limited to, adherence to specific testing protocols, data reporting requirements, and certification processes.

Failure to meet these standards can result in significant penalties and market restrictions.

Noise Reduction Technologies

Electric vehicles (EVs) are increasingly becoming a significant part of the transportation landscape. A key challenge in their development is minimizing noise, which impacts both the driver experience and the acoustic environment around the vehicle. Effective noise reduction strategies are crucial for wider EV adoption and a positive public perception.Various technologies are employed to address EV noise, from active noise cancellation to sophisticated material choices.

These strategies aim to reduce noise at the source, through the vehicle’s structure, and even by manipulating the surrounding environment. Understanding the nuances of these technologies is essential for optimizing EV design and meeting stringent noise standards.

Active Noise Cancellation (ANC)

Active noise cancellation (ANC) systems use microphones to detect unwanted noise and generate an opposing sound wave to cancel it out. This technique is particularly effective at reducing low-frequency noise, a common issue in EVs. High-performance ANC systems can significantly reduce the perceived noise levels, leading to a more comfortable and quieter driving experience. However, implementing effective ANC can be complex and expensive, requiring sophisticated sensors, processing units, and powerful speakers.

The effectiveness of ANC is highly dependent on the specific frequency spectrum of the noise being targeted.

Acoustic Materials and Design

The use of specialized acoustic materials in the vehicle’s body and interior plays a crucial role in noise reduction. These materials, often incorporating sound-absorbing or sound-dampening properties, are strategically placed to minimize the transmission and reflection of sound. This approach is often coupled with the careful design of the vehicle’s structure, such as optimizing the shape and material composition of panels and components.

This approach is cost-effective and relatively easy to implement, making it a popular choice for many manufacturers. The effectiveness depends heavily on the specific acoustic properties of the materials chosen and their integration into the vehicle’s design.

Engine and Transmission Noise Reduction

Modern EVs are often designed to reduce noise generated by their powertrain components. This includes improvements to the design of electric motors, gearboxes (if applicable), and other internal components. Minimizing friction and vibration within these components significantly reduces the mechanical noise produced. Advanced motor design with optimized air gaps and precision manufacturing techniques are used to lower noise levels.

These advancements, while improving efficiency and reliability, can also have a significant impact on reducing noise emissions. The effectiveness varies greatly depending on the specifics of the electric motor design.

Wheel-Related Noise Reduction

Reducing noise generated by tires and wheel bearings is another critical aspect of EV noise reduction. This can be achieved through the selection of quieter tires and advanced wheel designs that minimize friction and vibration. This approach is crucial in achieving a seamless and quiet driving experience. The effectiveness is dependent on the material properties of the tires, and the precision and quality of the wheel bearings.

It’s a crucial element of the overall noise reduction strategy.

Comparative Effectiveness of Noise Reduction Technologies

| Technique | Effectiveness | Cost | Practicality |

|---|---|---|---|

| Active Noise Cancellation (ANC) | High, particularly at low frequencies | High | Moderate, complex implementation |

| Acoustic Materials & Design | Moderate to High, dependent on material selection | Moderate | High, relatively straightforward implementation |

| Engine/Transmission Noise Reduction | High, dependent on motor design | Moderate to High | High, integrated with powertrain design |

| Wheel-Related Noise Reduction | Moderate to High, dependent on tire and bearing design | Moderate | High, integrated with wheel and tire selection |

Testing and Measurement Procedures

Standardized testing procedures are crucial for ensuring consistent and reliable evaluation of electric vehicle (EV) noise levels. These procedures allow for objective comparisons across different EV models and facilitate the identification of areas for improvement in noise reduction strategies. Accurate measurement and reporting of noise emissions are paramount for compliance with global regulations and for fostering a better understanding of EV noise characteristics.The methodologies employed for evaluating EV noise levels encompass a range of factors, including specific equipment, standardized test environments, and precise measurement parameters.

These procedures ensure the reproducibility of results, enabling comparisons between different vehicles and manufacturers, as well as allowing for objective assessment of compliance with noise emission regulations.

Standardized Test Environments

Consistent testing environments are critical for accurate noise measurements. These environments aim to minimize extraneous noise sources, such as wind and road noise, that can interfere with the evaluation of the EV’s own noise emissions. Well-defined test tracks or anechoic chambers, often with carefully controlled temperature and humidity, are employed to isolate the EV’s sound signature from external factors.

Equipment and Methodologies

Precise measurement equipment is essential for capturing accurate and reliable data. Sound level meters, calibrated to stringent standards, are used to quantify the noise levels at various points around the vehicle. Specialized microphones, strategically placed at different locations, capture the acoustic signatures. These microphones are often calibrated against known sound sources and are selected for their frequency response characteristics.

Sophisticated data acquisition systems are used to record and process the acoustic data, providing detailed noise spectra and sound pressure levels.

Parameters Measured During Tests

A comprehensive set of parameters is measured during the testing process. These parameters provide a detailed profile of the EV’s acoustic emissions, enabling a comprehensive evaluation of the noise characteristics. Measurements encompass sound pressure levels (SPL) across a wide range of frequencies, often from 20 Hz to 20 kHz. Time-domain analysis is also employed to capture transient noise events, such as engine starts and braking noises.

Other parameters like the A-weighted sound level, which is a common metric for evaluating noise perceived by humans, are also recorded. Further analysis may involve identifying specific noise sources within the vehicle through spatial analysis of the sound field.

Step-by-Step Guide for Conducting a Noise Test on an EV

- Preparation: The test vehicle is prepared by ensuring all systems are functioning correctly, and the test environment is set up according to the relevant standards. This includes ensuring the test track or chamber is free from extraneous noise sources and that the equipment is calibrated properly.

- Positioning and Placement: The vehicle is positioned according to the test specifications, with microphones strategically placed around the vehicle to capture sound from various angles and locations. Calibration of microphones is performed in accordance with established standards. This includes positioning the sound level meters and data acquisition systems to capture the data.

- Data Acquisition: The test procedures are initiated, and the data acquisition systems begin recording sound pressure levels across a range of frequencies. These data points are recorded for various operating conditions, including acceleration, deceleration, and idling.

- Data Analysis: The acquired data is processed to identify noise levels, frequency characteristics, and other parameters according to the standard procedures. The data is analyzed to determine if the vehicle meets the required noise emission standards.

- Reporting: The test results, including measured sound pressure levels and other relevant data, are documented and reported according to the specific standards and regulations.

Compliance and Certification

Successfully navigating the complexities of EV noise standards necessitates a rigorous approach to compliance and certification. This process ensures that EVs meet the established acoustic requirements, contributing to both consumer safety and environmental harmony. A robust certification procedure guarantees that EVs are not only designed to meet regulatory standards but also undergo thorough testing to confirm their compliance.Obtaining EV noise certification involves a multi-faceted approach, combining meticulous design, rigorous testing, and a commitment to regulatory adherence.

Regulatory bodies play a crucial role in this process, acting as arbiters of compliance and ensuring a fair and equitable application of standards.

Certification Process Overview, EV noise standards

The certification process for electric vehicles typically involves a series of steps, from initial design to final testing and approval. These steps are crucial in ensuring that the vehicle’s noise levels meet the prescribed standards. The process often involves submitting detailed documentation, undergoing rigorous testing, and demonstrating adherence to the stipulated criteria. Documentation usually includes detailed specifications of the vehicle’s components, including the design of the acoustic barriers and noise reduction technologies employed.

Role of Regulatory Bodies

Regulatory bodies, such as the EPA (Environmental Protection Agency) in the United States or equivalent organizations globally, are instrumental in establishing and enforcing noise standards for EVs. Their role encompasses setting the standards, conducting periodic reviews, and ensuring that manufacturers adhere to these guidelines. They also provide clear frameworks and guidelines for compliance. These bodies often conduct audits and inspections to verify compliance.

Furthermore, they play a critical role in resolving disputes and addressing any identified discrepancies in adherence to the standards. The specific regulatory body will vary based on the geographic region.

Compliance Issues and Resolutions

Occasionally, manufacturers may encounter challenges in meeting EV noise standards. These challenges can stem from various sources, including design flaws, inadequate noise reduction strategies, or limitations in testing methodologies. For instance, a vehicle might initially fail noise emission tests due to insufficient soundproofing in the wheel wells. Resolving such issues typically involves iterative design modifications and additional testing to demonstrate the vehicle’s adherence to the standards.

Collaboration between the manufacturer and the regulatory body is crucial in resolving such challenges.

Documentation Required for Certification

Comprehensive documentation is paramount for successful EV noise certification. This documentation must clearly detail the design, manufacturing process, and testing procedures used in developing the vehicle. The documentation often includes detailed schematics of the vehicle’s noise-reducing components and a thorough description of the testing methodology. This thoroughness ensures transparency and allows for independent verification of compliance. Furthermore, the documentation should include results from all required acoustic tests, along with a summary of any modifications made to address compliance issues.

Examples include acoustic measurements of the vehicle’s interior and exterior, detailed calculations of sound absorption and transmission loss of materials used, and a summary of the sound insulation strategies employed.

Recent EV noise standards are causing quite a stir, particularly in the luxury car sector. Aston Martin, known for its powerful engines, is reportedly exploring alternative ways to meet these new standards, as seen in their recent news. Aston Martin news suggests they’re experimenting with unique sound design elements to create a premium driving experience, while still complying with the noise regulations.

This approach highlights the complex challenges manufacturers face with electric vehicle sound design.

Consumer Perception of EV Noise

Consumer acceptance of electric vehicles (EVs) hinges on factors beyond just performance and range. A critical aspect is the perceived noise of the vehicle, impacting user experience and overall satisfaction. Understanding consumer preferences for EV sound is crucial for manufacturers to design quieter, more appealing vehicles.Consumer perception of EV noise is multifaceted. It encompasses not just the objective decibel level, but also the subjective experience, influenced by individual preferences, prior experiences with transportation noise, and even the context of use.

Factors such as the expected quietness of EVs, the perceived absence of an engine, and the acoustic environment of use contribute to the overall perception.

Consumer Preferences Related to EV Noise

Consumer preferences for EV noise are diverse. Some consumers desire a near-silent experience, associating it with luxury and sophistication. Others might prefer a slightly more noticeable sound, perhaps for safety or to better perceive the vehicle’s surroundings. This variability necessitates a nuanced approach to designing EV sound characteristics. Research suggests that a “perceived quietness” exceeding 60dB is often preferred, but subjective experiences vary.

This can be due to the varying background noise levels and individual sensitivities.

Impact of Noise Levels on Consumer Acceptance and Adoption

Noise levels directly influence consumer acceptance and adoption of EVs. Studies show that a perceived lack of adequate acoustic feedback can lead to a sense of unease or uncertainty for drivers, especially in low-speed or urban environments. This can negatively impact the overall experience and willingness to adopt EVs. A balanced approach is crucial, avoiding the extreme of absolute silence, which may impair driver awareness of the surroundings, and overly loud sounds, which might be disruptive or unpleasant.

For instance, certain urban settings or highway conditions may require a more noticeable sound signature.

Survey on EV Noise Preferences

Collecting direct consumer feedback is essential for refining EV sound design. The following survey aims to capture consumer perceptions of EV noise:

| Noise Level (dB) | Frequency (Hz) | Consumer Rating (1-5, 5 being highest) |

|---|---|---|

| 50 | 100-200 | |

| 60 | 100-200 | |

| 70 | 100-200 | |

| 50 | 200-500 | |

| 60 | 200-500 | |

| 70 | 200-500 | |

| 50 | 500-1000 | |

| 60 | 500-1000 | |

| 70 | 500-1000 |

Note: This survey design focuses on a range of noise levels and frequencies, aiming to understand consumer preferences across different scenarios. The survey should be deployed in diverse locations to collect a comprehensive range of feedback.

Future Trends in EV Noise Standards

Future electric vehicle (EV) noise standards are likely to evolve significantly, driven by a confluence of factors including technological advancements, consumer preferences, and regulatory pressures. The current focus on quiet operation is expected to continue, but with increasing complexity and potentially stricter targets. This evolution will require a comprehensive understanding of noise sources and effective mitigation strategies.

Predicting Future Noise Standards

Future EV noise standards will likely reflect a more nuanced approach to acoustic design. Instead of a single, universal standard, there may be variations based on vehicle type, intended use, and operating conditions. For example, urban vehicles might be subject to different standards than long-distance highway vehicles. This tailoring aims to optimize acoustic comfort and safety in diverse scenarios.

Moreover, the standards may evolve to account for different noise characteristics at varying speeds and driving conditions.

Advancements in Noise Reduction Technologies

Significant advancements in noise reduction technologies are anticipated, potentially surpassing current approaches. These improvements will involve active noise control systems that can actively cancel out unwanted noises. Furthermore, innovative materials and designs will play a crucial role in reducing noise transmission through the vehicle’s structure. Examples include advanced acoustic coatings, optimized chassis designs, and innovative sound-absorbing materials. The incorporation of sophisticated algorithms and sensors will further refine the effectiveness of noise reduction strategies.

Influence of Technological Advancements on Standards

Technological advancements in battery technology and motor design will impact noise characteristics. As battery technology improves, EVs will potentially be quieter at lower speeds, enabling a more seamless transition between electric and internal combustion engine (ICE) vehicles. Moreover, the increasing sophistication of motor technology will also affect noise profiles, potentially leading to lower operational sounds and smoother acceleration.

Potential for Stricter Noise Standards

The potential for stricter noise standards in the future is plausible. As public awareness of EV noise increases, regulatory bodies might respond by implementing stricter noise emission limits. This is especially true if the noise generated by EVs is perceived as disruptive to the surrounding environment. For example, in urban areas where noise pollution is a critical concern, stricter noise standards may become necessary.

Stricter standards will be driven by factors like environmental regulations and public feedback.

Comparison with Internal Combustion Engine Vehicles (ICEVs): EV Noise Standards

Electric vehicles (EVs) and internal combustion engine vehicles (ICEVs) differ significantly in their noise characteristics, necessitating distinct noise standards. This comparison highlights the key contrasts in noise reduction strategies and the resulting impact on the overall acoustic profile of each vehicle type.

Comparison of Noise Standards

ICEV noise standards typically focus on minimizing noise generated by the engine, exhaust, and rolling resistance. These standards often address noise levels at various speeds and operating conditions. In contrast, EV noise standards aim to address the quieter nature of EVs, focusing on minimizing the noise produced by components such as motors, power electronics, and aerodynamic elements, as well as the potential for audible sounds from the vehicle’s interaction with the road surface.

These differing approaches reflect the unique acoustic signatures of each vehicle type.

Similarities in Noise Reduction Approaches

While the specific methods differ, both EV and ICEV noise reduction efforts share common goals. Both types of vehicles employ noise-absorbing materials in their construction to reduce interior noise levels. Furthermore, both often utilize active noise control systems, although the implementation details and target noise sources vary significantly. For example, both might utilize sound-dampening materials in the vehicle’s body panels to reduce road noise.

Differences in Noise Reduction Approaches

A primary difference lies in the source of noise. ICEVs produce significant noise from the engine and exhaust system, necessitating focused mitigation strategies. EVs, on the other hand, often generate quieter operational sounds, and focus on minimizing sounds from electric motors, power electronics, and aerodynamic effects. This necessitates distinct approaches to noise reduction.

Impact on Overall Noise Profile

The contrasting approaches significantly influence the overall noise profile of the vehicles. ICEVs produce a distinct, often louder, engine noise that dominates the acoustic signature. EVs, with their reduced engine noise, create a quieter and more refined driving experience.

Table Comparing EV and ICEV Noise Levels

| Vehicle Type | Noise Level (dB(A)) | Speed (km/h) | Conditions |

|---|---|---|---|

| ICEV (Engine On) | 70-85 | 30 | Idle |

| ICEV (Engine On) | 80-95 | 60 | Cruising |

| ICEV (Engine On) | 85-100 | 90 | High Speed |

| EV (Motor On) | 50-65 | 30 | Idle |

| EV (Motor On) | 55-70 | 60 | Cruising |

| EV (Motor On) | 60-75 | 90 | High Speed |

| ICEV (Engine Off) | 40-50 | 0-30 | Idle |

Note: Values are approximate and can vary based on specific vehicle models, operating conditions, and testing procedures.

Case Studies of EV Noise Standards Implementation

Implementing noise standards for electric vehicles (EVs) requires a meticulous approach. Manufacturers must carefully consider design choices, testing methodologies, and regulatory frameworks to ensure compliance while delivering a satisfying driving experience. This section explores specific case studies to illustrate the challenges and successes in meeting these standards.Manufacturers demonstrate a variety of strategies to meet noise regulations. These approaches often involve a blend of design modifications, technological advancements, and adherence to standardized testing procedures.

Understanding these case studies provides valuable insight into the complexities and intricacies of EV noise management.

Specific EV Manufacturer Approaches

Various manufacturers have employed diverse strategies to meet noise standards. Their approaches often depend on the specific regulations in place in different markets. Successful implementation involves rigorous testing and iterative design adjustments.

Tesla’s Approach

Tesla, a prominent EV manufacturer, has adopted a multi-faceted strategy to meet noise standards. Their approach often prioritizes the integration of active noise cancellation systems. This involves sophisticated algorithms to counteract unwanted sounds within the vehicle cabin.

Volkswagen’s Strategy

Volkswagen, a major player in the automotive industry, has focused on reducing noise through the use of advanced materials and optimized vehicle structures. Their approach emphasizes the use of lightweight, yet strong materials in chassis and body panels to minimize noise transmission. This strategy reduces noise levels in the cabin and exterior.

BMW’s Implementation

BMW has implemented a comprehensive strategy, combining noise reduction technologies with careful attention to design elements. Their approach emphasizes active noise cancellation in conjunction with acoustic optimization within the vehicle’s interior. This approach combines advanced technologies with a focus on vehicle architecture.

Noise Level Compliance Data

Consistent and reliable testing procedures are critical for accurate compliance assessment. These procedures must be adhered to meticulously to ensure fair and unbiased results. This consistency is vital for the development of effective noise reduction strategies.

| Manufacturer | Model | Noise Level (dB) | Compliance Status |

|---|---|---|---|

| Tesla | Model S | 65 | Compliant |

| Volkswagen | ID.4 | 68 | Compliant |

| BMW | i4 | 62 | Compliant |

| Ford | Mustang Mach-E | 70 | Compliant |

Closing Notes

In conclusion, EV noise standards are evolving rapidly, reflecting the ongoing development of quieter and more sustainable transportation. Meeting these standards is essential for manufacturers, and understanding the regulations and associated technologies is crucial for consumers. The future of EVs depends on a harmonious balance between performance, design, and the desire for a quieter urban environment.

User Queries

What are the main types of noise considered in EV noise standards?

EV noise standards consider road noise, aerodynamic noise, and mechanical noise from the vehicle’s components.

How do noise standards affect the design of EV components?

Standards influence component design by mandating quieter motors, batteries, and chassis. Trade-offs between noise reduction and performance/cost are often considered.

What are some common noise reduction technologies used in EVs?

Common technologies include acoustic materials, sound dampening techniques, and optimized aerodynamic designs.

What is the role of consumer perception in EV noise standards?

Consumer perception plays a significant role. Manufacturers must consider consumer preferences regarding EV noise to achieve widespread adoption.